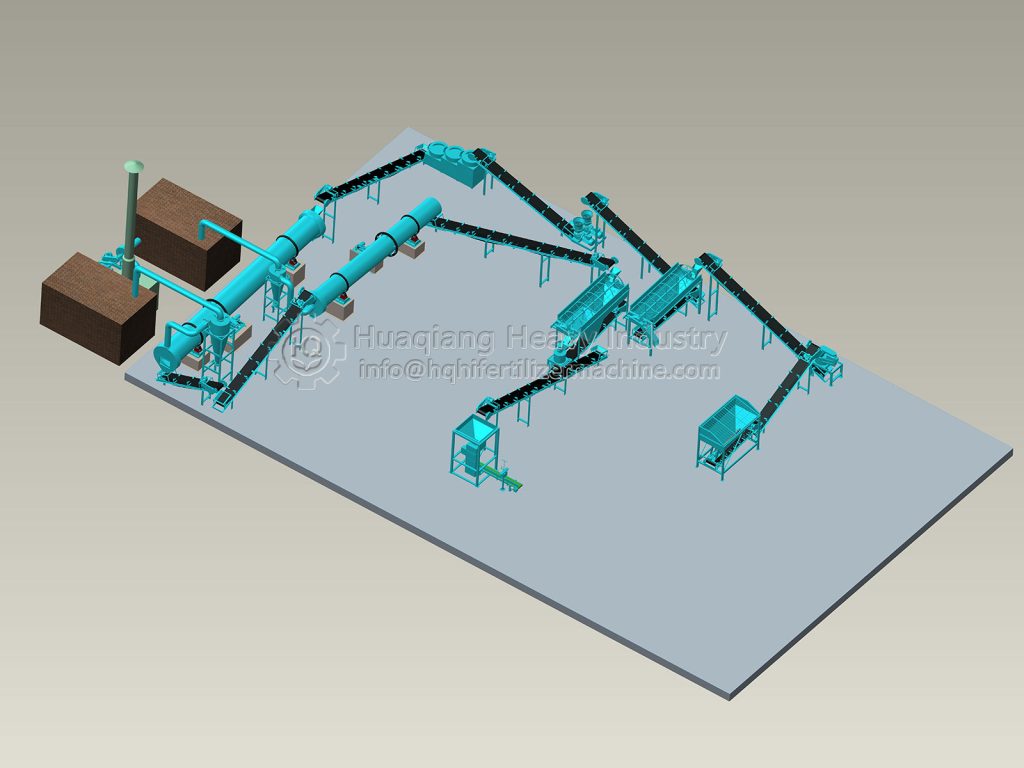

In a modern factory, a bio-organic fertilizer production line is quietly operating. Here, there’s no pungent odor like in traditional fertilizer plants, only the rhythmic sounds of equipment, witnessing the entire process of transforming organic waste into treasure.

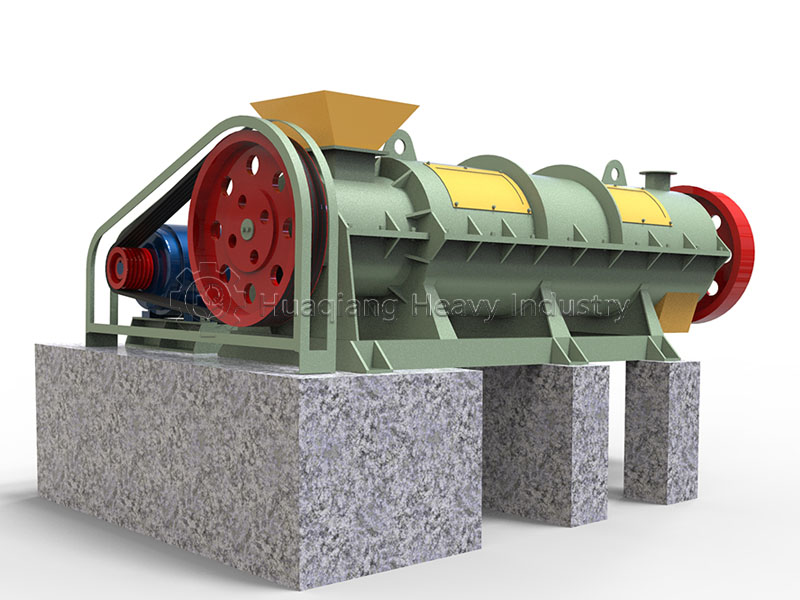

After being scientifically proportioned, the raw materials enter the core granulation section. The new type organic fertilizer granulator demonstrates its unique value: without chemical binders, it uses precisely designed physical pressure to shape loose fermented materials into uniform and firm granules. These black granules are convenient for storage and transportation, and also allow for the slow release of nutrients into the soil.

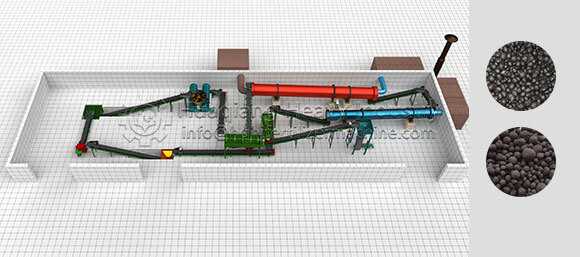

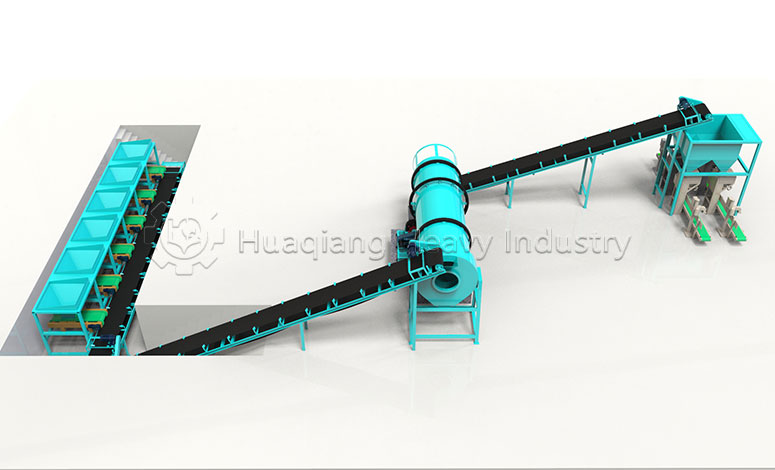

The coordinated operation of the entire bio-organic fertilizer equipment is impressive. From raw material crushing and fermentation to granulation and drying, each step is meticulously designed. In particular, the new type organic fertilizer granulator can flexibly adjust the particle size and hardness to meet the needs of different crops and soils.

In the finished product workshop, the granulated fertilizer, after strict quality inspection, is automatically weighed and packaged. These black granules, transformed from waste, are about to begin a new mission—returning to the earth, improving soil structure, and providing lasting nutrients for crop growth.

This production line is not only a demonstration of technology, but also a vivid example of circular agriculture. It gives new life to agricultural waste, transforming pollutants into nutrients. Behind these seemingly ordinary black granules lies the wisdom of sustainable development in modern agriculture.