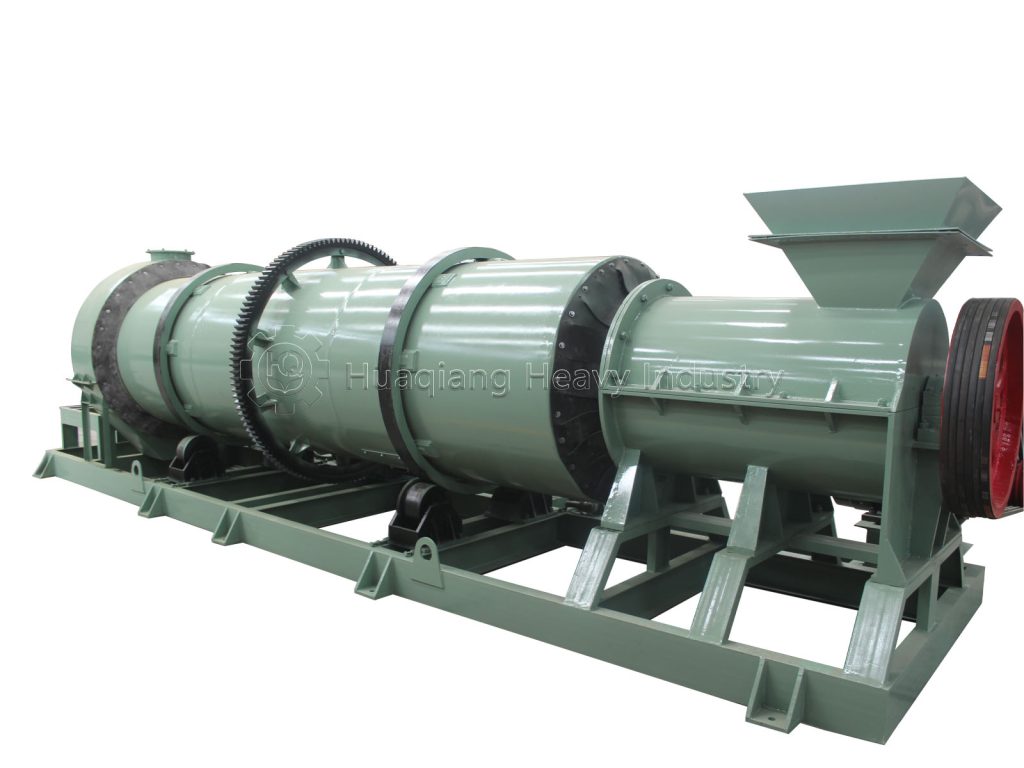

The efficiency of a new type two-in-one organic fertilizer granulator directly affects the production capacity of an organic fertilizer production line. Improper operation can easily lead to problems such as slow granulation and low pelletizing yield. Four optimization strategies can improve both efficiency and quality.

First, proper raw material pretreatment is essential. Strict control of raw material particle size and moisture is crucial: crush the fermented organic fertilizer into a 40-60 mesh fine powder to prevent coarse particles from blocking the equipment’s feed inlet and affecting mixing uniformity. The moisture content should be maintained at a stable 25%-35%. Adjust moisture content by drying or adding dry materials; spray water if too low.

Second, precise adjustment of equipment parameters is crucial. During the mixing process, adjust the agitator speed according to the raw material type: when processing high-fiber raw materials (such as straw fertilizer), adjust the speed to 50-60 rpm to increase shear force; when processing highly viscous raw materials (such as chicken manure fertilizer), reduce the speed to 20-30 rpm to prevent material from sticking to the wall. During the pelletizing process, the pelletizing method should be adjusted to suit different raw materials: for high-viscosity raw materials, use agitator pelletizing, adjusting the disc inclination to 40°-45°; for high-fiber raw materials, use roller compaction pelletizing, increasing the die pressure appropriately.After parameter adaptation, the granulation efficiency of the new type two-in-one organic fertilizer granulator can be increased by 20%-25%, and the granule forming rate is stabilized at more than 90%.

Furthermore, daily maintenance is essential. Before starting the machine daily, inspect the agitator blades and pelletizing die for wear. If blade edge wear exceeds 3mm or the die aperture is deformed, replace them promptly to avoid uneven mixing and uneven pellet sizes caused by aging components. Clean residual material inside the equipment weekly, especially the mixing chamber and the inner wall of the pelletizing disc, to prevent material agglomeration that affects subsequent production. Lubricate transmission components such as bearings and gears monthly to reduce mechanical friction and extend equipment operation.

Finally, optimizing production processes can further improve efficiency. The “immediate recycling of screen residue” model allows the screening of substandard fines directly back to the mixing system through a reflux channel, eliminating the need for manual transfer and reducing waiting time for raw materials. If the organic fertilizer production line requires continuous operation, a raw material buffer can be configured to ensure uninterrupted feeding of raw materials, avoiding frequent equipment starts and stops due to material shortages. After process optimization, the equipment’s effective daily production time can be increased by 2-3 hours, increasing overall production capacity by approximately 15%.