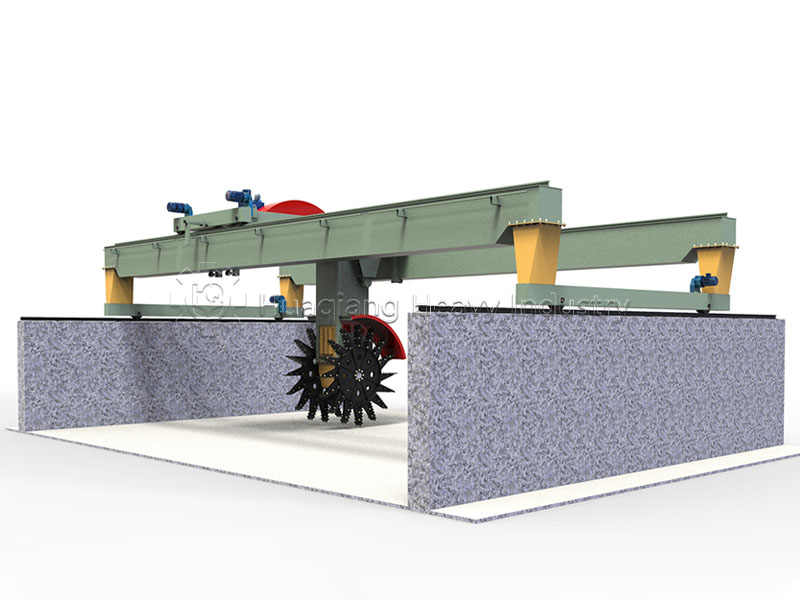

Large wheel compost turners make organic waste treatment more efficient and convenient, injecting a powerful impetus into environmental protection efforts and sparking curiosity about their many advantages.

1. Efficiently Breaks Agglomerated Materials

In organic waste treatment, materials such as livestock and poultry manure and straw often clump. The large wheel compost turner’s blades easily cut through these agglomerated materials. Whether it’s hard straw clumps or sticky livestock and poultry manure lumps, the blades quickly break them down into fine particles.

2. Deep Compost Turning Meets Diverse Needs

Large wheel compost turners typically reach a turning depth of 1.5 to 3 meters, making them suitable for organic waste fermentation projects of varying sizes and types. For large-scale organic waste treatment projects, they can penetrate deep into the bottom layer of the pile and turn the underlying material to the upper layer, ensuring sufficient oxygen supply and uniform fermentation throughout the entire pile. For small gardening farms and family farms, the turning depth can be flexibly adjusted based on actual needs to ensure effective fermentation.

3. Energy-saving Design Reduces Operating Costs

Some large wheel compost turners utilize advanced energy-saving features such as variable frequency drive. This design automatically adjusts the motor speed and power during operation based on the material’s condition and actual needs. When handling lighter, looser materials, the motor automatically reduces speed to reduce energy consumption; when handling harder, denser materials, the motor speed is increased appropriately to ensure effective turning.