The double roller granulator is an advanced equipment based on dry extrusion granulation technology, widely used in multiple industrial fields including fertilizers, chemicals, pharmaceuticals, and feed production. The core advantage of this equipment lies in its ability to efficiently convert powdered raw materials without adding large quantities of binders, providing an environmentally friendly and economical solution for modern industrial production.

Core Working Principle: Five-Step Formation Method

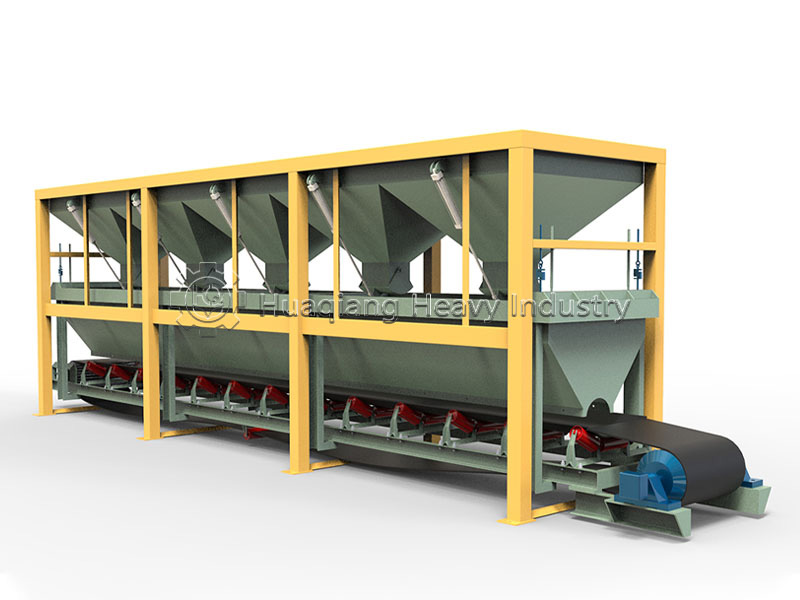

The working process of the double roller granulator can be divided into five closely connected stages. First is the raw material feeding and preprocessing stage, where powdered materials are uniformly transported into the equipment through a precise feeding system. Raw materials require strict preprocessing, including controlling appropriate particle size ranges and moisture content to ensure subsequent forming effectiveness.

Next is the crucial roller extrusion forming stage. The core of the equipment consists of a pair of horizontally installed, counter-rotating press rollers made from high-strength wear-resistant materials. When raw materials enter the nip zone between the rollers, tremendous mechanical pressure compresses the powdered material into a dense sheet structure. During this process, air between raw material particles is expelled, molecular distances are reduced, and stable molded bodies are formed through physical forces.

The sheet material formed by extrusion then enters the crushing stage, where it is broken into particles of varying sizes. These particles undergo screening and classification systems, separated according to predetermined sizes. Particles meeting requirements are output as finished products, while oversized or undersized particles return to corresponding processes for reprocessing, ensuring raw material recycling.

Design Features and Technological Innovation

The successful operation of double roller granulators relies on multiple carefully designed technical features. Roller surface design can be adjusted according to raw material characteristics – grooved design increases contact area, while smooth design suits more viscous materials. The fine adjustment function of roller clearance allows the equipment to adapt to different raw material forming requirements.

The equipment’s synchronized rotation system ensures coordinated operation of both press rollers, preventing material deviation. This precise mechanical design not only improves forming efficiency but also guarantees product consistency. The advantages of dry granulation are fully demonstrated in this process – requiring no large amounts of water or binders saves costs while maintaining raw material purity.

Application Fields and Environmental Value

The application scope of double roller granulators is extensive. In fertilizer production, they can uniformly granulate various nutrient elements, improving fertilizer efficiency and application convenience. The chemical industry utilizes this equipment to process dust and powdered raw materials, achieving effective resource utilization. The pharmaceutical industry relies on it to produce uniform drug granules, ensuring product quality.

Compared to traditional wet granulation, double roller granulators offer significant environmental advantages. By eliminating the need for large quantities of water resources and binders, they reduce wastewater discharge and energy consumption. Meanwhile, high raw material recycling rates of 85-95% maximize raw material utilization while minimizing waste.

Future Development Trends

With continuous advancement in industrial technology, double roller granulators are developing toward greater intelligence and efficiency. New material applications improve equipment wear resistance and service life, while the introduction of automated control systems makes operation simpler and more precise.

In the future, this equipment is expected to play roles in more fields, particularly in resource recycling and environmental protection. By converting various industrial by-products into valuable granular products, double roller granulators will make important contributions to the development of circular economy, promoting industrial production toward more sustainable directions.

Diverse Granulation Technologies in Modern Fertilizer Manufacturing

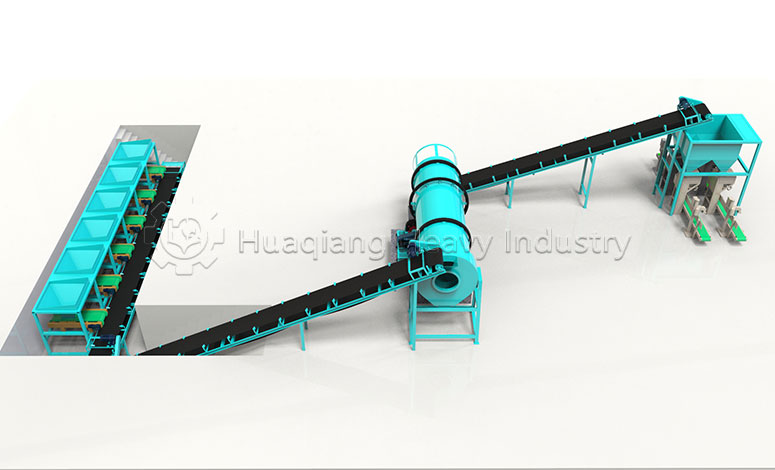

The double roller press granulator represents a pivotal advancement in dry fertilizer granules compaction technology, offering distinct advantages within the broader npk fertilizer production technology landscape. As a specialized fertilizer compaction machine, this equipment operates on principles fundamentally different from wet granulation methods like drum granulation typically associated with rotary drum granulator systems. The complete roller press granulator production line integrates this core equipment with auxiliary systems to form an efficient fertilizer production machine configuration suitable for specific production requirements.

While wet granulation remains prevalent in conventional npk manufacturing process lines, dry compaction technology provides complementary capabilities for moisture-sensitive formulations or specialized products. Modern npk production line designs increasingly incorporate flexibility to utilize different granulation methods based on raw material characteristics and final product specifications. This technological diversity within npk fertilizer production technology enables manufacturers to optimize production efficiency, product quality, and resource utilization, supporting the industry’s evolution toward more sustainable and versatile manufacturing solutions that meet diverse agricultural needs while minimizing environmental impact through efficient fertilizer granules compaction and processing methods.