In the complex processes of organic fertilizer production, the uniformity of raw material mixing is a crucial factor determining the stability of the final product’s fertilizer efficacy. Traditional mixing processes often face challenges such as material stratification and dead zones in mixing, directly affecting the uniformity of fertilizer nutrient distribution. The double axis mixer, with its unique design principle and superior mixing performance, has become an indispensable core piece of equipment for achieving high-quality production in modern organic fertilizer production lines.

Technological Breakthrough: The Working Principle of Twin-Shaft Reverse Mixing

The core technology of the double axis mixer lies in its unique mechanical structure design. Inside the equipment, two parallel mixing shafts are symmetrically arranged with paddles at a special angle. During operation, two stirring shafts rotate synchronously in opposite directions. Through the special curved surface design of the impellers, the material forms a complex multi-dimensional motion trajectory within the cylinder:

Axial convection: Material flows bidirectionally along the axial direction.

Radial diffusion: Material diffuses outwards under the propulsion of the impellers.

Shear mixing: Relative slippage occurs between different material layers.

Throwing and tumbling: Material is lifted and then falls freely for mixing.

This multi-layered, composite motion mode enables the homogeneous mixing of raw materials with significant differences in phases and properties, such as livestock manure, crushed straw, fermentation agents, and trace element additives, at the molecular level within 3-5 minutes. Actual test data from Huaqiang Heavy Industry Equipment shows that the coefficient of variation for mixing uniformity can be controlled below 3%, a qualitative leap compared to the error rate of over 10% in traditional single-shaft mixers.

Performance Advantages: Three Dimensions Showcasing Professional Strength

High-Efficiency Production Capacity to Meet Large-Scale Needs

Powerful Processing Capacity: Single unit capacity ranges from 1-10 tons/hour, perfectly matching the needs of production lines of different sizes.

Extremely Short Mixing Time: Batch mixing is completed in 3-5 minutes, improving efficiency by over 50% compared to traditional equipment.

Continuous Operation Capability: Combined with automatic batching systems and conveying equipment, it enables 24-hour continuous production.

Case Study: After adopting Huaqiang Heavy Industry’s double axis mixer, a large organic fertilizer company in Indonesia increased its daily production capacity from 150 tons to 200 tons, a 33% increase, through optimized process connections, resulting in annual economic benefits exceeding 3 million yuan.

Wide Raw Material Adaptability, Overcoming Mixing Challenges

Strong Moisture Compatibility: Handles various materials with a moisture content of 20%-55%.

Wide Viscosity Adaptability: Effectively mixes everything from viscous livestock manure to loose straw powder.

High Tolerance for Density Differences: Uniformly mixes organic and inorganic raw materials with significant differences in specific gravity.

The equipment is specifically optimized for addressing a challenge in organic fertilizer production—mixing high-moisture chicken manure with dry auxiliary materials. By adjusting the paddle speed and angle, it ensures ideal mixing results even for viscous materials.

III. Durable and Reliable Design for Long-Term Stable Operation

Strengthened Core Components: The impellers are made of high-chromium wear-resistant alloy steel, with a service life of over 5 years.

Self-Cleaning Function: The uniquely designed impeller shape and polished inner wall of the cylinder effectively prevent material adhesion.

Convenient Maintenance: The bearing housing adopts a double-sealed structure, and the lubrication system is external, making daily maintenance simple and convenient.

Technological Innovation: Intelligent and Precise Control

Modern twin-shaft impeller mixers have achieved intelligent upgrades. Huaqiang Heavy Industry’s latest model possesses the following advanced features:

Precise Frequency Conversion Control:

Impeller speed can be steplessly adjusted within the range of 30-60 rpm.

Optimized mixing parameters according to different raw material characteristics.

Energy Automatic matching of energy consumption to production needs, resulting in significant energy savings.

Automated Control System:

The feed inlet is equipped with an anti-clogging sensor and an automatic unblocking device.

Discharge is precisely controlled by a pneumatic valve, with adjustable discharge time.

Linked with the central control system, it achieves fully automated production.

Optimized Structural Design:

Fully sealed cylinder structure, preventing dust leakage.

No dead corners inside, material residue rate less than 0.3%.

Modular assembly, making installation and maintenance more convenient.

Application Value: Key to enhancing the competitiveness of organic fertilizer products.

Quality Stability Guarantee: Uniform mixing ensures highly consistent nutrient composition in every granule of organic fertilizer, completely solving the problem of uneven fertilizer effectiveness in traditional production methods. This is crucial for meeting the precision fertilization needs of modern agriculture and establishing product brand reputation.

Production Cost Optimization: High-efficiency mixing shortens the production cycle and reduces energy consumption and labor costs. Simultaneously, precise mixing reduces nutrient loss, improves raw material utilization, and reduces overall production costs by 15-20%.

High Process Compatibility

The double axis mixer can seamlessly integrate with various granulation equipment, and is particularly suitable for use with mainstream equipment such as drum granulators and disc granulators to form a highly efficient and complete production line system.

Selection Recommendations: Configuration Scheme Matching Production Needs

For production enterprises of different sizes, the following configuration strategies are recommended:

Small Production Line (1-2t/h):

Select a standard model with a processing capacity of 2-3t/h

Configure a basic control system

Focus on equipment reliability and ease of maintenance

Medium Production Line (3-5t/h):

Select an enhanced model with a processing capacity of 5-6t/h

Configure a frequency converter control system

Add anti-clogging monitoring function

Large Production Line (5t/h and above):

Use multiple machines in parallel or customize large-scale equipment

Configure a fully automatic intelligent control system

Add remote monitoring and fault diagnosis functions

Invest in Quality, Reap Market Benefits

In today’s increasingly competitive organic fertilizer industry, product quality stability has become fundamental for enterprises to survive in the market. As a key piece of equipment ensuring the uniformity of raw material mixing, the investment value of a double axis mixer lies not only in improved production efficiency but also in guaranteed product quality and the establishment of brand reputation.

With years of technological accumulation and rich project experience, Huaqiang Heavy Industry’s double axis mixers have been successfully applied in organic fertilizer production lines in many countries around the world. The equipment has won widespread customer recognition for its superior mixing performance, reliable operation, and attentive after-sales service. For organic fertilizer companies pursuing high-quality production, choosing professional mixing equipment is choosing a sustainable path to quality.

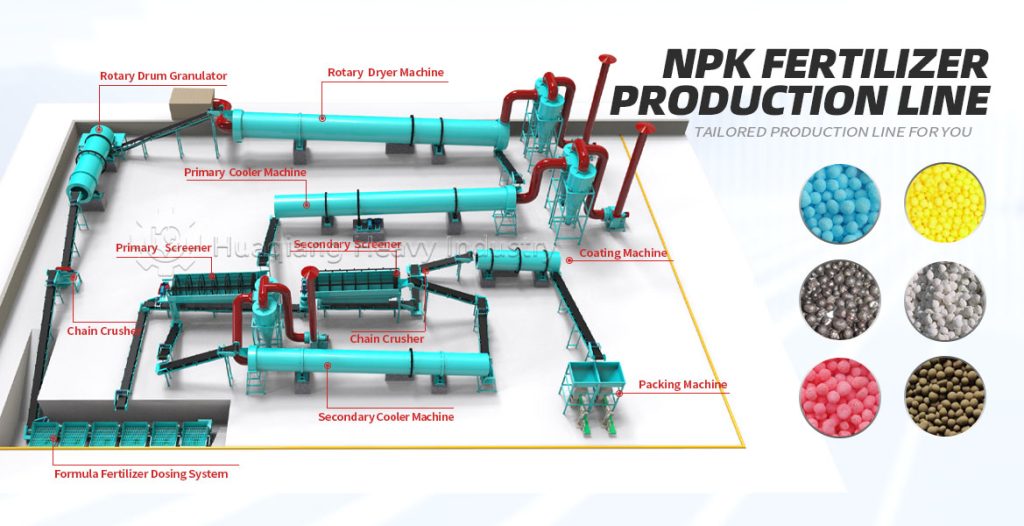

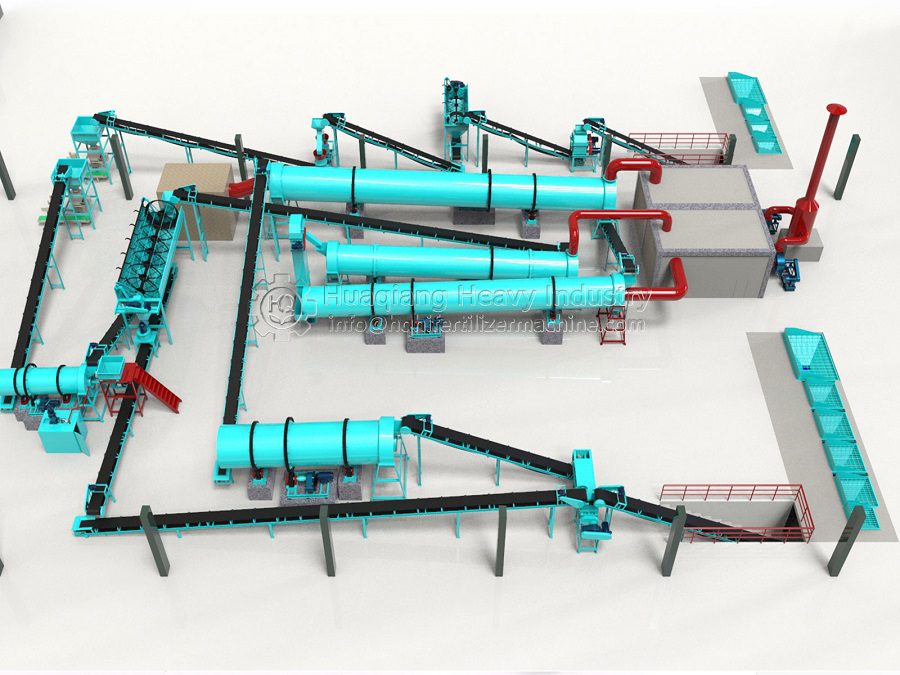

Mixing as a Foundational Process in Fertilizer Manufacturing

The twin-shaft mixer is a critical component within the broader category of fertilizer raw material processing machinery and equipment. Its role in ensuring homogeneity is vital for both NPK and organic production lines. In an organic fertilizer production line, it homogenizes cured compost from a windrow composting machine with various additives before granulation. In an npk fertilizer line, a similar high-shear mixer (or a npk bulk blending machine for pre-granulated materials) is used to uniformly blend powdered raw materials before they are fed to the granulator.

This precise mixing is a prerequisite for successful granulation, regardless of the chosen professional fertilizer manufacturing equipment. For instance, a uniformly mixed powder blend is essential for optimal performance in a roller press granulator production line that uses a double roller press granulator. Similarly, consistent mixing is required for a disc granulator to produce uniform pellets. Therefore, investing in a high-performance mixer is not an isolated decision but a foundational investment that enhances the efficiency and product quality of the entire downstream process, from blending to shaping.

Ultimately, the mixer is the unsung hero that ensures the precise nutrient formula designed by agronomists is physically realized in every batch, enabling both organic and synthetic fertilizer lines to produce consistent, high-quality products that meet market specifications.

In the future, with the continuous improvement of organic fertilizer standards and the increasingly refined agricultural demands, efficient and precise mixing equipment will continue to play an even more important role. Investing in advanced double axis mixers is not only about enhancing production capacity but also a strategic move for the company’s future competitiveness.