The roller press granulator production line is specially designed for compound fertilizer production. With its core advantages of precise proportioning and efficient granulation, it has become an ideal choice for balancing nutrients and improving fertilizer efficiency, injecting strong momentum into the company.

Its core competitiveness lies in its precise control of compound nutrients. The automatic batching system precisely blends nitrogen, phosphorus, potassium, and trace elements according to crop needs. The double axis mixer quickly blends the raw materials, preventing uneven nutrient distribution and laying a foundation for high-quality granulation.

The granulation process offers unique advantages. The double roller press granulator uses counter-rotating high-strength rollers to squeeze the material into thin flakes, which are then crushed and screened to form uniform granules. No binders are required, and the purely physical action preserves nutrient activity. The granules are high in hardness and have a controllable dissolution rate, meeting the needs of different soils and crops, thereby improving fertilizer utilization.

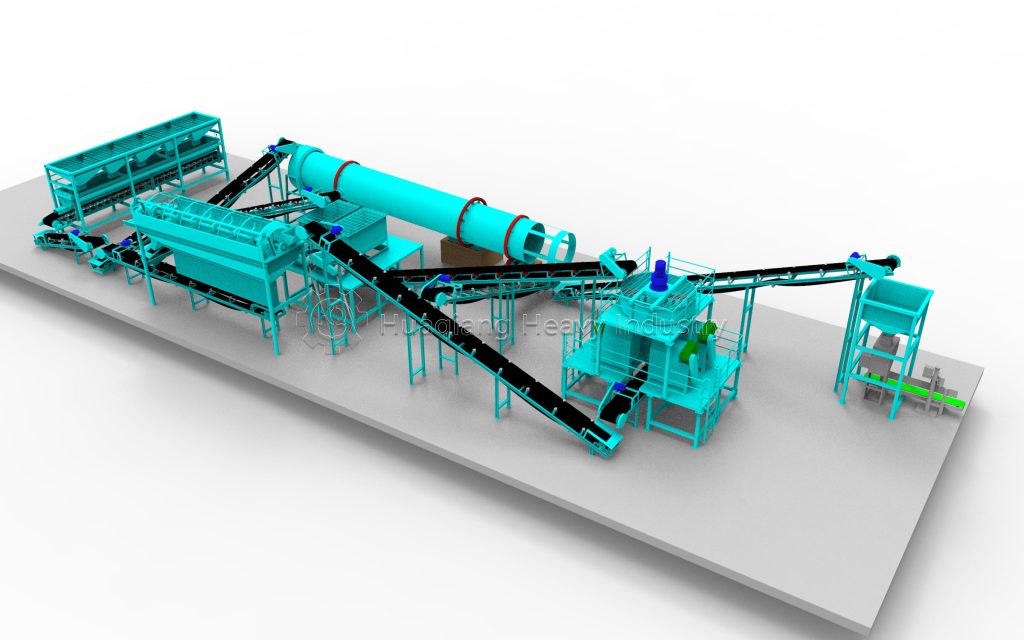

The production line features a compact, efficient, and adaptable process. From raw material proportioning and mixing to granulation and screening, each step is seamlessly integrated, forming a continuous closed loop. For high-concentration, slow-release, and controlled-release compound fertilizers, granule specifications can be adjusted by adjusting the roller pressure and speed to meet diverse needs. A return system returns unqualified granules back to the production line, improving raw material utilization and reducing production costs.

The equipment offers outstanding stability and environmental friendliness. The rollers are made of a wear-resistant alloy and undergo a special heat treatment for corrosion resistance, resulting in a long service life and minimal maintenance. Production is wastewater-free, and dust is collected and treated for discharge, meeting environmental standards. The intelligent control system enables visual parameter adjustment, and one-button start and stop operations reduce operational barriers, making large-scale production easy for even small and medium-sized enterprises.

As the compound fertilizer market pursues precise nutrient delivery and efficient application, the roller press granulator production line, with its stable quality, flexible production, and cost-effectiveness, has become a key piece of equipment for enhancing companies’ competitiveness, helping compound fertilizers realize greater value in modern agriculture.