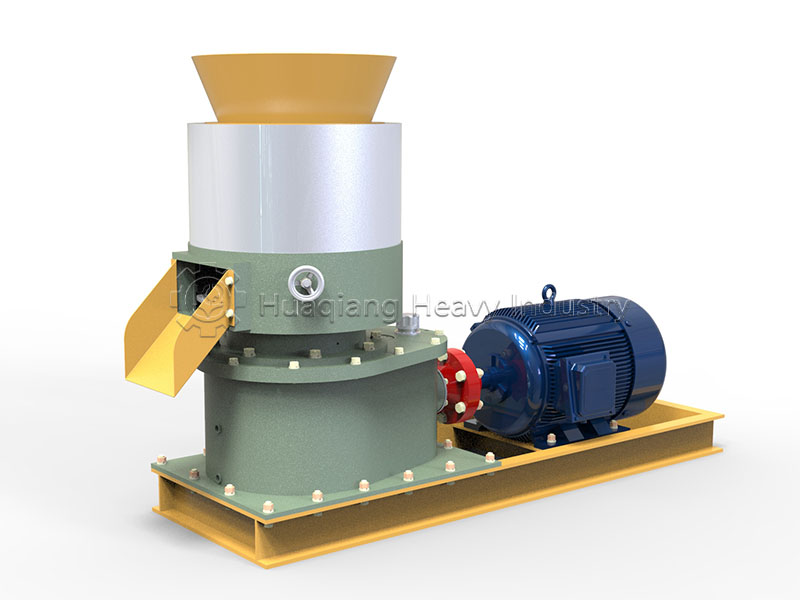

Small and medium-sized organic fertilizer companies are characterized by moderate production capacity, diverse raw materials, and large batch sizes. The design features of the flat die pelleting machine perfectly meet these needs, making it a cost-effective choice for these companies.

1.Low Equipment Investment Cost

The flat die pelleting machine has a relatively simple structure and does not require a complex transmission system. The purchase cost of a single unit is only 60%-70% of that of similar granulator equipment with similar production capacity. Furthermore, installation does not require a complex foundation, saving small and medium-sized companies from the high initial investment.

2.Flexible Raw Material Adaptability

Small and medium-sized organic fertilizer companies often purchase local raw materials, which can have large fluctuations in moisture and fiber content. The flat die granulator’s wide adaptability allows it to handle high-fiber straw materials, and the vertical compression of the rollers prevents tangling. For fermented materials with slightly higher moisture content, the flat die surface is easy to clean and prevents sticking.

3.Convenient Production Changeover

Small and medium-sized companies often produce a variety of products in small batches, requiring frequent adjustments to pellet size. It only takes 1-2 people to replace the flat die of the flat die pelleting machine, and it can be completed within 30 minutes. In addition, the cost of flat dies with different apertures is low. The company can reserve multiple sets of flat dies and quickly switch product specifications to meet the needs of different customer orders.