NPK blending, a crucial process in fertilizer production, involves mixing pre-manufactured solid fertilizer particles to create customized nutrient formulations tailored to specific soil and crop needs. Unlike synthetic NPK production that involves chemical reactions, the raw materials for NPK blending are finished granules or prills that undergo no further chemical transformation. These materials are systematically categorized based on the nutrients they provide, supplemented by additives and fillers to optimize performance. Understanding the composition of these raw materials and their quality requirements is essential for producing effective, stable NPK blends.

The core raw materials for NPK blending are classified by their primary nutrient contribution: nitrogen (N), phosphorus (P), and potassium (K). Nitrogen sources form the foundation of many blends, with urea being the most widely used due to its high nitrogen content (46%), making it cost-effective and efficient for boosting foliage growth. Ammonium sulfate is a popular alternative, especially for sulfur-deficient soils, as it provides both nitrogen and sulfur. Ammonium nitrate, though common for its high nutrient density, requires careful handling due to safety considerations. Ammonium chloride serves as another nitrogen source option in pellet form, suitable for specific crop and soil conditions.

Phosphorus sources often double as dual-nutrient ingredients, enhancing the versatility of blends. Diammonium Phosphate (DAP) is a staple, offering both nitrogen and a high concentration of phosphorus, ideal for supporting root development and reproductive growth. Monoammonium Phosphate (MAP) is another widely used dual-nutrient granular material, valued for its stable properties and balanced nutrient ratio. For phosphorus-focused formulations, Triple Superphosphate (TSP) provides a concentrated phosphorus supply, while Single Superphosphate (SSP) offers lower phosphorus levels alongside additional sulfur, addressing multiple nutrient needs simultaneously.

Potassium sources are selected based on cost and crop sensitivity. Muriate of Potash (MOP), or potassium chloride, is the most common and economical option, providing roughly 60% potassium. However, for chloride-sensitive crops such as strawberries, potatoes, and citrus fruits, Sulfate of Potash (SOP) is preferred, as it delivers potassium without the harmful effects of chloride, ensuring crop health and quality.

To address specific soil deficiencies and improve overall plant health, blenders frequently incorporate secondary and micronutrients. Secondary nutrients include magnesium sulfate (kieserite), which supports chlorophyll formation; gypsum (calcium sulfate), which enhances soil structure and provides calcium; and dolomitic limestone, which regulates soil pH while supplying calcium and magnesium. Micronutrients, added in trace amounts, are critical for balanced plant growth, with common options including zinc, iron, manganese, boron, and copper—each playing a unique role in enzyme function and nutrient uptake.

Additives and fillers are essential for fine-tuning NPK blends and improving their physical properties. Fillers such as limestone, dolomite, and bentonite adjust the final product’s weight to meet target NPK ratios and regulate soil pH, ensuring compatibility with different growing environments. Coating agents are applied to prevent moisture absorption and clumping, enhancing the storage stability and handling efficiency of the blend, which is particularly important for bulk transportation and long-term storage.

Critical quality factors ensure the effectiveness of NPK blends, with physical compatibility being paramount. All raw material granules must be roughly the same size (typically 2–4mm) to prevent segregation during transport and application, ensuring uniform nutrient distribution. Moisture content is another key requirement—materials must be dry to avoid unwanted chemical reactions, clumping, or nutrient loss in the mix. These quality standards guarantee that the final blend performs consistently, delivering the intended nutrient benefits to crops.

In summary, NPK blending relies on a diverse range of finished fertilizer particles, secondary nutrients, micronutrients, and additives. The careful selection and combination of these raw materials, based on nutrient needs and physical compatibility, enable the production of customized blends that support sustainable agriculture. By adhering to strict quality requirements and tailoring formulations to specific soil and crop conditions, NPK blending ensures that plants receive balanced nutrition, maximizing yields and promoting long-term soil health.

From Blending to Integrated Granulation Production

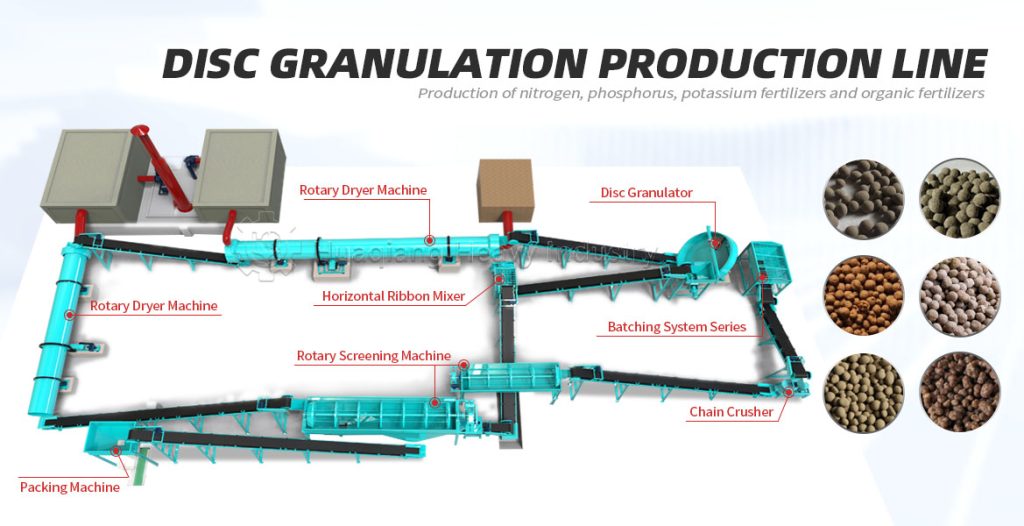

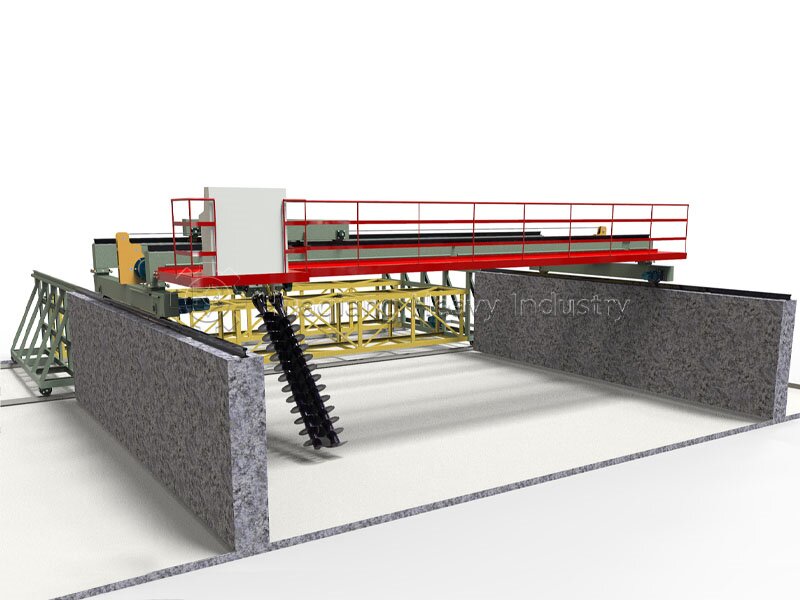

The physical blending of pre-granulated materials is executed using specialized equipment like a npk bulk blending machine or a standard npk blending machine. These machines, which are essentially high-capacity fertilizer mixer machine units, homogenize different granular components without chemical change, relying on the uniform size and moisture of the raw materials. This process is distinct from the integrated npk fertilizer manufacturing process that involves chemical granulation. For producing chemically homogeneous NPK granules from raw powders, the industry relies on advanced npk fertilizer production technology, which centers on an npk granulation machine.

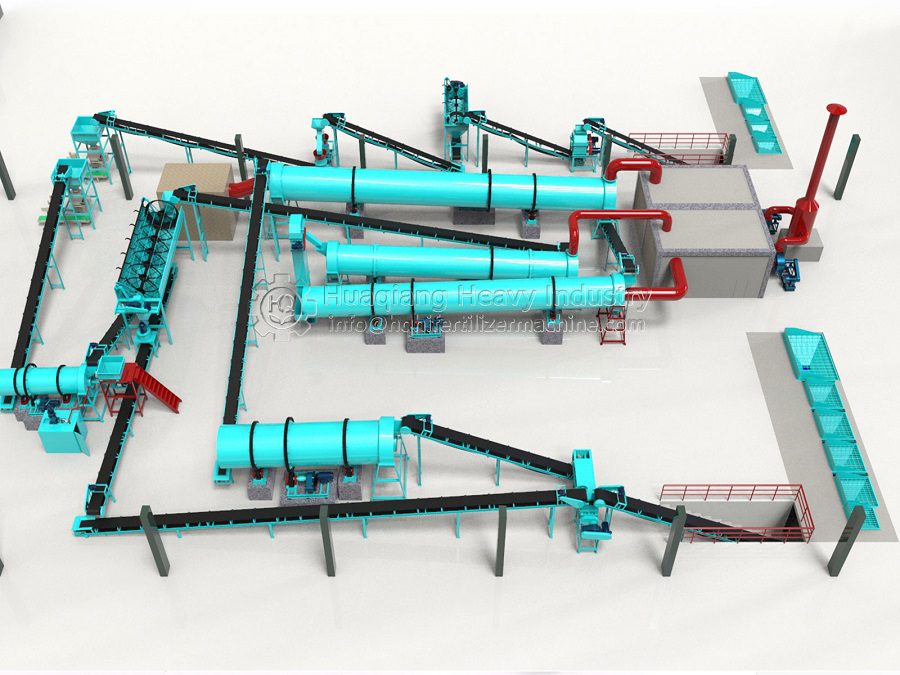

This granulation stage is the core of a complete npk fertilizer production line. The npk granulation machine technology can vary, commonly utilizing a rotary drum or pan agglomeration process where a liquid binder is sprayed onto tumbling powder. The entire suite of npk fertilizer granulator machine equipment, including mixers, granulators, dryers, and coolers, transforms raw materials into uniform, durable pellets. While a bulk blending fertilizer machine creates a physical mixture, the sophisticated npk fertilizer machine for chemical granulation creates a single, integrated granule where all nutrients are fused together, often resulting in better physical properties and nutrient synchronization.

Therefore, the choice between using blending equipment or a full granulation line depends on the desired product characteristics, raw material availability, and investment scale. Both are essential npk fertilizer production technology pathways serving different market segments within the compound fertilizer industry.