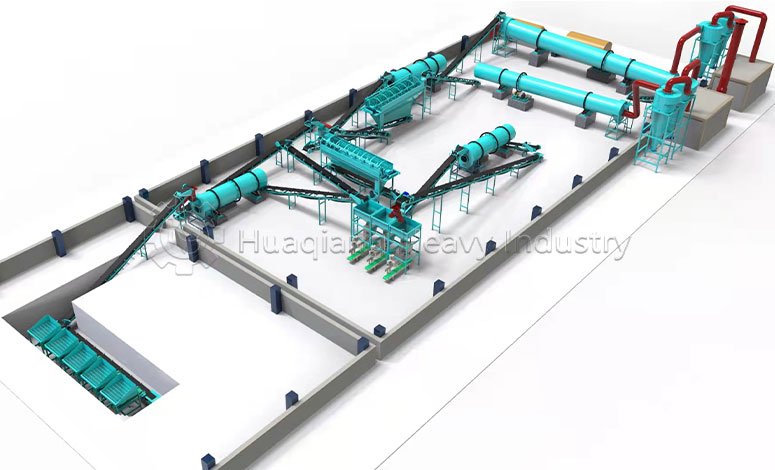

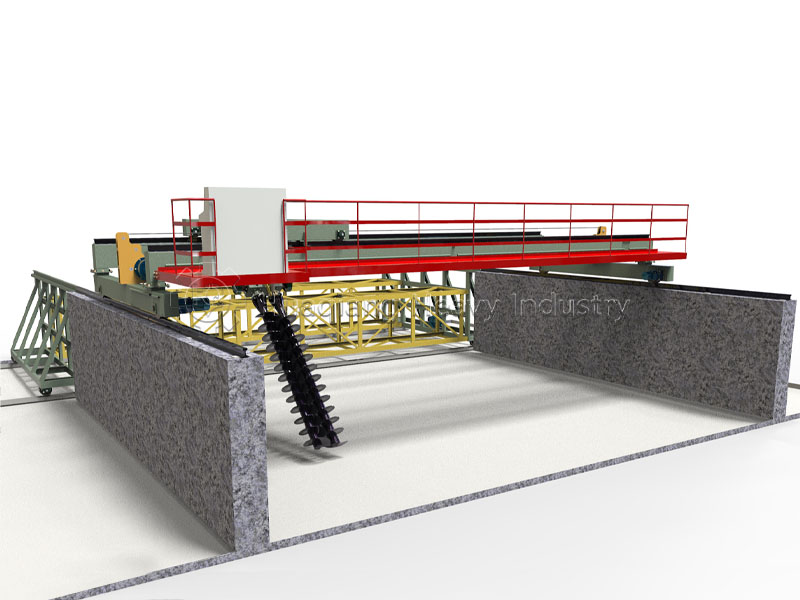

The fermentation process of large-scale organic fertilizer production (processing over 500 tons of raw materials daily) faces the challenges of high processing volume, tight fermentation cycles, and high labor costs. The double screws compost turning machine’s design features perfectly meet these requirements, making it a core piece of equipment for large-scale production.

1.Efficient and Continuous Operation

The double screws compost turning machine continuously moves along the fermentation tank, turning the compost without frequent downtime and adjustments. A single unit can process up to 100-200 tons per hour, meeting the continuous fermentation needs of large-scale production lines and ensuring timely composting.

2.Stable and Uniform Compost Turning Quality

Large-scale production requires high consistency in fertilizer quality. The double screws compost turning machine’s two spirals work in tandem, ensuring uniform mixing of the material, both vertically and horizontally, and ensuring even oxygen exposure. Fertilization temperature fluctuations are controlled within ±3°C, preventing uneven fermentation and causing uneven fertilizer quality.

3.Significantly Reduced Labor Costs

Traditional manual compost turning can only process 5-10 tons of material per person per day. A single double screws compost turning machine can replace 20-30 workers. The machine operates without human intervention (it supports automatic movement and compost turning), eliminating the efficiency fluctuations associated with manual operation.