In the process of agricultural modernization, the demand for high-quality compound fertilizers has surged, making NPK fertilizer production lines core equipment for fertilizer companies expanding production. However, faced with a variety of equipment and processes, choosing a production line that suits their specific needs is a challenge for many industry professionals.

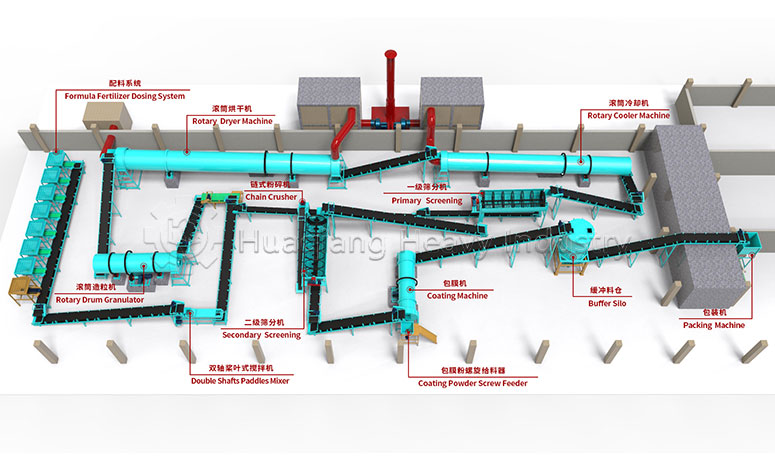

First, let’s look at the core equipment configuration. A complete NPK fertilizer production line needs to cover key stages such as raw material processing, mixing, granulation, drying, and cooling. In the raw material processing stage, a fertilizer crusher can crush large raw materials to a suitable particle size, and with a precise batching system, the proportion of nitrogen, phosphorus, and potassium components can be strictly controlled; for the mixing stage, a fertilizer mixer machine is recommended, and a double shaft paddle mixer can achieve a raw material mixing uniformity of over 95%; granulation is the core process, with disc granulators suitable for small and medium-sized capacities, while double roller press granulators are suitable for high-hardness granule requirements, and companies can choose according to their needs. Subsequent drying, cooling, and coating machines, along with fertilizer screener machines, ensure that the finished granules are uniform and have a qualified moisture content, and finally, automatic packaging is achieved through packaging machines, improving production efficiency.

At the process level, automation is key. A high-quality NPK fertilizer granulation process requires a PLC control system for full monitoring, precisely adjusting parameters from raw material proportioning to drying temperature, ensuring stable nutrient content in the finished product and reducing energy consumption. Choosing the right NPK fertilizer production line is not just about purchasing a set of equipment, but also laying the foundation for the long-term development of the enterprise. Combining capacity, finished product requirements, and manufacturer services will allow the production line to truly become a profit engine.