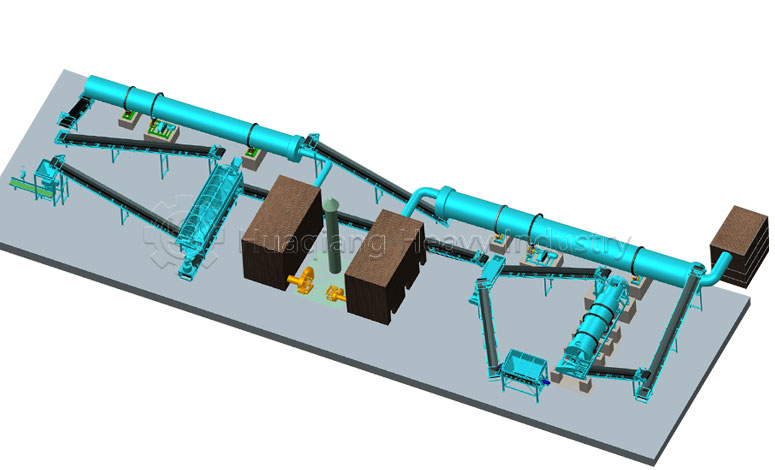

In modern organic fertilizer production, a complete production line achieves value enhancement from raw materials to finished products through the precise coordination of specialized equipment at each stage. This system transforms various organic wastes into high-quality organic fertilizers through a scientific process.

At the front end of the production line, the fertilizer crusher undertakes a crucial pretreatment task. It effectively breaks down lumps in the raw materials, ensuring the smooth progress of subsequent processes. The crushed raw materials are not only easier to mix evenly but also create favorable conditions for the subsequent fermentation process.

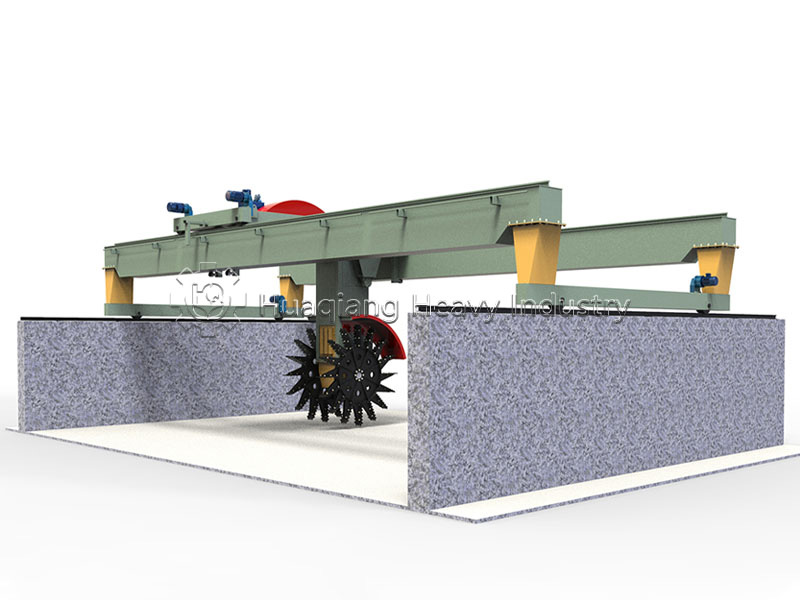

Next, the fertilizer mixer machine plays a key role. This equipment, through an efficient mixing mechanism, thoroughly mixes the raw materials of different components. This uniform mixing not only ensures a balanced distribution of nutrients but also guarantees the consistency of the fermentation process, laying a solid foundation for the production of high-quality organic fertilizer.

After the material has completed fermentation, the organic fertilizer granulator becomes the core equipment of the production line. Through unique molding technology, it transforms powdery materials into uniformly sized granular products. This transformation not only improves the product’s marketability but also gives it significant advantages in storage, transportation, and application.

The successful operation of the entire organic fertilizer production line relies on the precise coordination of each piece of equipment. From crushing and mixing to granulation, each step is closely linked, forming a highly efficient production system. This systematic production method not only ensures the stability of product quality but also greatly improves production efficiency.