In the wave of organic waste resource utilization, the trough type compost turner acts like a master fermentation expert, transforming organic materials such as livestock manure and crop straw into high-quality organic fertilizer through precise mechanical design and intelligent control systems. This equipment not only accelerates the natural fermentation process but also makes waste treatment efficient and environmentally friendly.

Precision Structure: Perfect Coordination of Five Systems

Intelligent Travel System

Composed of precision transmission systems including motors, reducers, and travel wheels, ensuring smooth equipment movement within fermentation tanks. The intelligent control system precisely controls travel speed for uniform turning operations.

Efficient Turning Mechanism

Utilizing specially designed blades or spiral blades that penetrate deep into materials for thorough turning. Unique blade angles and arrangements ensure complete material mixing and even oxygen distribution.

Precise Lifting Device

Hydraulic or mechanical lifting systems intelligently adjust turning height according to material depth, ensuring optimal turning depth with each operation and improving fermentation efficiency.

Smart Oxygen Supply System

Equipped with efficient fans and pipeline networks, providing continuous and stable oxygen supply to fermentation tanks. Smart sensors monitor oxygen concentration in real-time, automatically adjusting oxygen supply.

Wide Applications: Environmental Solution Across Multiple Fields

Organic Fertilizer Production

Transforms livestock manure and agricultural waste into high-quality organic fertilizer, achieving resource recycling

Bioenergy

Processes organic waste like kitchen waste to produce biomass energy raw materials

Environmental Treatment

Handles municipal sludge and industrial organic waste, reducing environmental pollution

Agricultural Recycling

Promotes agricultural waste resource utilization, driving sustainable agricultural development

Particularly noteworthy is the PLC intelligent control system of the trough turner, which monitors key parameters such as temperature, humidity, and oxygen concentration during the fermentation process in real-time. When abnormalities are detected, the system automatically adjusts turning frequency and oxygen supply to ensure the fermentation process remains in optimal condition. This intelligent management approach ensures more stable and reliable organic fertilizer quality.

Process Advantages: Redefining Fermentation Efficiency

Compared to traditional composting methods, the trough turner reduces the fermentation cycle from several months to 15-20 days, improving efficiency by over 50%. Its enclosed fermentation tank design effectively controls odor diffusion and reduces environmental pollution. Meanwhile, automated operation significantly reduces labor costs, making organic fertilizer production more economically viable. The safety protection system, including limit switches and emergency stop buttons, ensures equipment operational safety.

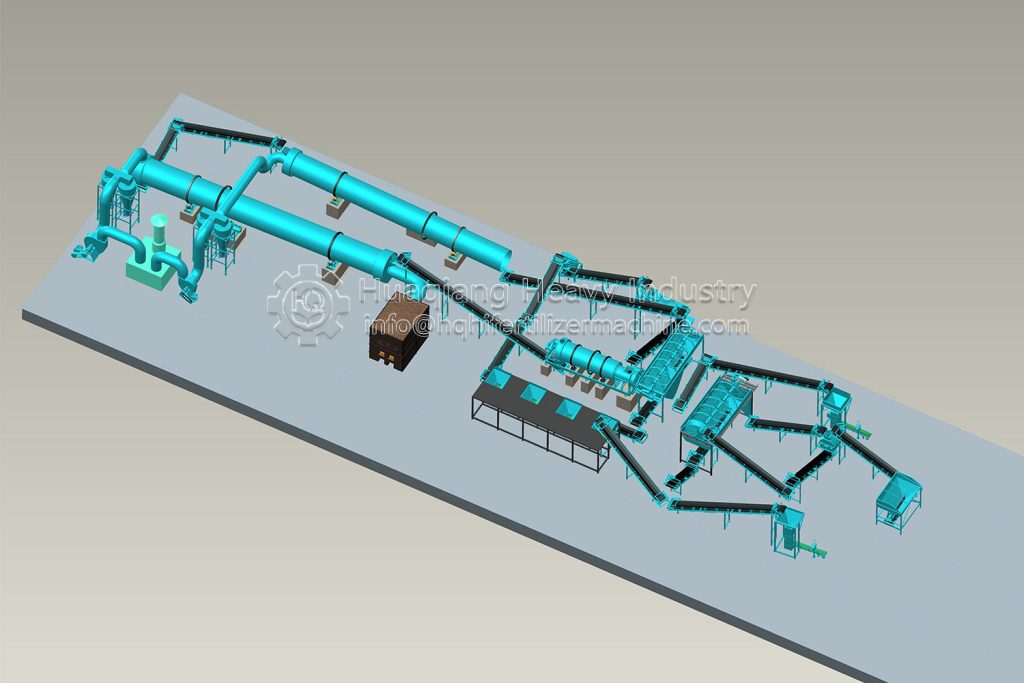

The trough compost turning machine represents a pinnacle achievement in sustainable technology, serving as the cornerstone equipment in the organic fertilizer production line. This sophisticated fertilizer production machine excels in optimizing the organic fertilizer fermentation process through its precision travel system and intelligent oxygen control mechanisms. As a vital component among equipments required for biofertilizer production, it efficiently transforms organic waste into valuable resources, driving circular economy development while supporting greener agricultural practices.

During the crucial organic fertilizer fermentation phase, the trough-type turning machine demonstrates exceptional performance by maintaining optimal temperature and aeration conditions. This compost fertilizer machine continuously mixes and aerates organic materials, significantly accelerating decomposition while eliminating pathogens. The machine’s robust design and efficient turning mechanism ensure consistent quality throughout the bio organic fertilizer production line, making it indispensable for modern organic waste management and resource utilization.

Integrated within comprehensive organic fertilizer production systems, these advanced turning machines provide fundamental technical support for sustainable agriculture. Their operational excellence not only enhances the efficiency of bio organic fertilizer production but also promotes environmental protection by converting waste into nutrient-rich fertilizers. As global focus on sustainability intensifies, these machines continue to push the boundaries of organic fertilizer fermentation technology, enabling more efficient and eco-friendly production methodologies across the agricultural sector.