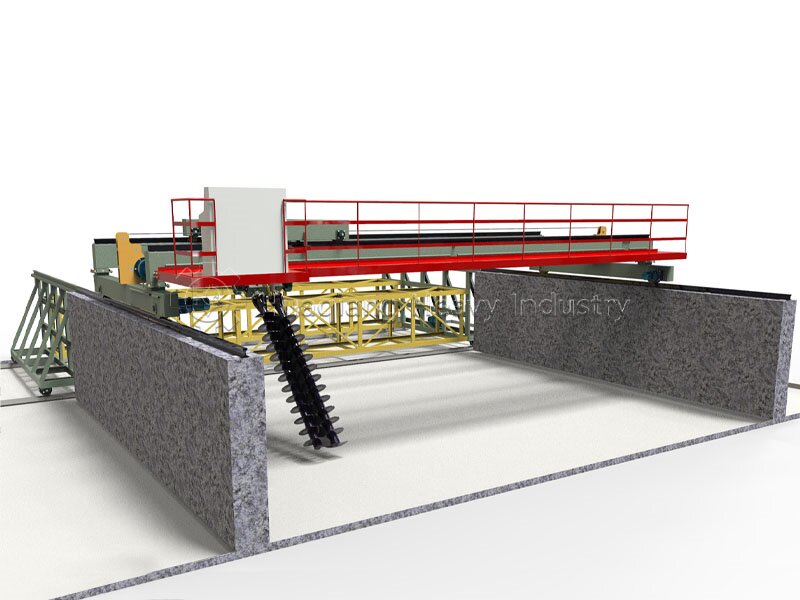

In the organic fertilizer production process, fermentation is always the core. While raw materials are laid out quietly, awaiting transformation, one piece of equipment begins to demonstrate its value—the double screws compost turning machine.

It may not be bulky, but it boasts a unique design. Two sturdy helical shafts work side-by-side, like coordinated hands, penetrating deep into the material. Rotating, lifting, and scattering, this seemingly simple action precisely brings the necessary oxygen to the compost pile while removing excess moisture and heat.

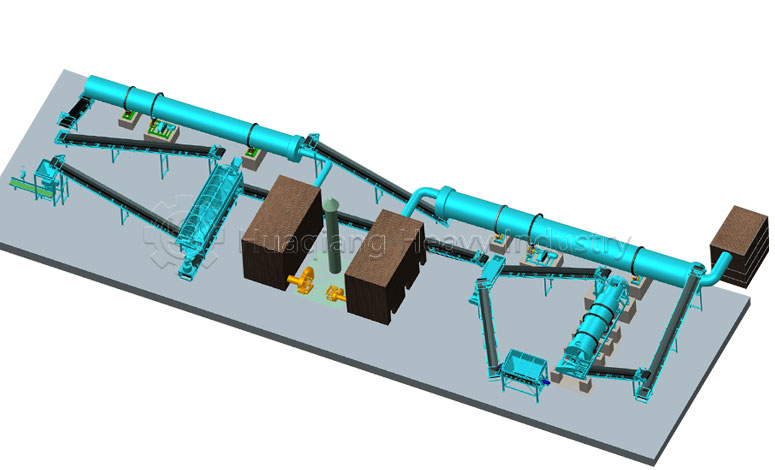

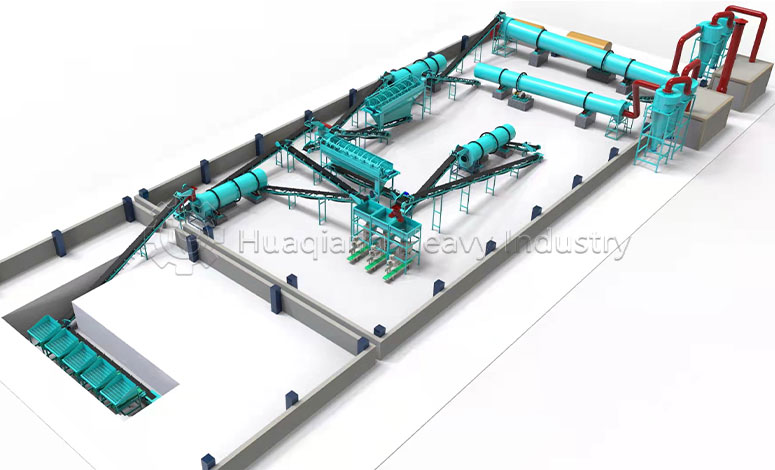

In organic fertilizer production lines, turning is crucial to the success of fermentation. Compared to traditional methods, this equipment processes materials more evenly and efficiently. It quietly moves along the long trough, loosening the previously compacted material and creating an ideal home for microorganisms.

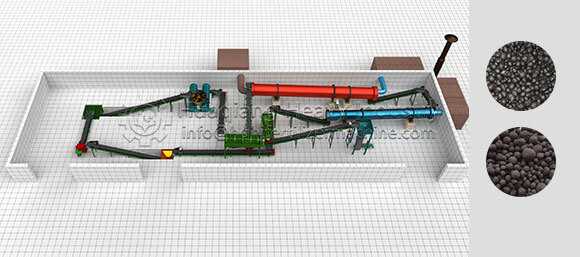

Sometimes, large wheel compost turning machines are also mentioned. They each have their own characteristics and are suitable for different sites and scales. Large wheel compost turners handle materials in their own way, while double screws compost turners excel in their precision. The choice depends on specific production needs.

As one of many organic fertilizer production equipment, the double screws compost turner is unassuming. It simply performs its mission day after day on its fixed track. But it is precisely this stability that ensures the smooth operation of the entire organic fertilizer production line, allowing waste to steadily transition to a new life.