In large-scale fertilizer production, the operating efficiency and site adaptability of organic fertilizer compost turning machines directly determine fermentation capacity. Regarding the question of whether “crawler-type compost turning machines are suitable,” the answer is yes: their core advantages precisely match the needs of large-scale production, but they require scientific application in conjunction with the production scenario. By avoiding potential shortcomings, their value can be maximized.

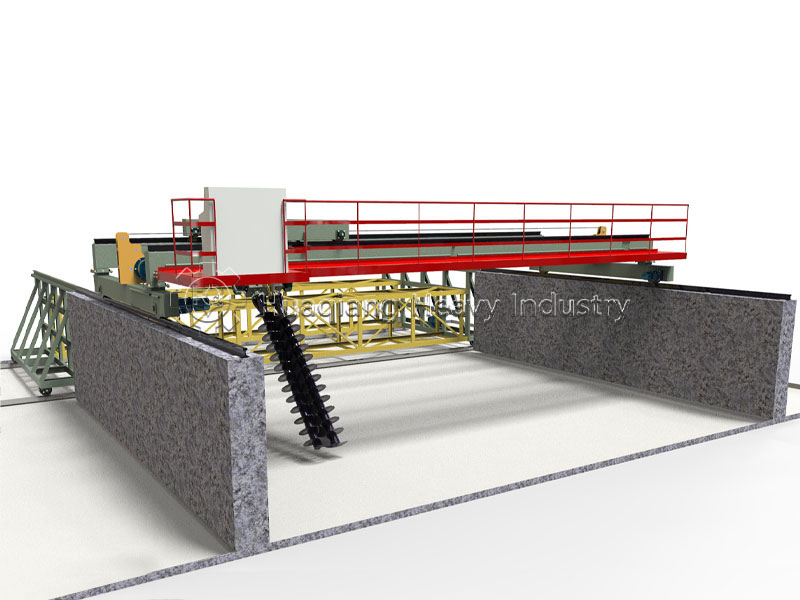

The core advantages of crawler-type compost turning machines precisely address the pain points of large-scale production. First, they have strong site adaptability; the crawler design can easily handle wide open-air fermentation areas and uneven terrain, eliminating the need for laying dedicated tracks and significantly reducing site modification costs. Second, they have high operating efficiency; the wide turning mechanism covers a large area in a single pass and has strong continuous operation capabilities. The daily processing capacity of a single machine far exceeds that of smaller compost turning machine, matching the needs of large-scale raw material turnover. Third, they provide stable turning quality; deep turning ensures uniform oxygen supply to large piles, preventing anaerobic fermentation and ensuring the quality of fertilizer maturation, laying a solid foundation for subsequent processing.

With its high efficiency, stability, and strong adaptability, the crawler-type compost turning machine is an excellent choice for large-scale fertilizer production. As a key piece of organic fertilizer production equipment, by optimizing the operating mode in conjunction with the production layout and performing proper equipment maintenance, its full potential can be realized, contributing to improved efficiency and quality in the fermentation process and supporting the smooth operation of large-scale production.