The investment value of a large wheel compost turning machine depends primarily on the scale of composting, material characteristics, and site conditions; it’s not suitable for all scenarios. With its advantages of high-efficiency coverage and large-scale processing, it offers outstanding cost-effectiveness in medium-sized and larger composting projects. However, it’s crucial to avoid the pitfalls of “using a large machine for a small project” or inappropriate composting.

The return on investment is significant. For livestock manure and straw composting projects with a daily processing capacity of 200-500 cubic meters, a single large wheel compost turning machine can meet the demand, achieving a capacity utilization rate of over 90%, eliminating the need for multiple machines operating in clusters. Compared to large chain compost turning machines, its initial investment is only 1/3 to 1/2 of the former, and its energy consumption is lower.

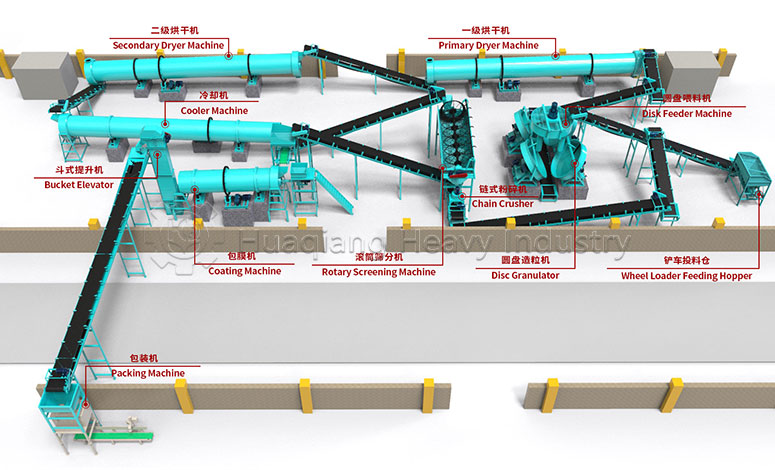

Adaptability and automation enhance investment value. The machine’s compact design and small turning radius make it suitable for small to medium-sized fermentation sites, requiring no large-scale modifications and saving on site construction costs. The disc’s crushing tooth design can break up material clumps, making it suitable for mixed materials with a solids content of 30%-50%. Equipped with an intelligent control system, it can replace manual labor, reducing labor costs and is suitable for organic fertilizer production lines.

However, investment risks due to limitations in adaptability should be considered. For small projects (daily processing capacity <100 cubic meters), its use may lead to wasted capacity. High-moisture, high-viscosity materials can easily cause the discs to entangle, requiring pre-treatment and increasing costs. Furthermore, the equipment has certain requirements for site flatness; it is less suitable for narrow or indoor spaces, and blind investment may lead to inefficiency.

In summary, large wheel compost turning machines are worth investing in for medium-scale, loosely packed composting scenarios with open spaces, balancing efficiency and cost. If tailored to specific production capacities and material characteristics, the long-term cost savings and efficiency improvements will far outweigh the initial investment.