In modern fertilizer production, fertilizer compaction machines and flat die pelleting machines are quietly changing the form and future of fertilizers. Unlike chemical reaction equipment, they don’t attract attention, but with their unique mechanical charm, they transform powdered fertilizer into uniform granules.

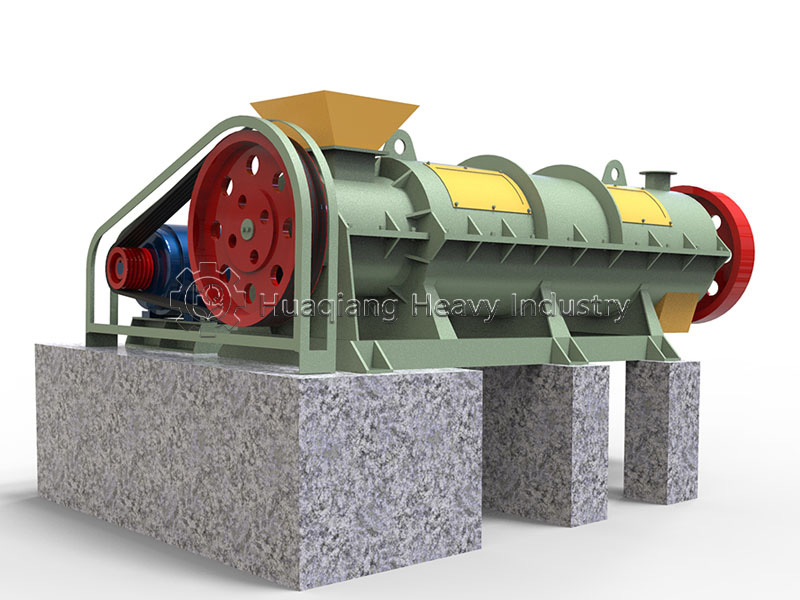

Stepping into the production workshop, you’ll see fertilizer compaction machines working steadily. They use powerful mechanical pressure to “compress” loose powdery raw materials into dense ribbons. This process involves no high temperatures and no binders.

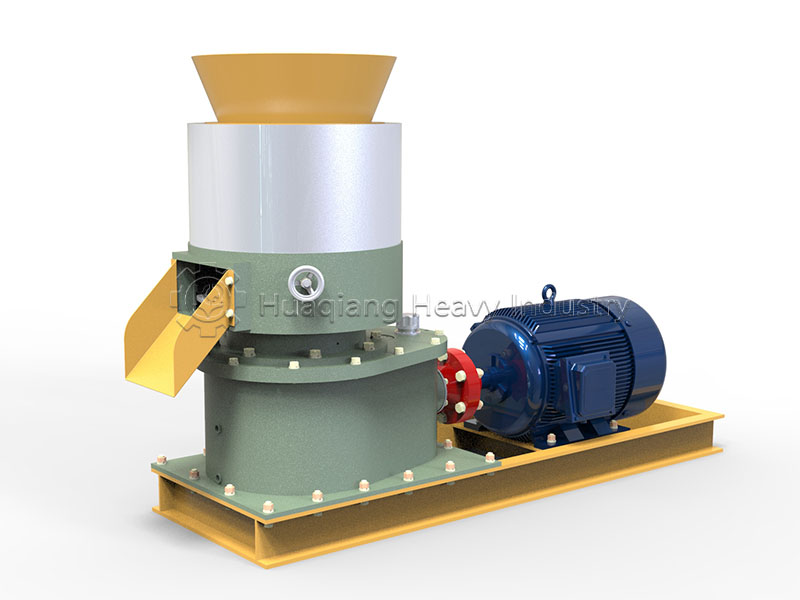

The flat die pelleting machine, on the other hand, showcases another kind of ingenuity. The horizontally placed die acts like a precision sieve; the material, under the pressure of the rollers, passes through the holes in the die, instantly becoming uniformly sized granules.

The combination of these two devices creates surprising possibilities. Powdered fertilizers that are prone to clumping become more fluid, easier to store and apply. Active ingredients are firmly locked inside the granules, reducing drift loss during use and making nutrient release more controllable.

More importantly, this physical granulation method has opened new doors for the development of specialty fertilizers. Whether it’s a compound fertilizer requiring the addition of trace elements or a special fertilizer for specific crops, it can all be achieved by adjusting the mold and process parameters. On the path to sustainable agricultural development, equipment like fertilizer compaction machines and flat die pelleting machines are playing a unique role.