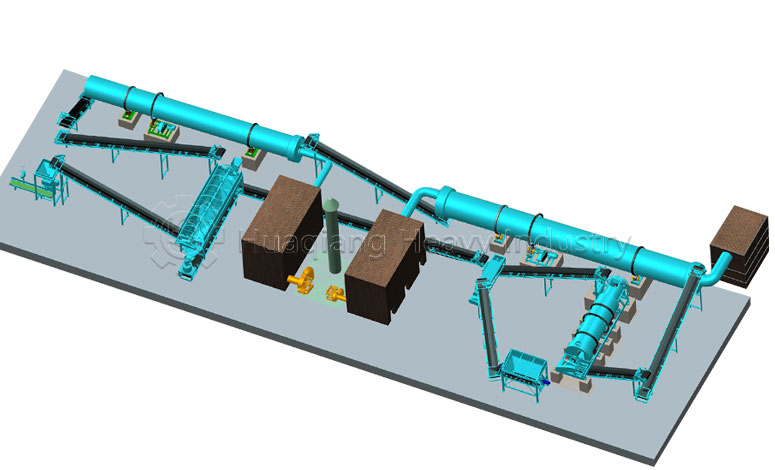

Roller press granulator production lines, with their advantages of cold pressing, energy efficiency, and wide compatibility with raw materials, are widely used in the processing of compound fertilizers and organic fertilizers. They eliminate the need for high-temperature drying, maximizing the retention of raw material activity and nutrients.

Raw Material Pretreatment: First, the raw materials are precisely proportioned according to a preset ratio. Inorganic raw materials such as urea and monoammonium phosphate, or well-rotted organic materials, are mixed with auxiliary materials and fed into a fertilizer mixer for homogenization, ensuring uniform nutrient distribution. Then, the material is processed by crushing and screening equipment to achieve a particle size of 80 mesh or higher, while simultaneously adjusting the moisture content to 8%-12% to avoid clumping or poor forming.

Roller Pressing: The pretreated material is fed into a double roller press granulator. High pressure is applied by a pair of counter-rotating rollers, pressing the loose material into dense flakes or blocks. The roller pressure needs to be finely adjusted according to the material characteristics. Insufficient pressure will result in brittle particles, while excessive pressure may damage the equipment and affect solubility; precise control is essential.

Post-Processing Screening: The raw material is crushed into irregular particles by a crusher, then classified by a fertilizer screener machine. Qualified particles enter subsequent stages, while unqualified coarse particles and fine powder are returned to the pretreatment stage for reprocessing, forming a closed-loop production process and improving raw material utilization. Finally, qualified particles are quantitatively packaged and sealed for storage.

This process is simple and compact, with low energy consumption and strong environmental friendliness. It is suitable for processing various material combinations and is an ideal choice for small- to medium-capacity fertilizer production lines.