In an NPK fertilizer production line, the proportioning process is the key step in determining fertilizer quality and effectiveness. By precisely controlling the ratios of nitrogen (N), phosphorus (P), potassium (K), and trace elements, it adapts fertilizer to the needs of different crops, soils, and growth stages, directly impacting agricultural production yield and quality.

The proportioning process must adhere to the principle of “customization on demand.” Nutrient requirements vary significantly among crops: rice requires high nitrogen to promote tillering, so the nitrogen content in the proportion is often 20%-25%; fruit trees require high potassium to enhance sweetness during the fruit-bearing stage, so the potassium ratio should be adjusted to 15%-20%; vegetables require a balanced ratio of nitrogen, phosphorus, and potassium, typically maintaining a ratio of approximately 1:1:1. Soil conditions also influence the proportioning process. Acidic soils require reduced phosphorus application to prevent fixation, while saline-alkali soils require increased nitrogen to compensate for leaching losses.

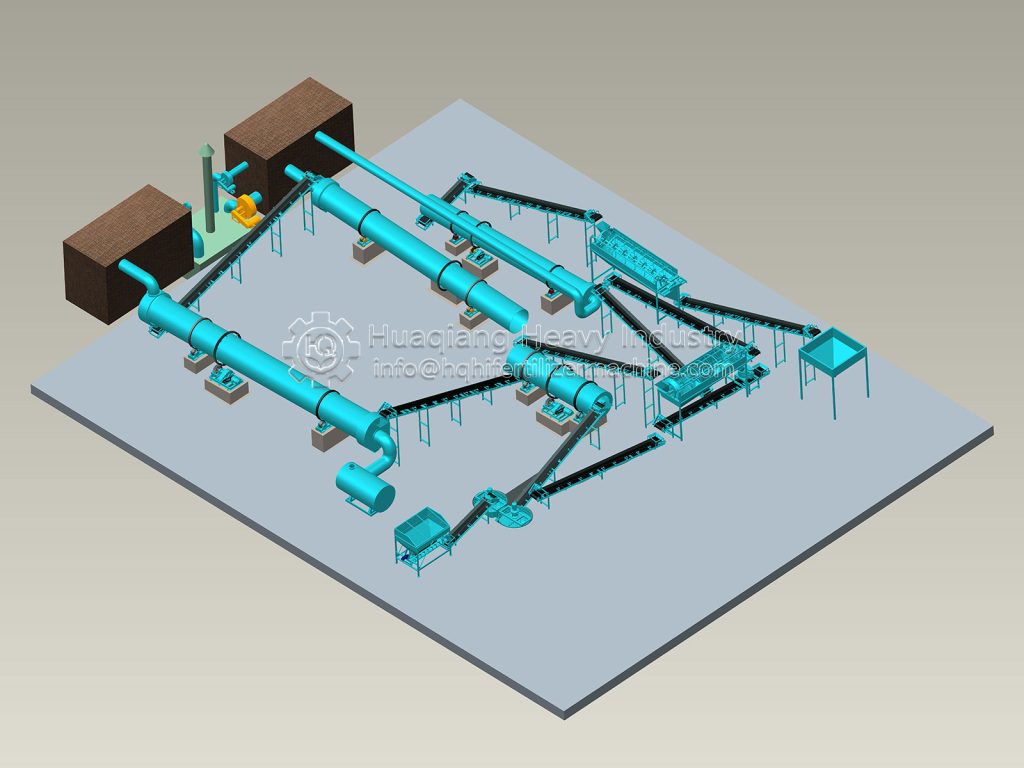

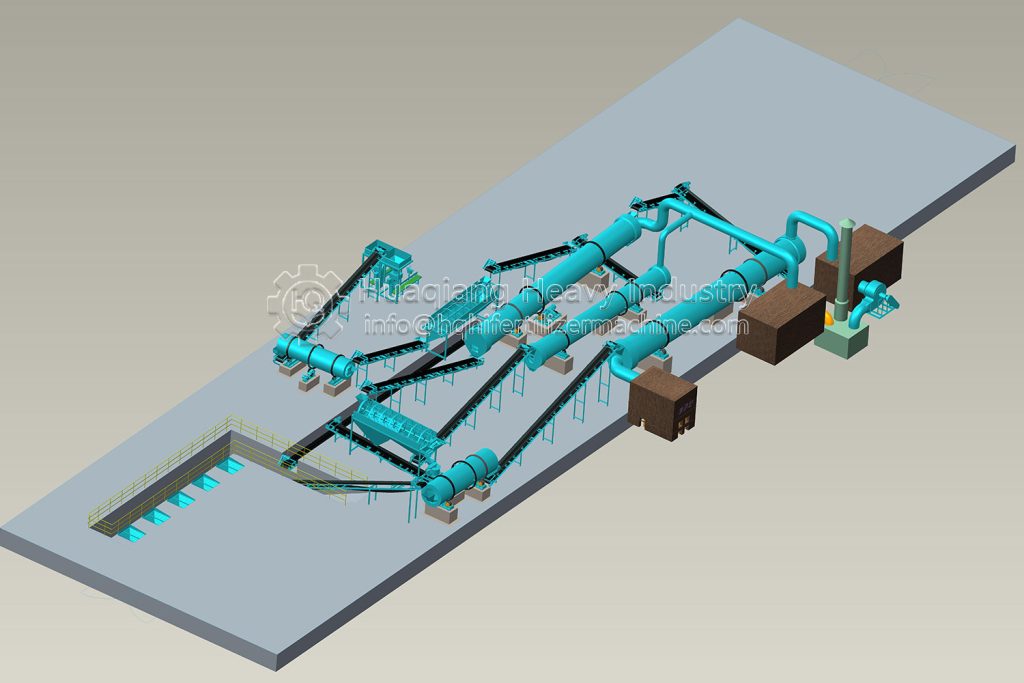

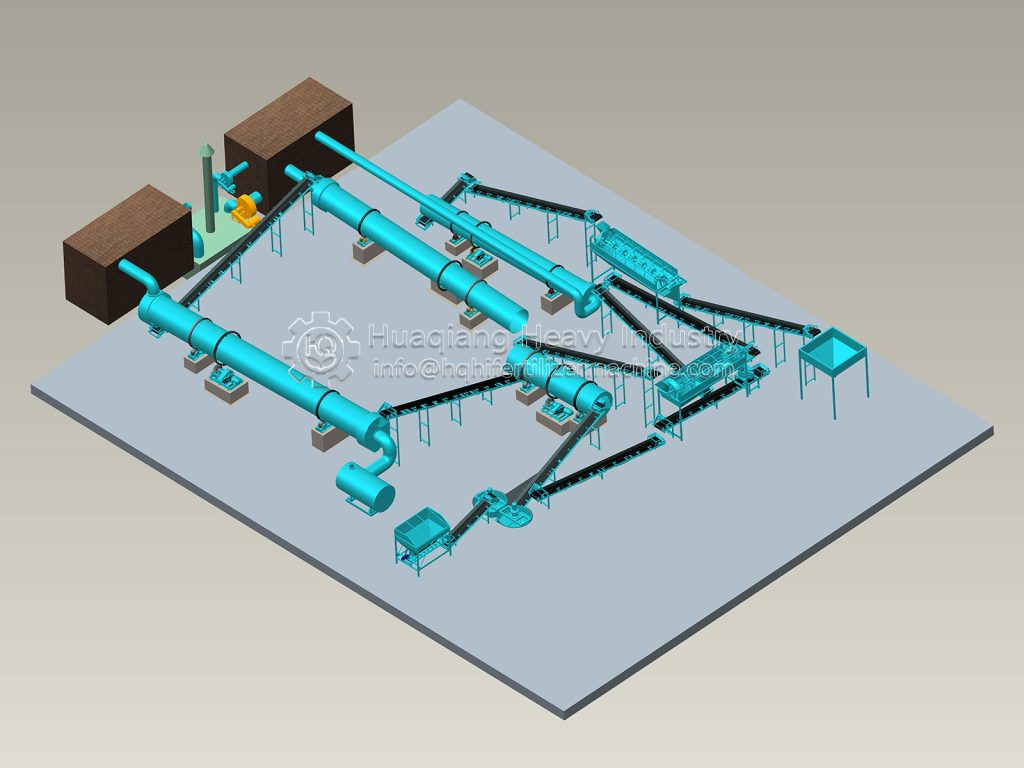

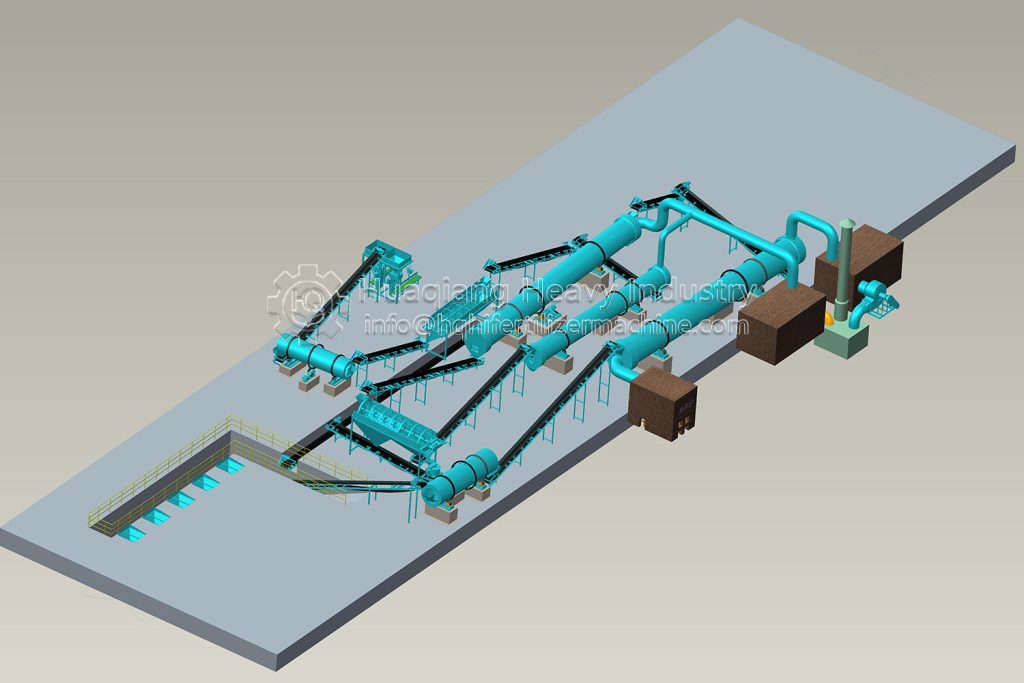

Precise proportioning relies on advanced technology. Modern production lines often utilize “automatic batching systems.” Sensors monitor the moisture and particle size of raw materials in real time, and combined with a PLC control system, they automatically adjust the feed rate with an error controllable within ±0.5%. For example, for wheat fertilizer, the system automatically delivers urea, monoammonium phosphate, and potassium chloride to the mixer in the corresponding proportions according to an “18-12-15” formula, ensuring consistent nutrient content in each batch.

The batching process must also balance environmental protection and efficiency. Improper batching can lead to nutrient waste: excessive nitrogen content can easily lead to eutrophication, while excessive phosphorus can cause soil compaction. Therefore, production lines incorporate “nutrient balance algorithms” to optimize the batch based on regional soil testing data, minimizing nutrient loss while meeting crop needs. Furthermore, pre-mixing disperses insoluble raw materials, preventing localized nutrient excess or deficiency caused by uneven batching.

As the core link of the NPK fertilizer production line, scientific ratio is not only the key to improving fertilizer competitiveness, but also an important guarantee for helping agriculture “reduce weight and increase efficiency” and achieve green production.