In fertilizer processing, dry granulation boasts the core advantages of “no high-temperature drying and low water consumption,” making it a crucial forming technology suitable for various fertilizer types. It requires minimal moisture, relying solely on a small amount of binder and mechanical pressure to shape dry powder raw materials, simplifying the process, reducing energy consumption, and aligning with green production requirements.

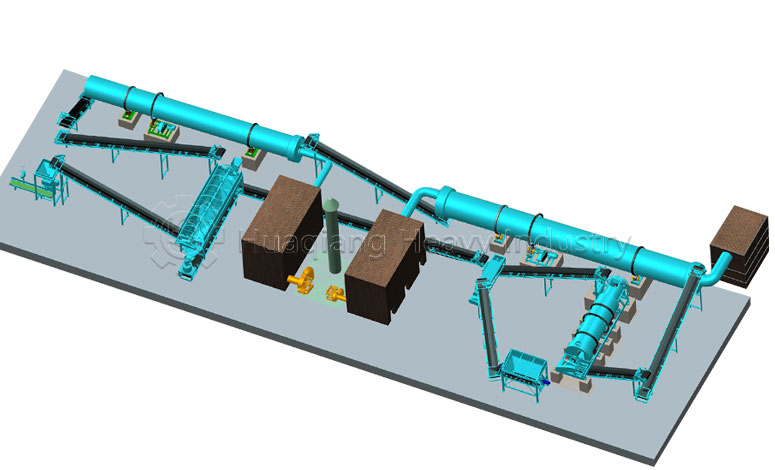

The core of the process relies on fertilizer granules compaction technology to achieve physical shaping, resulting in a simple and controllable process. First, uniformly pulverized and mixed dry fertilizer powder (such as NPK compound fertilizer or decomposed organic fertilizer powder) is fed into a fertilizer compaction machine. Pressure is applied through roller extrusion and other methods to bind the raw materials into granules. These granules are then sieved and graded, with substandard granules returned for reprocessing, forming a closed loop.

Compared to wet granulation, it offers significant energy-saving and consumption-reducing advantages, eliminating the energy consumption and equipment investment required for drying. It has low tolerance for raw material moisture, is suitable for low-moisture dry powders, avoids clumping and moisture reabsorption problems, and is more adaptable to heat-sensitive and volatile nutrient fertilizers, maximizing fertilizer efficacy.

Two key aspects need to be controlled in practical operation: First, the raw materials must be crushed to the appropriate particle size and thoroughly mixed to lay the foundation for the implementation of fertilizer granules compaction technology and ensure uniform molding; second, the pressure must be precisely controlled through the fertilizer granules compaction machine. This process is widely applicable to medium and low concentration compound fertilizers and organic-inorganic compound fertilizers, and is especially suitable for scenarios with water scarcity and high environmental protection requirements.