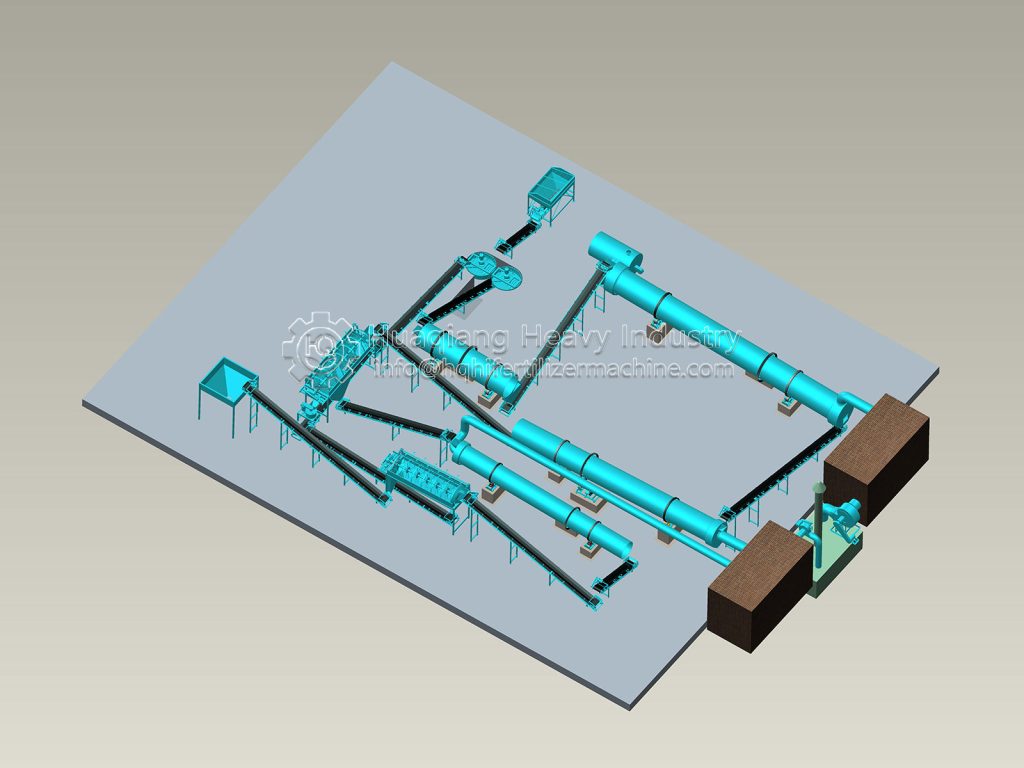

The NPK fertilizer production line, centered around the NPK fertilizer granulator, is a core support for the fertilizer industry. With its key role in increasing compound fertilizer production capacity, optimizing quality, and adapting to large-scale farming, it has become a crucial force in driving the high-quality development of the agricultural economy.

The NPK fertilizer production line ensures stable agricultural production. The efficient production line achieves precise nutrient ratios and automated processes. By controlling granule quality through the core NPK fertilizer granulator, it can quickly produce specialized compound fertilizers tailored to different crops and soils, significantly improving production capacity and quality stability.

The popularization of NPK fertilizer production lines and fertilizer granulators drives the upgrading of upstream raw material processing and machinery manufacturing, and fosters downstream industries such as large-scale farming and agricultural product processing. The efficient operation of the equipment reduces production and planting costs, increasing farmers’ income and agricultural efficiency.

Intelligent and energy-efficient NPK fertilizer production lines are adapted to the needs of modern large-scale and mechanized farming, promoting the deep integration of the fertilizer industry with digital agriculture and ecological agriculture. Precise fertilization reduces resource waste, enhances the resilience of agriculture, and achieves a win-win situation for both economic and ecological benefits.