How Do Five Processes Achieve the Magnificent Transformation from Powder to Perfect Particles?

The Perfect Performance of Precision Process

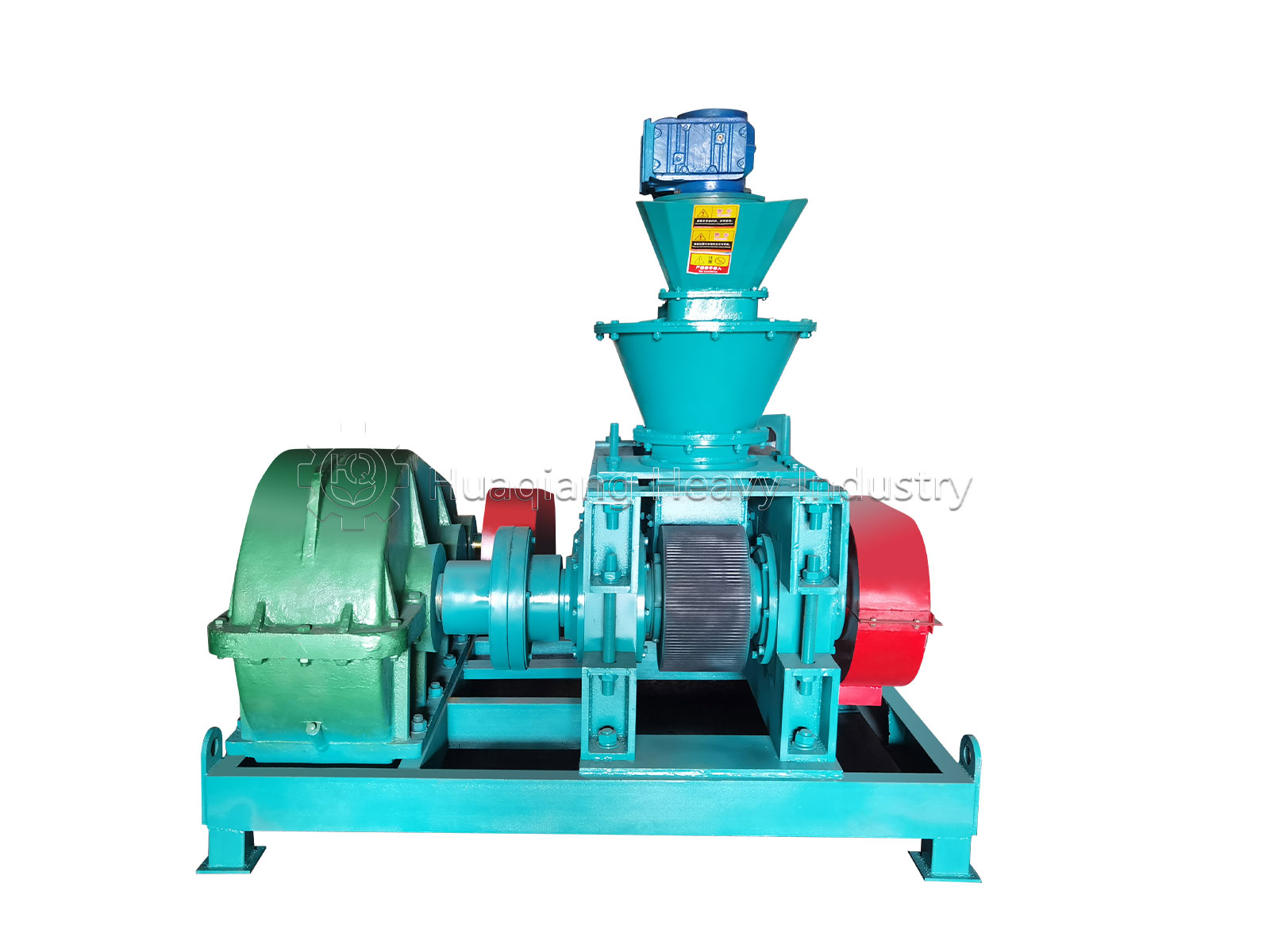

The hydraulic roller granulator is the core component of an NPK fertilizer production line. Its workflow resembles a carefully choreographed industrial ballet, with five interrelated processes working in harmony to transform loose fertilizer powder into uniform, high-quality granules. At its core lies the art of fertilizer granulation: once the raw materials enter the system, the roller granulator (a specialized fertilizer compactor) applies precise hydraulic pressure to compress the powder into dense, cohesive strands, which are then shaped and graded.

This fertilizer production machine does more than simply drive simple physical changes; it deeply optimizes material properties, enhancing granule hardness, solubility, and nutrient concentration—all crucial to the effectiveness of NPK fertilizers. Unlike general-purpose equipment, this fertilizer compactor is specifically designed to handle the unique characteristics of compound fertilizer mixtures, ensuring a uniform nutrient ratio in each granule. Each step, from feeding to final compaction, is synchronized to transform loose powder into marketable granules, making the hydraulic roller granulator an indispensable component of modern NPK fertilizer production line operations.

Material Pretreatment

Raw materials first undergo preprocessing steps including crushing, screening, and precise mixing to ensure ideal uniformity and particle size distribution. Meanwhile, material humidity and viscosity are precisely controlled to create optimal conditions for subsequent granulation processes.

Precision Feeding and Conveying

Pre-treated materials are evenly fed between the granulator rollers through precision feeding systems. Accurate control of the feeding system is crucial for ensuring uniform material distribution and continuity of the granulation process.

High-Pressure Extrusion Molding

When materials enter the roller gap, the hydraulic system provides stable high pressure, enabling two sets of rotating rollers to apply tremendous pressure to the materials. Under high pressure, materials undergo plastic deformation, molecular distances decrease, inter-particle voids are compressed, and finally bond and form under high pressure.

Particle Formation and Discharge

Under the extrusion effect of the rollers, materials gradually form continuous strip structures. As the rollers rotate, the strip materials are extruded and naturally break into particles. These particles exhibit excellent hardness and stability, suitable for direct use in subsequent processing or direct application.

Cooling and Post-treatment

For specific materials, granulated particles may require cooling treatment to stabilize the structure and prevent deformation or adhesion due to high temperatures. Cooled particles can also be processed through crushing and screening systems to remove non-conforming products, ensuring final product quality.

Outstanding Equipment Features

The six core characteristics of hydraulic roller granulators make them stand out among numerous granulation equipment, becoming the ideal choice for industrial production.

Efficient Granulation

Achieves efficient material extrusion molding through precise control of roller pressure and speed, significantly improving production efficiency

High-Quality Particles

Granulated material particles exhibit good hardness, stability, and uniformity, meeting stringent quality requirements across various industries

Wide Applicability

Suitable for granulation processing of various dry powder and slightly wet materials, demonstrating excellent material adaptability

High Automation

Equipped with advanced control systems, easy to operate and maintain, significantly reducing manual intervention requirements

Energy Saving & Eco-friendly

Efficient hydraulic system operation, low energy consumption in granulation process, minimal dust and noise pollution, compliant with modern environmental standards

Stable & Reliable

Continuous and stable granulation process ensures product quality consistency, providing reliable guarantee for large-scale production

Deep Embodiment of Innovative Value

The working principle of hydraulic roller granulators not only showcases the precision beauty of mechanical engineering but also reflects modern manufacturing technology’s deep understanding of materials science. From fertilizer production to chemical raw materials, from metallurgical processing to food additives, this innovative granulation method is providing more efficient and environmentally friendly production solutions for various industries. Its unique high-pressure extrusion technology ensures excellent product quality, while the intelligent control system significantly improves production efficiency and operational convenience. More importantly, the entire granulation process is green and environmentally friendly, fully complying with modern industrial sustainable development concepts.

Hydraulic Roller Granulator – Reshaping Material Forms with Precision Processes, Empowering Industrial Upgrading