Agriculture is always the top priority, and only by developing agriculture well can we have more confidence to develop other technologies. Therefore, our country’s agricultural policies are also quite good. However, due to years of excessive use of fertilizers, the problem of soil compaction is becoming increasingly serious, which is why there is a strong support for organic fertilizers. Organic fertilizer equipment is specialized in producing organic fertilizers, Organic fertilizers are also very effective in solving the problem of soil compaction and increasing soil organic matter, so it can be seen that the development of organic fertilizers in the future is very good. To achieve circular and safe development in agriculture, it is necessary to use more organic fertilizers to increase the content of soil organic matter.

Organic fertilizer fermentation equipment is a production line composed of multiple equipment links, and the higher the output, the larger the equipment model. The price of different configurations is naturally higher than that of small output. A set of organic fertilizer fermentation equipment is not a fixed set of equipment, but needs to be determined based on the on-site site and materials. For example, chicken manure has a high amount of moisture, and during fermentation, the moisture must be reduced. Corn cobs that are crushed with straw can be added, otherwise they cannot be made into particles; Sheep manure is relatively dry, and when fermenting, it can be directly granulated without the need for adding straw or other materials. The equipment used varies depending on the process.

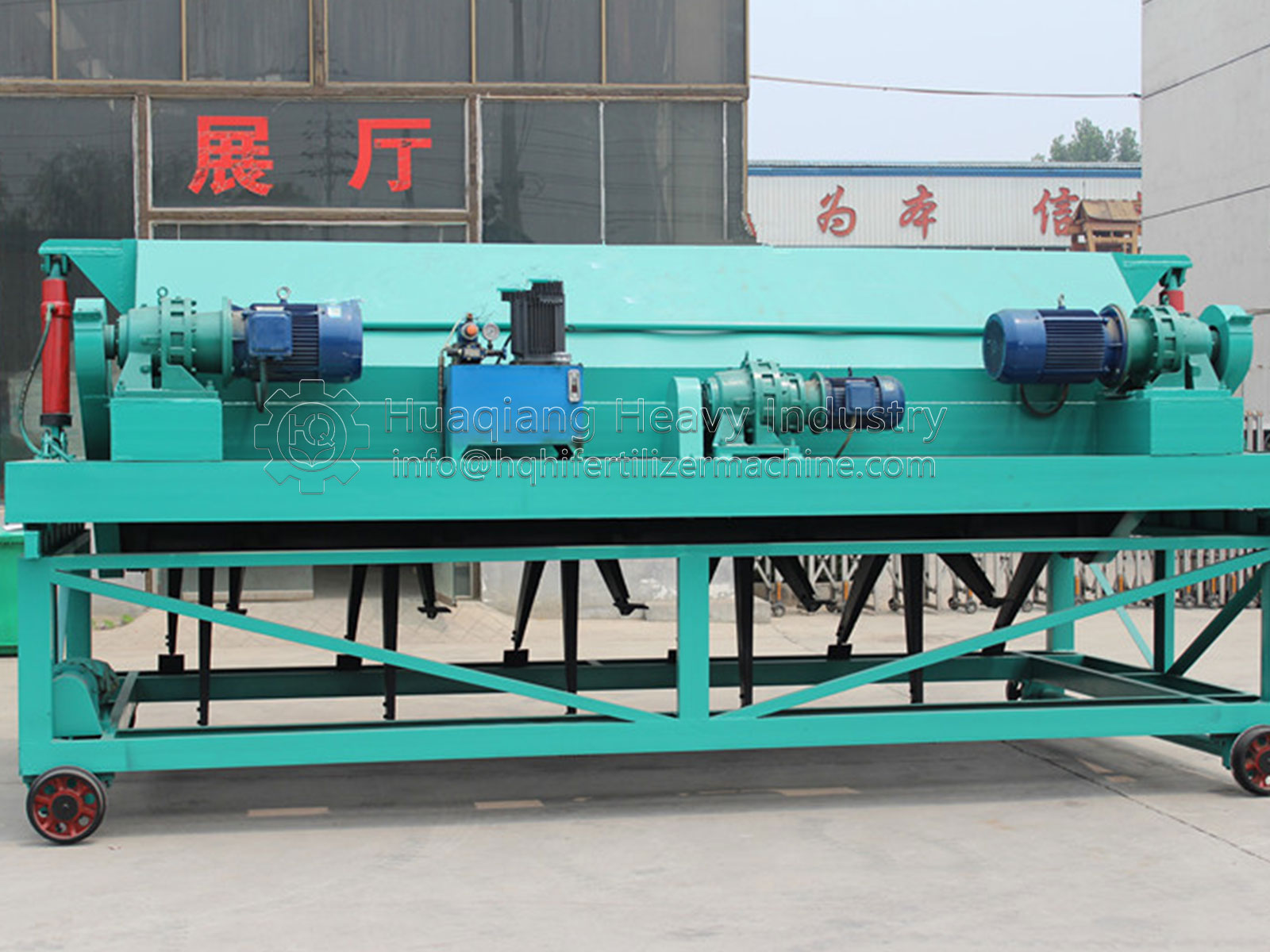

Special functions of organic fertilizer composting machine:

1. The control cabinet is centrally controlled and can achieve manual or automatic control functions.

2. Equipped with a soft starter, low impact load during startup.

3. Equipped with a gear shifting hydraulic lifting system.

4. The gear teeth are sturdy and durable, with certain crushing and mixing functions for materials.

5. The limit travel switch plays a safety and limit role.

The organic fertilizer composting machine is suitable for aerobic fermentation and can be used in conjunction with solar fermentation chambers, fermentation tanks, and transfer machines. When used in conjunction with transfer machines, it can achieve the function of multiple tanks in one machine. The fermentation tanks it is equipped with can continuously discharge or batch discharge, with high efficiency, stable operation, durability, and even flipping.