In numerous industries such as mining, building materials production, chemical processing, and grain storage, vertical material lifting is a crucial link connecting different production stages. As a mechanical device specifically designed for the continuous vertical conveying of bulk materials, the bucket elevator, with its unique bucket-type conveying structure, can efficiently lift bulk or small-piece materials such as coal, ore, cement, and grain from low to high places, becoming a core piece of equipment in industrial production for bridging vertical heights and optimizing material flow. Its continuous and stable lifting capacity solves the problem of conveying materials with high drops, providing reliable vertical conveying guarantees for large-scale production.

The stable and efficient operation of the bucket elevator relies on a scientifically sound structural design, with each core component working in tandem to form a complete lifting system. The buckets (barrels) are the core components that carry the materials, and their shape and size are precisely designed according to the material characteristics—deep buckets are used for granular materials, while shallow buckets or buckets with pointed bottoms are used for powdery materials, ensuring stable loading and thorough unloading. The traction component comes in two types: chain and belt. It connects the buckets and provides lifting power. The chain type is suitable for heavy-duty and high-temperature conditions, while the belt type is suitable for conveying lightweight materials. The drive unit consists of a motor, reducer, and drive sprocket (or drive roller), providing stable driving force to the traction component. The speed is adjusted by the reducer to adapt to different lifting rhythms. The feed inlet is located at the bottom of the equipment, facilitating smooth material entry into the buckets; the discharge outlet is located at the top, ensuring accurate discharge of the lifted material. The support and frame provide stable structural support for the entire equipment, resisting vibration and load during the lifting process and ensuring stable operation. The tensioning device can flexibly adjust the tension of the traction component to prevent slippage or slack during operation; guiding devices such as guide wheels and guide rails guide the buckets to rise and fall smoothly along a fixed trajectory, preventing deviation and collision.

The bucket elevator operates on a simple and efficient principle, achieving continuous conveying through a cyclical process of “loading-lifting-unloading-returning.” During operation, material first enters the waiting hopper through the bottom feed inlet, completing the loading process. Then, the drive unit starts, using a traction component to propel the hopper smoothly upwards along the guide rail or groove, with the material rising synchronously. During this process, the enclosed lifting space effectively prevents material spillage. When the hopper reaches the upper part of the equipment, it automatically tilts under gravity or centrifugal force, emptying the material through the discharge port to a designated location. The empty hopper then returns along the other guide rail to the bottom feed inlet, ready for the next loading cycle. The entire process is continuous and uninterrupted, ensuring both lifting efficiency and orderly material transfer.

The unique structure and working principle give bucket elevators many significant advantages, making them adaptable to the vertical conveying needs of various industries. High lifting height is its core competitive advantage, enabling it to achieve significant vertical lifting heights, perfectly suited for conveying scenarios requiring traversing large height differences, such as high-rise buildings and elevated silos. With outstanding high-efficiency lifting capacity, bucket elevators achieve highly efficient vertical material transfer through continuous bucket circulation, far exceeding the efficiency of traditional vertical conveying equipment and adapting to large-scale production rhythms. They are highly adaptable, handling various bulk or small-piece materials such as coal, ore, cement, and grain. By changing the bucket type and traction components, they can flexibly adapt to different material characteristics and operating conditions. Excellent sealing performance is another major highlight; the enclosed lifting channel effectively reduces material loss and dust emission, making it particularly suitable for dust-sensitive industries such as chemicals and grain processing. The vertical layout makes it compact, occupying only 1/5 to 1/3 of the floor space of horizontal conveying equipment, greatly saving space and making it suitable for production environments with limited space. Furthermore, the equipment structure is relatively simple, core components are easy to inspect and replace, daily maintenance is convenient, and long-term operating costs are low.

From ore lifting in mines to cement transfer in building material plants, from raw material transportation in chemical plants to grain storage in grain warehouses, bucket elevators, with their core advantages of high efficiency, stability, and compactness, provide strong support for vertical material conveying in various industries. Against the backdrop of industrial production transforming towards intensification and efficiency, this core equipment focused on vertical conveying not only optimizes the production process layout and improves production efficiency, but also aligns with the development trend of environmentally friendly production, becoming an important basic equipment for promoting the upgrading of material conveying systems in various industries.

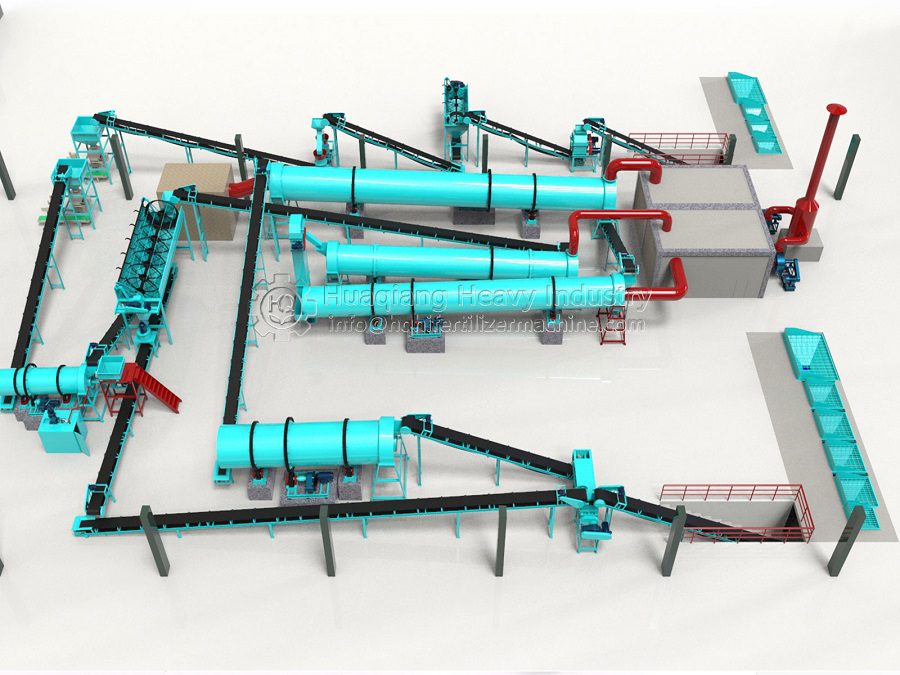

Material Flow and Granulation in Fertilizer Manufacturing

Bucket elevators are a quintessential example of the essential conveying equipment in fertilizer production line. They form a vital link within a complete professional fertilizer manufacturing equipment setup, vertically transferring raw materials like crushed ore, powdered fertilizers, or pre-processed compost between different stages. For instance, in an npk fertilizer production process, a bucket elevator may lift blended powder from a npk bulk blending machine to the feed hopper of a granulator. Similarly, in an organic fertilizer production line, it can convey cured compost from a windrow composting machine (or windrow machine) to the granulation unit.

This reliable vertical transport enables efficient feeding into the core shaping equipment. The material may be directed to a disc granulator (part of a disc granulation production line), where the disc granulator for shaping forms spherical pellets. Alternatively, it could feed a double roller press granulator in a roller press granulator production line for compaction granulation, or even a flat die pelleting machine. These fertilizer raw material processing machinery and equipment units—whether for an npk fertilizer production line or a bio organic fertilizer production line—rely on seamless material handling to ensure continuous, high-volume output.

Therefore, the integration of robust conveying systems like bucket elevators with specialized granulators such as the disc granulator machine is fundamental. It creates a synchronized, automated flow that maximizes the efficiency of the entire fertilizer manufacturing operation, from raw material intake to finished product dispatch.