Compound fertilizers come in a wide variety of types. The production of high-quality compound fertilizers largely relies on NPK fertilizer production lines, processed using core NPK fertilizer production equipment such as NPK fertilizer granulators. The core classification logic revolves around “nutrient ratio” and “functional suitability.” Different types differ significantly in nutrient composition and fertilizer efficacy characteristics, making them suitable for different crops and planting scenarios.

Based on the nitrogen, phosphorus, and potassium nutrient ratio, they can be divided into balanced and specialized types. Balanced types, such as 15-15-15 compound fertilizer, have equal amounts of nitrogen, phosphorus, and potassium, making them suitable for the entire growth period of field crops such as wheat and corn, and offering strong versatility; specialized types have targeted ratios, such as high-nitrogen types (25-10-10) suitable for leafy vegetables to meet the needs of branch and leaf growth; high-potassium types (15-10-25) suitable for the fruit expansion stage of fruits and vegetables to improve fruit sweetness and quality; and high-phosphorus types (10-25-10) suitable for the seedling stage of crops to promote root development.

Based on functional orientation, they can be divided into conventional compound fertilizers and functional compound fertilizers. Conventional compound fertilizers only provide basic nutrients to meet the basic growth needs of crops; functional compound fertilizers additionally contain humic acid, amino acids, trace elements, or beneficial microorganisms, and have functions such as soil improvement, stress resistance, and disease resistance.

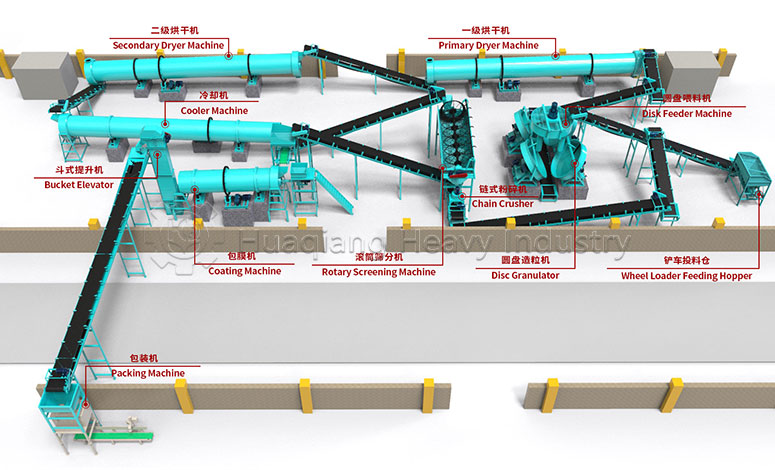

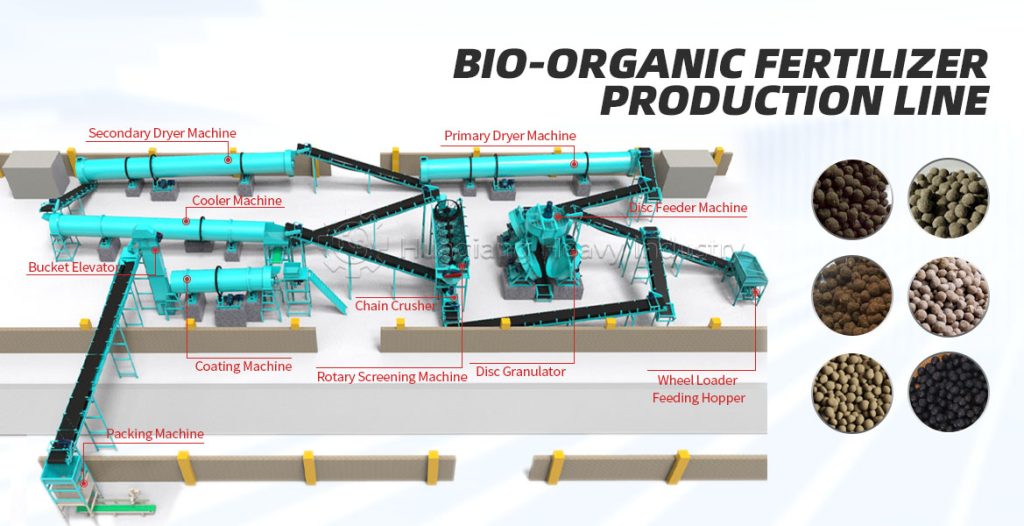

Based on form, there are granular and powdered compound fertilizers. Granular compound fertilizers are processed and shaped by NPK fertilizer granulators, offering stable fertilizer release and convenient storage and transportation, making them suitable for large-scale mechanized planting; powdered fertilizers dissolve quickly and are fast-acting, suitable for small-scale planting or stages where crops urgently need fertilization.