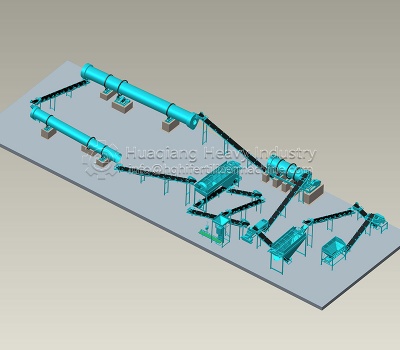

In the field of organic fertilizer production, technological innovation has always been the core driving force for industry progress. A new type two in one organic fertilizer granulator that integrates mixing and granulation processes is quietly changing the traditional production model, bringing a brand-new solution to the industry.

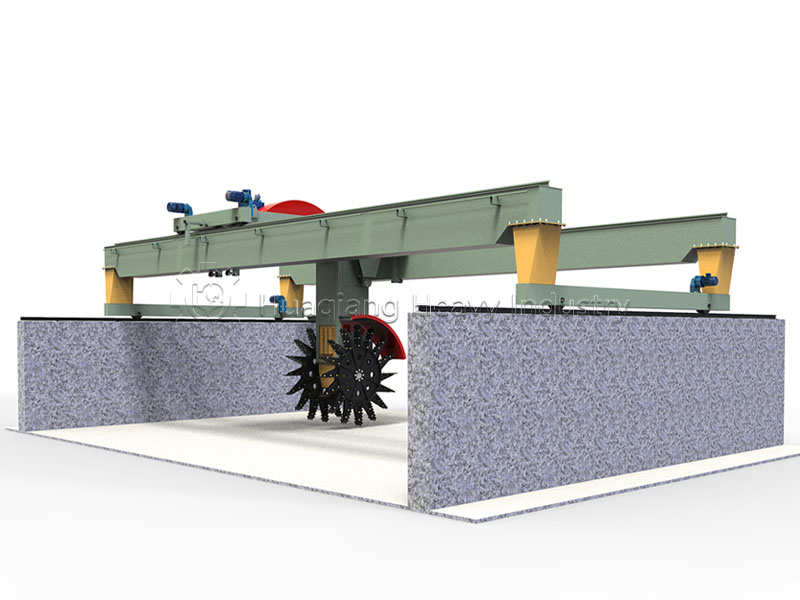

This new two-in-one equipment innovatively integrates two major functions into a single machine, enabling materials to be continuously mixed and granulated within the same working unit, simplifying the process and improving overall consistency.

In terms of granulation technology, the most common organic fertilizer production equipment on the market is mainly divided into flat die pelleting machines and ring die pelleting machines. This new two-in-one equipment does not simply replace either of them, but rather draws on the design essence of different granulation technologies. Its emergence means that producers can reduce equipment investment and maintenance costs, while reducing energy consumption and space occupation during the production process. For modern fertilizer companies pursuing production efficiency and resource optimization, this is undoubtedly a highly attractive option.

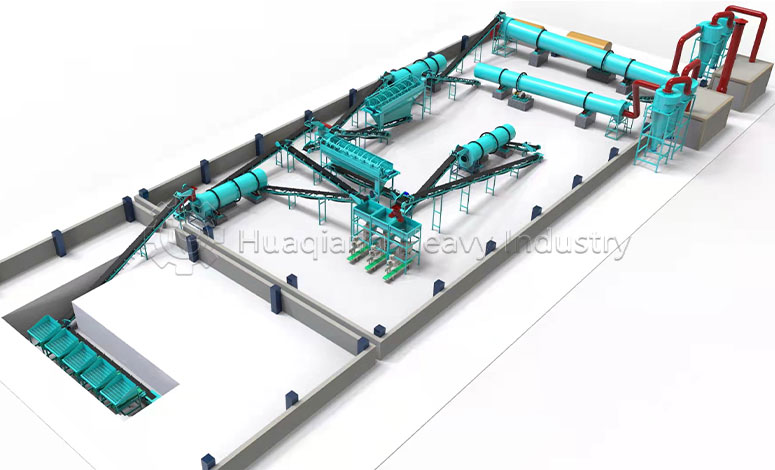

In conclusion, this new type organic fertilizer production equipment, integrating mixing and granulation, represents a shift in organic fertilizer equipment towards greater intensification, efficiency, and intelligence. It serves as a powerful complement to traditional technologies such as flat die pelleting machines and ring die pelleting machines, and represents a new approach to future production line construction.

.jpg)