Applying granular fertilizer to soil is a systematic process that requires careful preparation, targeted application methods, and proper post-application care to ensure nutrients are absorbed efficiently while avoiding harm to plants. The key to success lies in tailoring the approach to the growing scenario—whether treating a large lawn or specific plants in a garden bed—and following scientific steps to maximize fertilizer effectiveness. Below is a comprehensive guide to mastering granular fertilizer application.

Adequate preparation lays the foundation for effective fertilization. First and foremost, conduct a soil test to identify the specific nutrient needs of your soil. This step prevents over-fertilization or nutrient imbalance, ensuring you select the right type of granular fertilizer. Next, calculate the required quantity by measuring the target area. For instance, a standard 12-pound bag of granular fertilizer typically covers around 4,000 square feet, so accurate measurement helps avoid waste or insufficient coverage. Additionally, never apply fertilizer when plants are wet. Wet foliage causes granules to stick, which can lead to “leaf burn” and damage plant tissue.

Choosing the appropriate application method based on the planting type is crucial for uniform nutrient distribution. For lawns or large empty beds, broadcasting is the optimal choice. Use a broadcast or drop spreader and walk at a consistent pace of approximately 3.5 mph, moving in straight, overlapping lines to ensure no area is missed or over-fertilized. For established garden plants, top-dressing works best: sprinkle granules around the base of each plant, extending to the drip line—the edge of the furthest branches—where most feeder roots are located.

For row crops such as vegetables, banding (or side-dressing) is recommended. Dig a small trench 2–3 inches to the side of the plant row and 1–2 inches deep, place the fertilizer in the trench, and cover it with soil immediately to prevent nutrient loss. When planting new specimens, base application is ideal: mix the granular fertilizer directly into the soil at the bottom of the planting hole before placing the plant, ensuring young roots can access nutrients as they grow.

Post-application steps are essential to activate the fertilizer and protect plants. In garden beds, use a hand rake or cultivator to scratch the granules into the top 1–3 inches of soil, promoting contact with moisture and roots. Regardless of the application method, water the area thoroughly right after fertilizing. This step breaks down the granules, activating the nutrients and allowing them to seep into the root zone, while also preventing chemical burns on grass or foliage. Finally, sweep any stray granules from driveways or sidewalks back into the soil to avoid nutrient runoff into storm drains, which harms the environment.

By following these structured steps—thorough preparation, scenario-specific application, and diligent post-application care—you can apply granular fertilizer to soil effectively. This approach ensures that plants receive the right nutrients in the right amounts, fostering healthy growth while minimizing waste and environmental impact. Whether tending to a sprawling lawn or a intimate garden bed, mastering these techniques makes granular fertilization a simple and rewarding part of garden maintenance.

Industrial Production: Creating the Granules for the Field

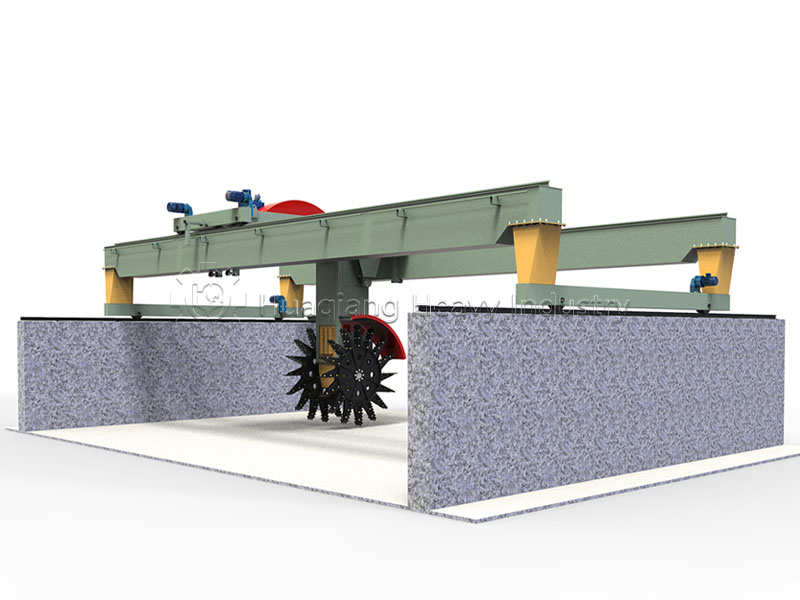

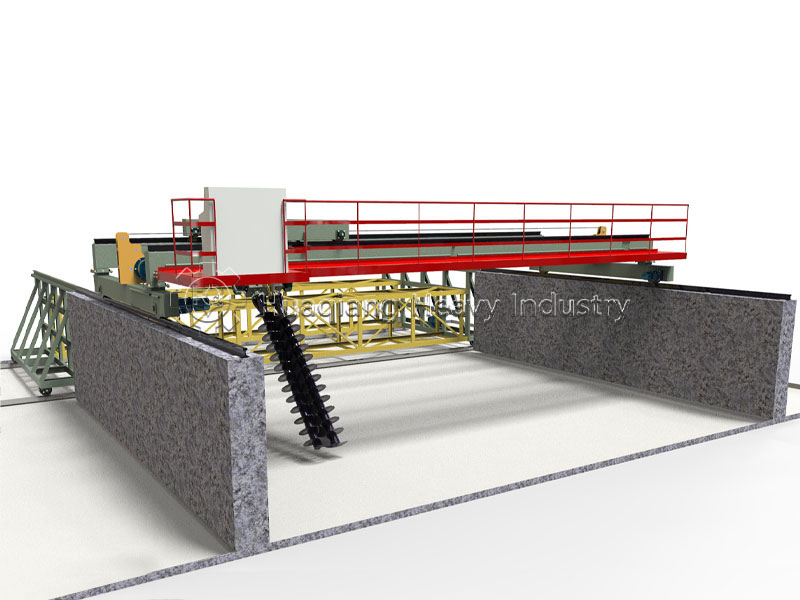

The uniform, high-quality granules applied by farmers and gardeners are the end product of sophisticated industrial processes. The ability to produce a wide range of specific NPK formulations begins with advanced npk fertilizer production technology. In the npk fertilizer manufacturing process, raw materials are first precisely proportioned and homogenized. This can be done using a npk blending machine or a fertilizer mixer machine for integrated production, or a npk bulk blending machine (a type of bulk blending fertilizer machine) for physical mixing of pre-granulated materials.

The core of the npk fertilizer production line is the granulation unit. Here, an npk granulation machine applies specific npk granulation machine technology, such as rotary drum agglomeration with a liquid binder, to form the dense, spherical granules ideal for broadcast or banding application. This entire suite of npk fertilizer granulator machine equipment—including the granulator, dryers, and coolers—is designed to produce granules with consistent size, hardness, and nutrient content, ensuring predictable breakdown and nutrient release once applied to the soil.

Therefore, the precision achieved in field application is fundamentally enabled by the precision engineered into the npk fertilizer machine during manufacturing. The industrial process ensures that every bag of fertilizer contains granules that will perform reliably, supporting the scientific soil management practices outlined for end-users.