In organic fertilizer production lines, there’s a seemingly simple yet crucial process: extrusion granulation. It transforms loose, uneven powdered organic raw materials into uniform, solid granules. This isn’t just a change in form; it’s a crucial step in improving the quality and modernizing the development of organic fertilizer.

Although rich in nutrients, unprocessed powdered organic fertilizer faces numerous challenges in practical application. First, its low density and bulk increase storage and transportation costs. Second, during application, powdered fertilizer is easily dispersed by the wind, resulting in fertilizer loss and environmental pollution. Extrusion technology specifically addresses these issues.

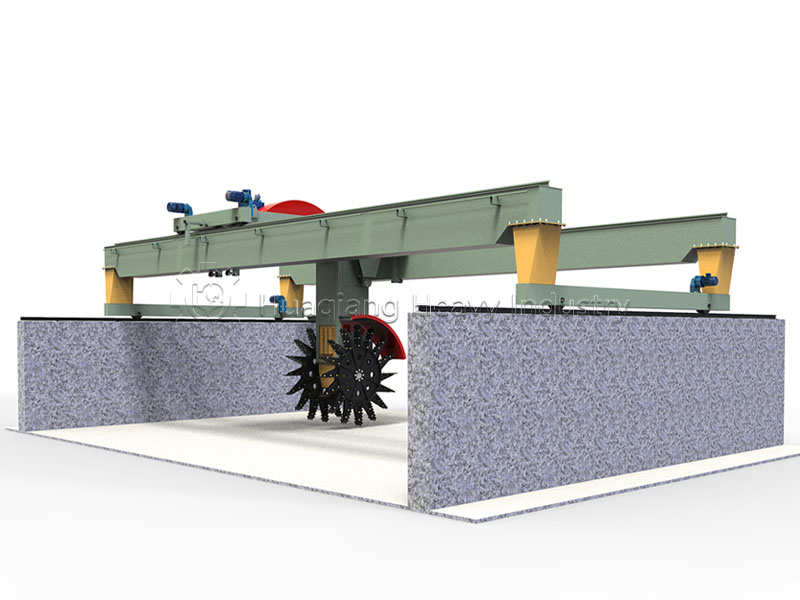

The extrusion process applies tremendous pressure to a fertilizer granulator, forcing the fine fertilizer powder through a specialized die, where it is squeezed into uniform, high-density, and strong granules.

The widespread adoption of extrusion granulation technology marks a significant shift in the organic fertilizer industry from extensive to refined, and from traditional to modern. This enables the standardization and commercialization of organic fertilizer products, shedding their image as “earth-based fertilizer” and making them more readily accepted and trusted by large-scale farms and specialized agricultural practitioners.

In short, these tiny fertilizer pellets embody not only rich organic matter but also the wisdom of modern processing technology. Extrusion molding, as a core component, continues to provide solid technical support for improving quality, increasing efficiency, and promoting green development in the organic fertilizer industry.