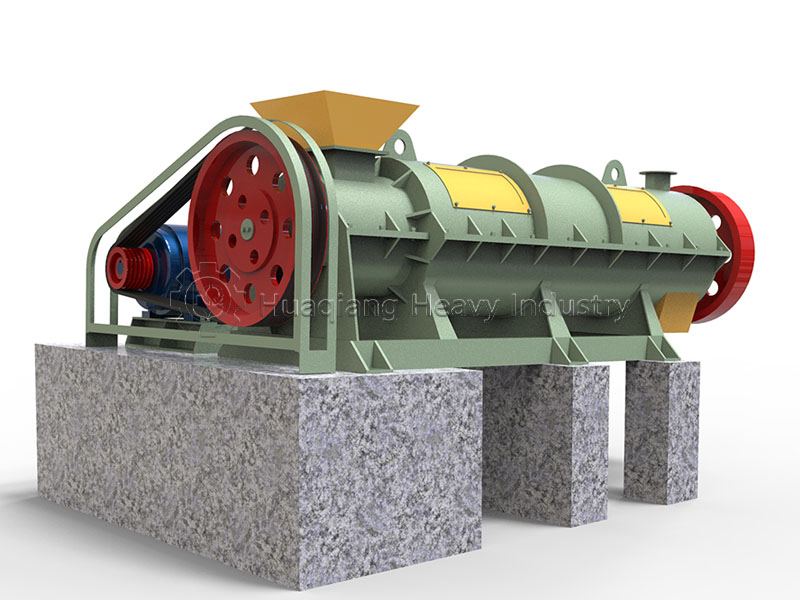

In fertilizer granulation production, the ring die granulator is a key piece of equipment for achieving “powdered raw materials → uniform granules.” It is particularly suitable for a variety of fertilizer types, including organic fertilizers, compound fertilizers, and biofertilizers. The key to its granule formation lies in the synergistic effect of the “ring die + press roller” system, as well as precise adaptation to the raw material characteristics.

The core working components of the ring die granulator are a ring die with densely packed holes (ring die) and two to three press rollers within it. When the machine is started, pre-treated (mixed and conditioned) fertilizer raw materials (usually with a moisture content of 15%-25%) are fed into the extrusion chamber between the ring die and the press rollers. The motor drives the ring die at high speed, while the press rollers follow in the opposite direction. Friction forces press the raw materials tightly against the inner wall of the ring die.

As the ring die continues to rotate, the raw materials are forcibly squeezed into the small holes of the ring die, where they undergo a process of “extrusion → shaping → solidification.” The shape of the small holes (circular, cylindrical, or oblate) determines the appearance of the pellets, while the length-to-diameter ratio of the holes (also known as the “compression ratio”) influences pellet hardness.

Finally, the formed pellets are cut by a scraper on the outside of the ring die, forming uniform fertilizer granules. The entire process achieves “continuous feeding and continuous granulation,” adapting to the mass production needs of organic fertilizer production lines.