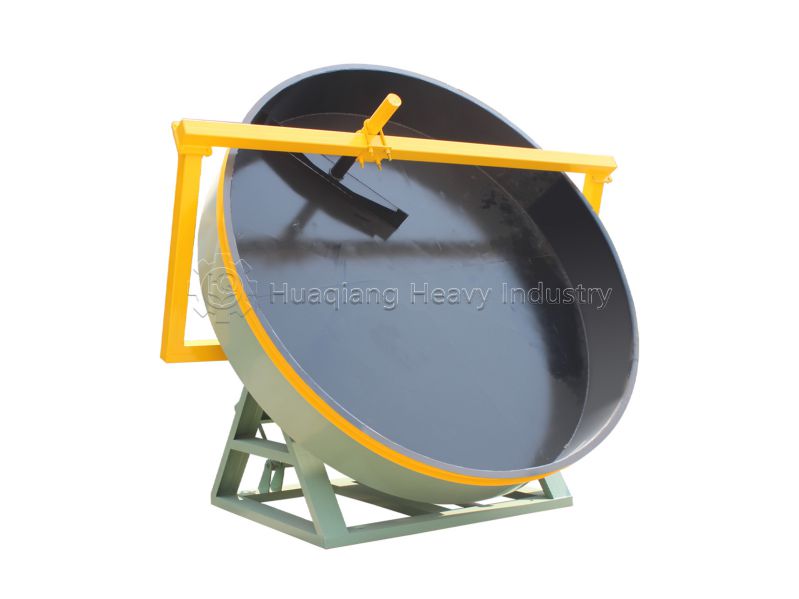

Fertilizer granulators are widely used in the fertilizer industry, and disc granulators are particularly common. What are some common problems with disc granulators in fertilizer production? If problems such as material sedimentation and clumping occur during granulator operation, how can you resolve them? Below, we will guide you through resolving these issues.

Precipitation can occur during fertilizer production. Some materials cannot be mixed; when they are mixed and dissolved in water, precipitation occurs. Some fertilizers are soluble in certain proportions, but above a certain concentration, salting out occurs, causing another material to precipitate. Some materials, such as metal salts, are easily soluble in acidic media, but will precipitate. Other materials, such as humic acid, are easily soluble in alkaline media, but will precipitate when dissolved in acidic solutions.

The main methods to prevent precipitation are to properly adjust the pH of the solution, add cosolvents, and increase the solubility of insoluble substances. The raw materials used in NPK fertilizer production lines should be properly proportioned to prevent salting out and oversaturation. Appropriate additives should be added to protect the reaction materials and prevent precipitation. Appropriate raw materials should be selected to prevent precipitation caused by reactions between them.

Bloating in fertilizer production is caused by the release of gas from the reaction of two or more materials. Materials that may cause bloating during fertilizer production include borax, ammonium salts, and fillers. To effectively prevent bloating, the following points should be noted when using a disc granulator to produce pellets: When sourcing qualified raw materials, avoid blindly pursuing low costs; and ensure that raw materials are properly combined to prevent chemical reactions between them.

Clumping in fertilizer production: This problem is primarily related to the raw materials, humidity, temperature, external pressure, and storage time. Organic fertilizer production equipment requires the proper selection of raw materials, meaning those that are less prone to caking.