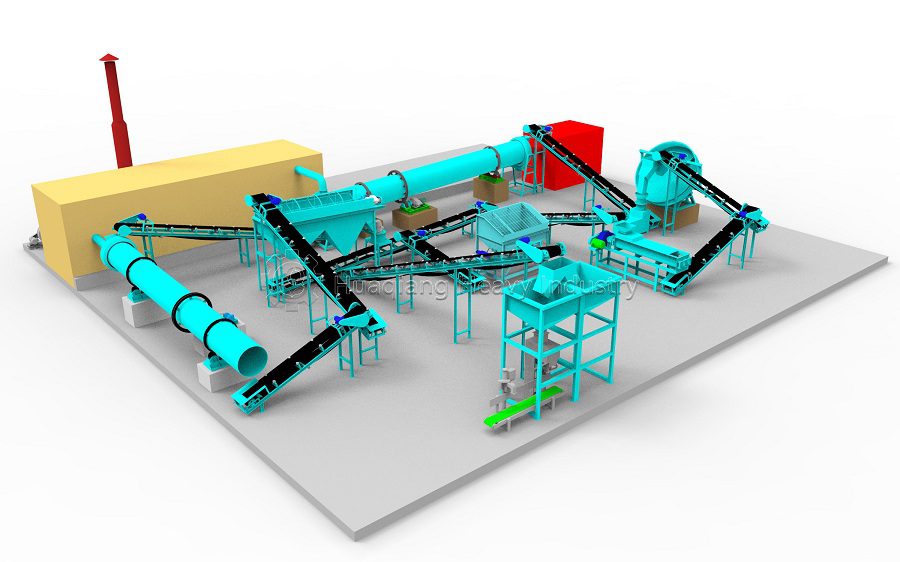

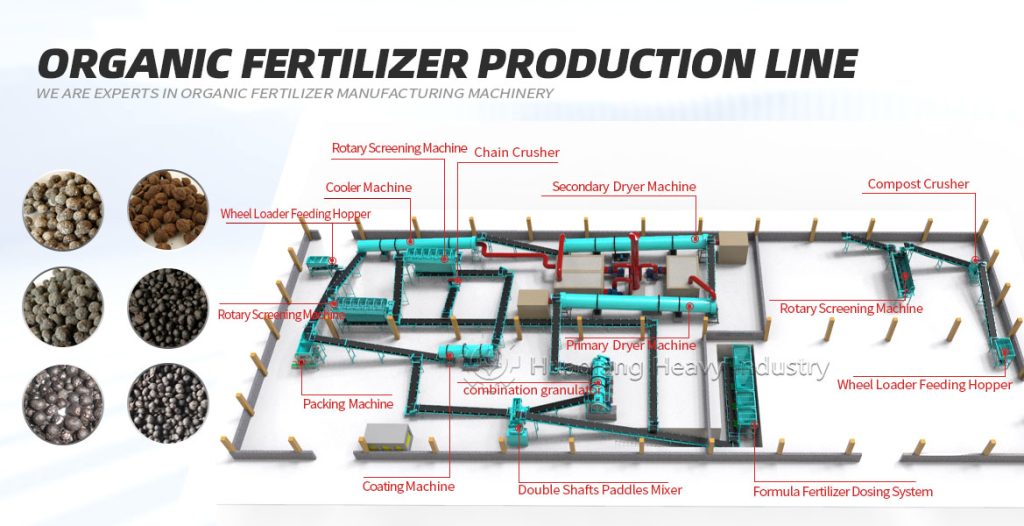

In fertilizer production enterprises, the production line is a complex system composed of a series of equipment such as granulators, crushers, compost turners, and screening machines. Scientific and systematic maintenance is not only the foundation for extending equipment lifespan but also a key means to reduce unplanned downtime and lower overall operating costs. Establishing an efficient and feasible maintenance system has become an important guarantee for fertilizer production enterprises to enhance competitiveness and ensure continuous production.

Core Equipment Maintenance Points and Practical Suggestions As the core equipment in fertilizer production, the granulator’s operating status directly affects product output and quality. For common drum granulators, the wear of the liner plates needs to be closely monitored. Rubber or stainless steel liners, subjected to long-term material friction, will gradually decrease in thickness. When the wear exceeds 3mm, they should be replaced promptly; otherwise, material sticking to the wall and a decrease in pelletizing rate may occur. Maintenance of the transmission system is equally crucial. Gears should be lubricated weekly, and meshing clearance checked monthly to prevent increased equipment vibration due to gear wear. For roller press granulators, it is necessary to regularly clean the material adhering to the roller surface and check the bearing operating temperature quarterly to prevent bearing damage due to overheating.

The key maintenance focus for crushers is on the blades and screens. The chain blades of chain crushers need to be checked for tightness regularly. When the cutting edges are severely worn, they should be sharpened or replaced promptly to ensure uniform material crushing. The screens of semi-wet material crushers should be disassembled and cleaned monthly to prevent material blockage from affecting the output particle size and equipment capacity.

Compost turners are crucial in the organic fertilizer fermentation process. Their hydraulic system and auger blades need to be checked carefully. The hydraulic oil should be changed regularly, and the hydraulic system kept clean. The auger blade bolts should be checked for tightness to prevent loosening and falling off during operation, which could cause equipment damage.

Establishing a systematic maintenance management system is essential. In addition to specific equipment maintenance, establishing a scientific maintenance management system is the systematic foundation for ensuring the long-term stable operation of equipment.

Systematized Daily Inspections: A clear inspection checklist should be established. Before starting the machine each day, check the oil levels at all lubrication points, the tightness of bolts in key areas, and the integrity of safety devices. Clean any residual materials inside the equipment weekly to prevent long-term accumulation of corrosive materials that could damage the equipment.

Standardized Periodic Maintenance: A comprehensive overhaul is recommended monthly to systematically identify potential fault points, such as aging electrical wiring, worn transmission components, and failed seals, thus implementing preventative maintenance.

Professional Personnel Training: Operators and maintenance personnel must undergo systematic training to be familiar with the equipment’s structure, principles, and safe operating procedures, preventing equipment damage caused by improper operation. Strict adherence to procedures is crucial, especially for critical operations such as equipment start-up, shutdown, and load adjustment.

Building a Long-Term Support System: Equipment maintenance is not just about daily operations; a long-term support mechanism is essential. It is recommended that manufacturers establish stable partnerships with equipment suppliers. For example, Zhengzhou Huaqiang Heavy Industry provides lifetime maintenance services and spare parts supply support to its customers. This cooperative model ensures timely technical support in the event of equipment failure.

Furthermore, companies should establish a critical spare parts inventory system. Maintaining adequate inventory of vulnerable parts and critical components (such as liners, cutting tools, and bearings) allows for rapid replacement in case of malfunctions, minimizing downtime losses. Simultaneously, establishing equipment maintenance records documents each maintenance session, including the details of replaced parts and operational status, providing data support for equipment management.

Proactive Maintenance Across the Fertilizer Production Line

The principles of systematic maintenance apply to every piece of equipment within a complete npk fertilizer line or organic production system. This includes upstream fertilizer raw material processing machinery and equipment like crushers and npk blending machine units, which require regular blade and bearing checks. In the core npk fertilizer production process, the granulator demands the most attention. For a disc granulation production line, maintenance focuses on the disc granulator itself, particularly the disc granulator for shaping plate wear and gearbox lubrication.

For an alternative roller press granulator production line centered on a double roller press granulator, maintenance shifts to monitoring roller surface wear, bearing temperatures, and hydraulic system integrity. Similarly, in an organic system fed by a windrow composting machine, the turner’s moving parts require scheduled care. Implementing a rigorous maintenance schedule for this entire suite of professional fertilizer manufacturing equipment—from the npk bulk blending machine to the final granulator—is what ensures high availability, consistent product quality, and protects the substantial capital investment in the production line.

Therefore, maintenance is not a cost center but a strategic function. It directly safeguards production capacity, operational efficiency, and profitability by preventing catastrophic failures and ensuring every component of the integrated manufacturing system performs reliably.

Conclusion: The maintenance of fertilizer production equipment is a systematic project requiring comprehensive implementation by enterprises, from awareness and systems to execution. Refined and standardized equipment management not only extends equipment lifespan and reduces maintenance costs but also ensures production continuity by minimizing unplanned downtime, ultimately improving overall operational efficiency and market competitiveness. In the entire equipment lifecycle management process, a scientific maintenance strategy is a crucial cornerstone for achieving stable production, controllable costs, and safe operation.

.jpg)