The production process of chicken manure organic fertilizer production line equipment and the environmental advantages it brings. Organic fertilizer, as an important agricultural resource, can not only improve soil quality and increase crop yield, but also reduce the impact of chemical fertilizers on the environment. It can be said to be an important support for the sustainable development of modern agriculture.

1、 Raw material collection and processing

The production process of chicken manure organic fertilizer production line starts from the collection and processing of raw materials. These raw materials include organic waste such as agricultural waste, livestock manure, and plant straw. These wastes are processed through composting and other methods, decomposed and fermented, and gradually transformed into organic matter, providing a foundation for the subsequent production of chicken manure organic fertilizers.

2、 Fermentation treatment

During this process, chicken manure will be stacked in the fermentation pile, and through the action of microorganisms, organic matter will gradually decompose into organic acids, ammonia, and other substances. This process requires attention to controlling temperature, ventilation, and other conditions to promote microbial growth and organic matter decomposition..jpg)

3、 Flipping and conditioning

The fermentation process usually requires multiple flipping and conditioning to ensure uniformity and sufficient oxygen supply inside the material pile. This process helps to accelerate the fermentation process and improve the efficiency of organic matter decomposition. In this step, it is necessary to use equipment such as organic fertilizer turners for operation to reduce manual labor intensity.

4、 Drying and crushing

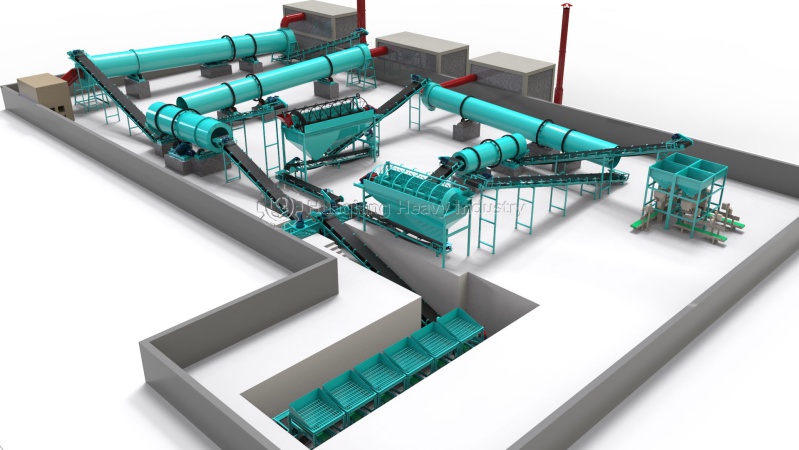

The organic fertilizer after fermentation has a high moisture content and needs to be dried. The drying process usually uses equipment such as a rotary dryer to evaporate the moisture in the fertilizer and achieve a suitable storage level. Subsequently, the dry organic fertilizer will be sent into a crusher for fine crushing treatment, ensuring that the particle size of the fertilizer is moderate and convenient for application.

5、 Packaging and storage

After drying and crushing, organic fertilizers will be packaged for transportation and storage. Common packaging methods include bagging, bulk packaging, etc., which should be selected according to actual needs. In addition, quality testing is required before packaging to ensure that organic fertilizers meet national standards.

Through the above steps, the equipment of the chicken manure organic fertilizer production line has completed the entire production process from raw material collection to finished product packaging. In this process, the coordination and application of various professional equipment played a crucial role, not only improving production efficiency, but also ensuring the quality and stability of organic fertilizers.

.jpg)

.jpg)

.jpg)

.jpg)