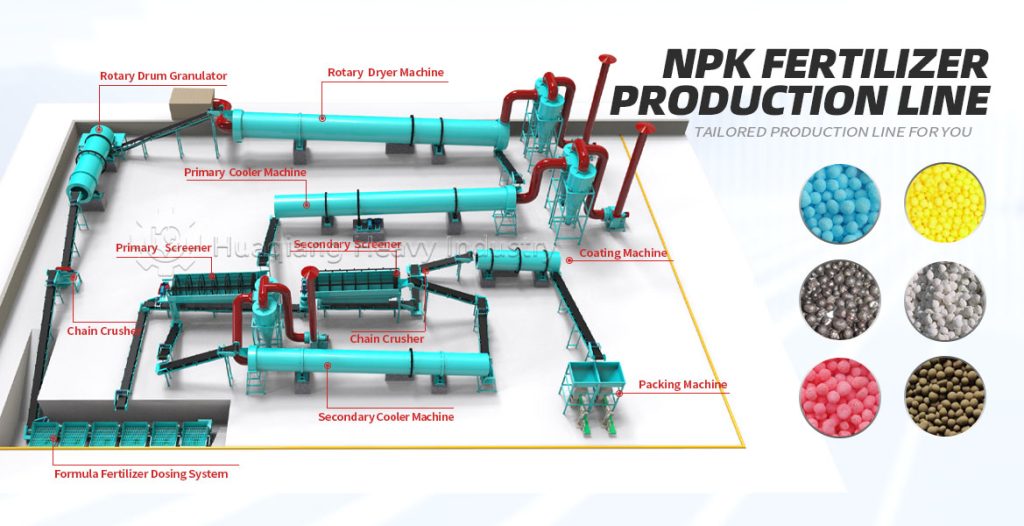

Potassium is an essential macronutrient for crops. High-potassium fertilizer, as an important category of NPK fertilizers, is processed and shaped using NPK fertilizer production lines equipped with rotary drum granulators and other equipment. It not only precisely supplements nutrients but also strengthens the foundation for high yields by regulating crop physiological metabolism and enhancing stress resistance. It is suitable for crops with high potassium requirements, ensuring both increased yield and improved quality.

High-potassium fertilizer contributes to high yields through multiple mechanisms. Firstly, it enhances stress resistance, regulating cell osmotic pressure to improve drought and cold resistance, and strengthening stem toughness to prevent lodging; secondly, it promotes nutrient transport, acting as an enzyme activator to accelerate the transport of photosynthetic products to harvest organs, increasing fruit setting rate; thirdly, it improves fruit development, reducing flower and fruit drop and malformed fruits, and increasing the rate of marketable fruits.

Different crops have varying potassium requirements, making targeted application more efficient. Economic crops such as tomatoes and cucumbers require a significant increase in potassium during the fruit expansion stage; high-potassium fertilizer can promote fruit expansion and increase sugar content. For field crops such as corn and rice, application during the jointing and grain filling stages enhances lodging resistance and increases thousand-grain weight. For fruit trees, application during the fruit expansion stage reduces fruit cracking and extends shelf life.

Scientific application and high-quality production are indispensable. The production line can precisely control the proportion of high-potassium fertilizer, and the double roller press granulator is suitable for cold pressing and molding requirements, ensuring granule quality. During application, it is necessary to control the amount to prevent nutrient antagonism, apply in stages during key periods, and combine with organic fertilizers to improve the conversion efficiency of potassium elements, achieving synergistic effects.

In summary, producing high-potassium fertilizer using professional equipment and applying it scientifically based on crop characteristics and soil conditions can achieve both increased yield and improved quality.