Core Value of Windrow Composting

Windrow composting, also known as window composting, is a traditional method of organic waste decomposition through natural ventilation and regular turning. This composting approach not only transforms agricultural waste, livestock manure, and kitchen waste into high-quality organic fertilizer rich in humus, but also generates high temperatures during the fermentation process that effectively eliminate pathogens and weed seeds.

The final product of windrow composting can significantly improve soil structure, enhance water retention and aeration, and reduce dependence on chemical fertilizers. This method of recycling organic waste provides important support for sustainable agricultural development.

Limitations of Windrow Composting

Although windrow composting offers advantages of simple operation and low investment costs, it also has some obvious limitations. This method requires relatively large, flat land areas and is susceptible to weather conditions.

During rainy seasons, the piles are prone to waterlogging, leading to anaerobic fermentation and odor production. In dry seasons, frequent watering is necessary to prevent the piles from becoming too dry. Additionally, uneven natural ventilation often results in the outer layers of the pile maturing while the inner portions remain incompletely fermented.

Windrow composting typically requires a fermentation period of 2-3 months, which is longer compared to other composting methods. Open-air storage can also lead to nitrogen loss through volatilization or leaching, affecting the final product’s fertilizer efficiency.

Selecting Appropriate Turning Tools

Choosing the right turning tools according to the composting scale is crucial. For home gardens and small composting projects, manual tools like three-prong rakes and wide-head shovels are both flexible and practical. For reduced labor intensity, small push-type compost turners are a good choice.

For small to medium-sized farms, gasoline or electric-powered compost turners can significantly improve work efficiency, with turning depths reaching 50-80 cm and efficiency five times higher than manual labor. Large composting sites require professional windrow turners that not only have large processing capacities but also effectively break up clumps to ensure compost quality.

Key Techniques for Windrow Construction

Site Selection and Preparation

Choose sites with higher elevation and good drainage, with a base layer of gravel or straw as insulation, which both prevents water accumulation and reduces nutrient loss.

Material Ratio Control

Maintain a carbon to nitrogen ratio between 25-30:1, with carbon materials (such as straw, leaves) accounting for 70%-80% and nitrogen materials (such as manure, kitchen waste) accounting for 20%-30%. Proper ratio is the foundation for efficient fermentation.

Pile Dimension Management

Ideal piles should be trapezoidal or rectangular in shape, 2-3 meters wide, 1.2-1.5 meters high, with length adjusted according to the site but not exceeding 20 meters. These dimensions ensure proper ventilation while preventing excessive water loss.

Moisture and Aeration Control

Material moisture content should be maintained between 55%-60%. Internal ventilation can be enhanced by inserting ventilation pipes or corn stalk bundles into the pile. Appropriate covering materials can prevent rainwater erosion and nutrient volatilization.

Optimization Recommendations

To improve the efficiency and quality of windrow composting, regularly monitor pile temperature and turn the pile promptly when temperatures exceed 65°C. Simultaneously, observe changes in pile odor – foul odors indicate insufficient ventilation and require increased turning frequency.

Through scientific management and appropriate tool selection, windrow composting can become an effective method for processing organic waste and producing high-quality organic fertilizer, contributing to ecological agriculture and sustainable development.

Advanced Composting Technology Integration

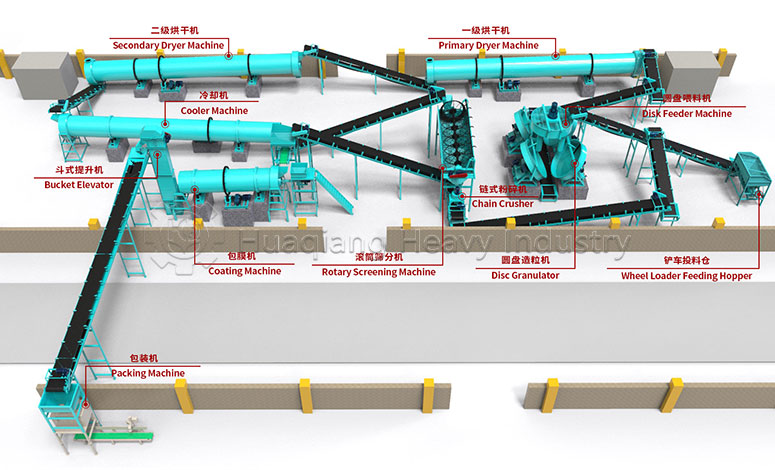

To optimize the organic fertilizer fermentation process, modern composting operations increasingly integrate specialized fertilizer production machine systems. The selection between a large wheel compost turner for extensive windrows or a chain compost turner for heavier materials represents crucial decisions in configuring the complete organic fertilizer production line. Advanced fermentation composting technology for organic fertilizer utilizes these windrow compost turning machine options to create optimal aerobic conditions, significantly enhancing decomposition efficiency. For operations targeting premium products, upgrading to a bio organic fertilizer production line requires additional equipments required for biofertilizer production such as precise temperature monitors and microbial inoculation systems. Each compost fertilizer machine must be strategically selected to match operational scale and product specifications, ensuring the transformation of raw organic materials into high-value fertilizers through scientifically managed decomposition pathways.

.jpg)