Potassium nitrate, as a high-quality and efficient fertilizer containing both essential nitrogen and potassium nutrients, plays a significant role in modern agriculture. Its production process is primarily based on chemical reaction principles, transforming raw materials into high-purity potassium nitrate products through different technological routes.

I. Main Production Process: Double Decomposition Method

The double decomposition method is currently the most commonly used production process for potassium nitrate, offering advantages such as readily available raw materials, moderate costs, and suitability for large-scale production. The core of this process involves using the double decomposition reaction of two salts in aqueous solution to generate the target product.

Detailed Process Flow:

The process begins with raw material preparation, mainly using sodium nitrate and potassium chloride, proportioned according to precise chemical stoichiometry. The raw materials are then dissolved in water and stirred at specific temperature conditions to generate potassium nitrate and sodium chloride.

The key step lies in the cooling crystallization stage, where engineers skillfully utilize the significant temperature-dependent solubility characteristics of potassium nitrate. By controlling the cooling process, potassium nitrate preferentially crystallizes. Subsequently, potassium nitrate crystals are separated from the impurity-containing mother liquor through filtration or centrifugal separation equipment.

The separated crystals undergo multi-stage washing to remove surface impurities, followed by hot air drying to eliminate moisture, ultimately obtaining high-purity potassium nitrate powder. According to market demand, this powder can be further processed into granular products, which are then measured, packaged, and distributed to the market.

.jpg)

II. Alternative Production Process: Nitric Acid-Potassium Chloride Method

For regions with access to inexpensive nitric acid resources, the nitric acid-potassium chloride method provides a more direct production pathway. This method has a relatively simpler process flow but requires higher corrosion resistance for the equipment.

Process Characteristics:

This process directly uses concentrated nitric acid and potassium chloride as raw materials, conducting neutralization reaction in specialized corrosion-resistant reaction equipment to produce potassium nitrate and hydrochloric acid. The by-product hydrochloric acid is effectively separated through distillation or extraction processes, which not only prevents affecting product purity but also enables resource recycling.

The remaining potassium nitrate solution undergoes concentration, cooling crystallization, filtration, washing, and drying processes to obtain finished fertilizer products that meet standards. This method is particularly suitable for integration with nitric acid production enterprises, achieving optimal resource allocation.

III. Key Control Points in Production Process

Regardless of the production process used, several key parameters must be strictly controlled to ensure final product quality and production efficiency.

Temperature Control: In the double decomposition method, reaction temperature directly affects reaction rate and completeness, while temperature control precision during the crystallization stage determines product yield and quality. Typically, temperature fluctuations need to be controlled within ±2°C.

Purity Control: By optimizing washing processes and employing recrystallization technology when necessary, impurities such as sodium chloride and chlorides can be effectively removed, ensuring potassium nitrate content meets agricultural fertilizer standards (usually requiring ≥98%). Advanced production lines are also equipped with online monitoring systems for real-time product quality supervision.

Environmental Protection and Resource Utilization: Modern potassium nitrate production places special emphasis on environmental protection and comprehensive resource utilization. Treatment of mother liquor and wastewater generated during production, along with recovery of valuable components such as sodium chloride by-products, not only reduces production costs but also minimizes environmental pollution.

IV. Process Selection and Development Trends

The selection of production process mainly depends on factors such as raw material availability, investment scale, and environmental requirements. The double decomposition method has become the mainstream choice due to its technological maturity and strong adaptability, while the nitric acid-potassium chloride method demonstrates competitive advantages under specific resource conditions.

Current development trends in potassium nitrate production technology are mainly reflected in increased automation, reduced energy consumption, and enhanced environmental protection. New crystallization technologies and separation equipment are continuously being introduced into production practices, resulting in more stable product quality and continuously optimized production costs.

With the growing global demand for efficient and environmentally friendly fertilizers, potassium nitrate fertilizer production technology will continue to develop in greener and more efficient directions, providing important material support for sustainable agriculture.

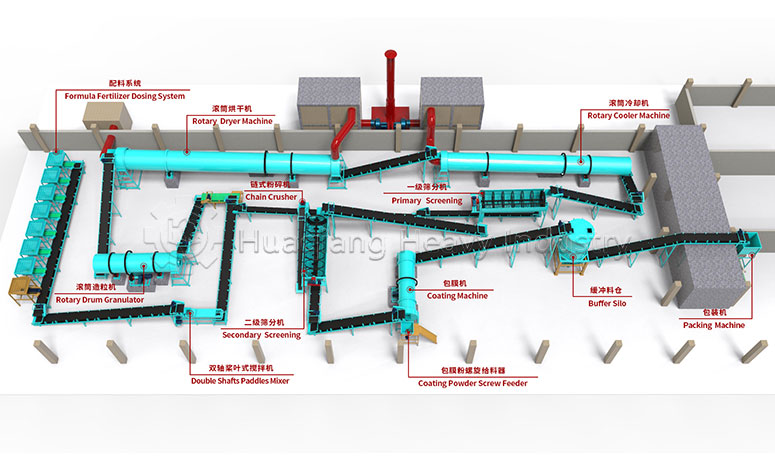

Conclusion: Advancing Fertilizer Production Technology

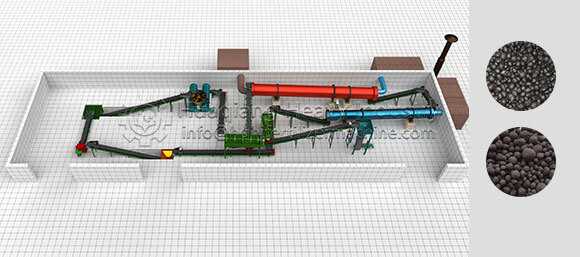

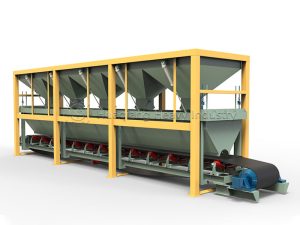

The npk fertilizer manufacturing process has evolved significantly to meet modern agricultural demands. While potassium nitrate production demonstrates sophisticated chemical processing, the broader npk fertilizer production line incorporates specialized equipment for optimal nutrient delivery. The npk blending machine and fertilizer mixer machine ensure precise nutrient ratios, while granulation equipment like the npk fertilizer granulator machine and disc granulator machine transform powder mixtures into uniform granules. The npk granulation machine technology has become particularly crucial in the manufacturing of npk fertilizer, with the disc granulator offering efficient fertilizer granulation for enhanced product performance.

For operations requiring flexibility, the bulk blending fertilizer machine and npk bulk blending machine provide customized nutrient combinations. The complete npk fertilizer machine system integrates both the npk production process and complementary technologies like fermentation composting technology for organic fertilizer. As the industry advances, the npk fertilizer production process continues to incorporate automation and precision engineering, making the npk manufacturing sector more efficient and environmentally sustainable. These technological improvements in npk fertilizer granulator systems and overall production methodologies ensure high-quality fertilizers that support global food security while minimizing environmental impact.