In the wave of resource utilization of agricultural waste, chicken manure is no longer a pollution hazard, but a highly valuable raw material in the fertilizer industry. Its rich nutrient reserves and suitable physical and chemical properties give it an important position in the production of high-quality organic fertilizers.

Core Value One: High-quality nutrient supply, meeting crop needs. Chicken manure is rich in core nutrients such as nitrogen, phosphorus, and potassium, and its organic matter content is as high as 25%-30%, far exceeding that of ordinary livestock and poultry manure. After scientific composting, the nutrients are more easily absorbed by crops, providing comprehensive nutrition for crop growth and supplementing soil organic matter, improving soil compaction and acidification problems.

Core Value Two: Prominent ecological value, contributing to circular agriculture. If chicken manure from large-scale farming is piled up indiscriminately, it can easily cause water and soil pollution. However, using chicken manure organic fertilizer machines to convert it into organic fertilizer can achieve a circular economy in farming, reduce the use of chemical fertilizers, and reduce agricultural non-point source pollution.

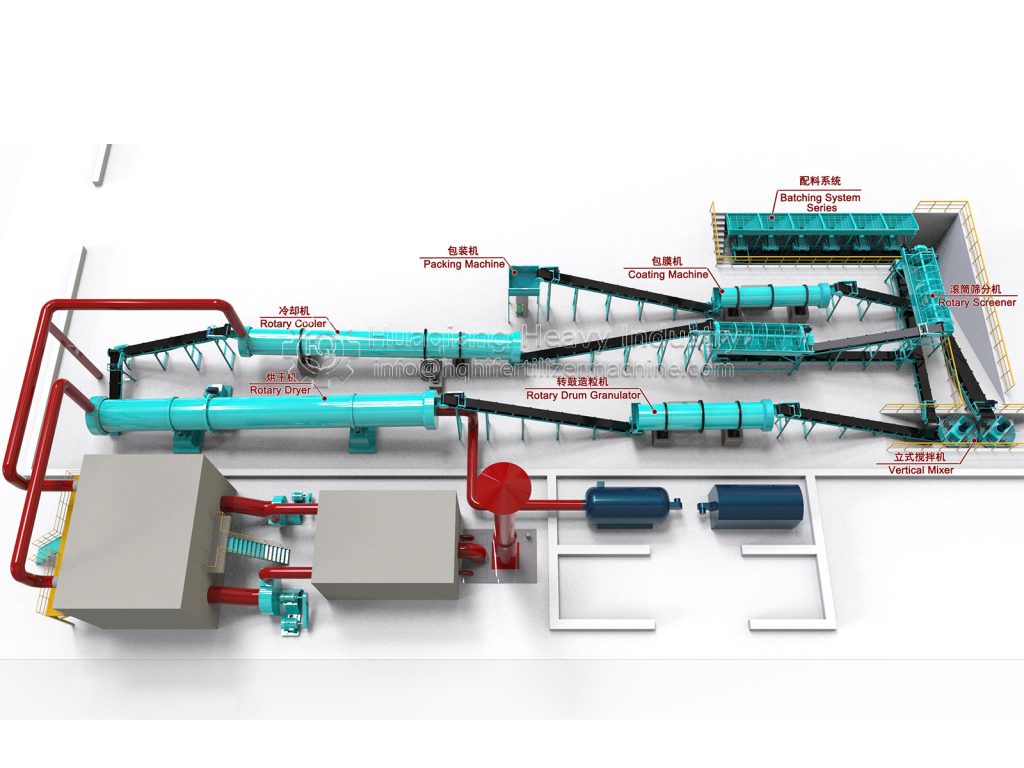

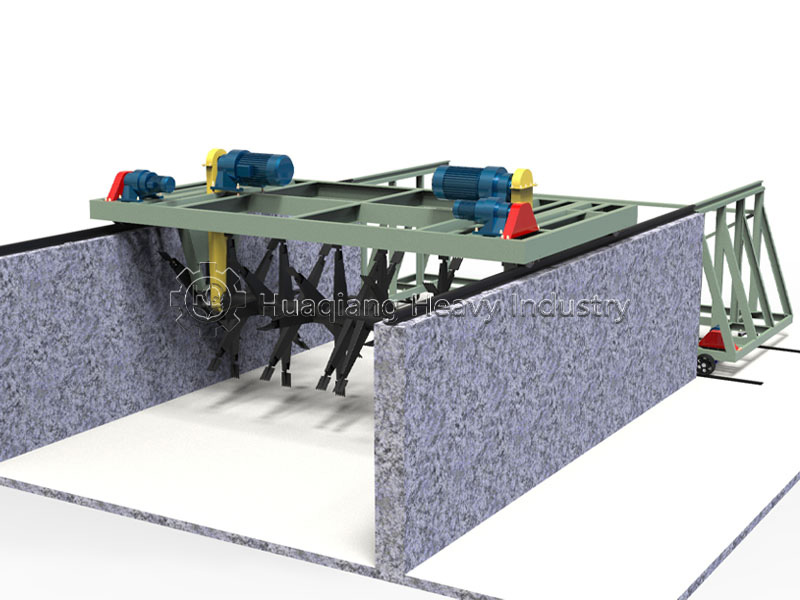

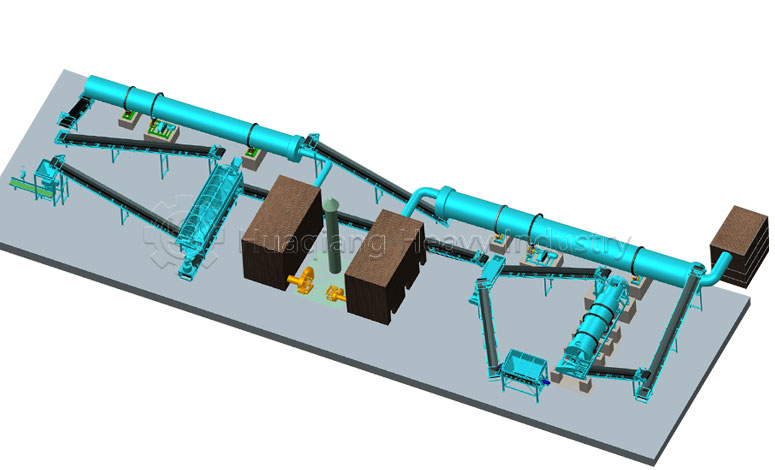

Core Value Three: Lowering production thresholds and improving economic efficiency. Chicken manure is widely available and inexpensive, which can significantly reduce the raw material costs of organic fertilizer production lines. For small and medium-sized fertilizer producers, using chicken manure as the core raw material can simplify the pre-treatment process, and high-quality organic fertilizer can be produced with conventional compost turning machines and granulators; for farmers, converting chicken manure on-site can also reduce fertilization costs and increase planting income.

The value of chicken manure in the fertilizer industry is essentially a vivid embodiment of “waste resource utilization.”

.jpg)