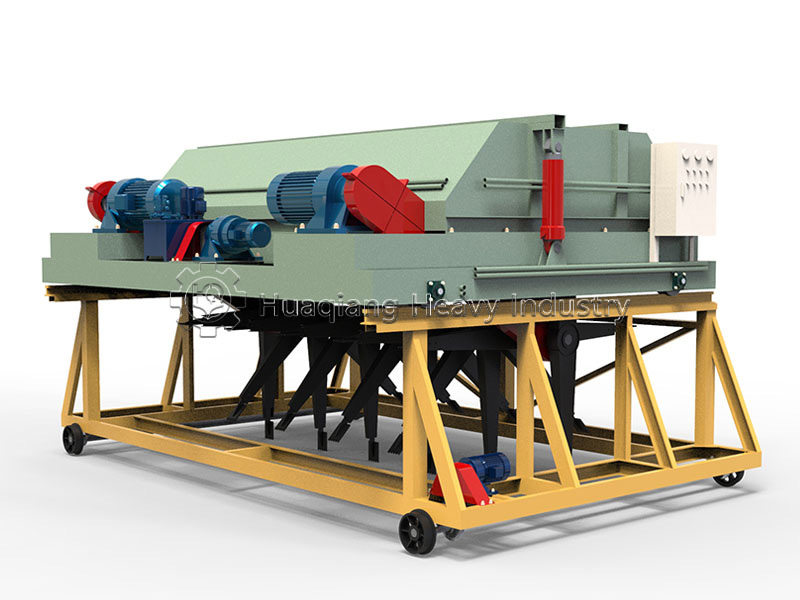

In the entire fertilizer production process, the chain crusher, as a core crushing equipment, directly affects the efficiency of raw material processing, the smoothness of subsequent processing, and the quality of the finished product. To improve overall production efficiency with this equipment, the key lies in achieving precise coordination of raw material adaptation, parameter adjustment, and production process.

Optimize raw material pretreatment. For common lumpy raw materials in fertilizer production (such as agglomerated phosphate rock powder and urea granules), it is necessary to remove hard impurities such as metals and stones in advance to avoid damage to the chain crusher’s hammers and chain plates. At the same time, classify and process raw materials according to their hardness, pre-crushing high-hardness materials to avoid equipment overload caused by mixed crushing, allowing the chain crusher to focus on efficient crushing and increasing the processing capacity per unit time.

Dynamically adapt crushing parameters to match the production rhythm. Flexibly adjust parameters such as the chain crusher’s rotation speed and screen mesh size according to the needs of subsequent processes: if the subsequent process is granulation, the crushing particle size can be controlled at 1-3mm, using a screen with a suitable mesh size to reduce secondary crushing; for raw materials with different moisture content, adjust the rotation speed accordingly—slowing down the speed for high-moisture materials to avoid clogging, and appropriately increasing the speed for dry materials to improve efficiency.

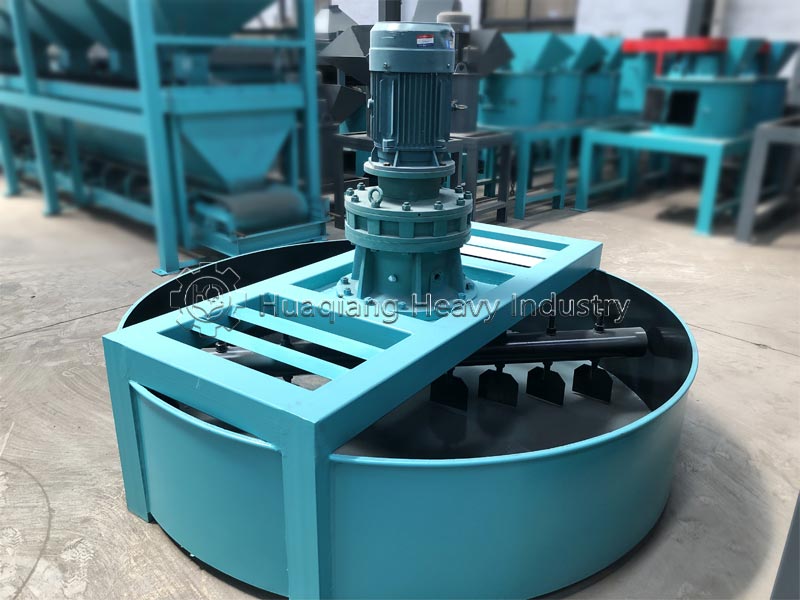

Strengthen the connection throughout the entire process. Coordinate the chain crusher with the upstream raw material conveying and downstream fertilizer screening equipment, using sensing devices to control the feeding speed, avoiding raw material accumulation or interruption of supply. At the same time, regularly clean residual materials in the equipment’s internal cavity and check the wear of the chain plates to reduce equipment downtime due to malfunctions.