NPK fertilizer (nitrogen-phosphorus-potassium compound fertilizer) production lines are core equipment for modern agriculture. By scientifically blending nitrogen, phosphorus, and potassium, they provide precise nutrients to crops. This is of great significance to high-quality agricultural development, and its impact is reflected in three key areas.

NPK fertilizer production lines are a stabilizer for ensuring food security. With population growth and limited arable land, increasing yields is crucial. NPK fertilizer production lines can customize balanced compound fertilizers based on the fertilizer needs of crops like wheat and rice, addressing the nutrient deficiencies of traditional single fertilizers. Data shows that high-quality NPK compound fertilizers can increase grain yields by 15%-25% per mu, effectively alleviating pressure on food supply and strengthening national food security.

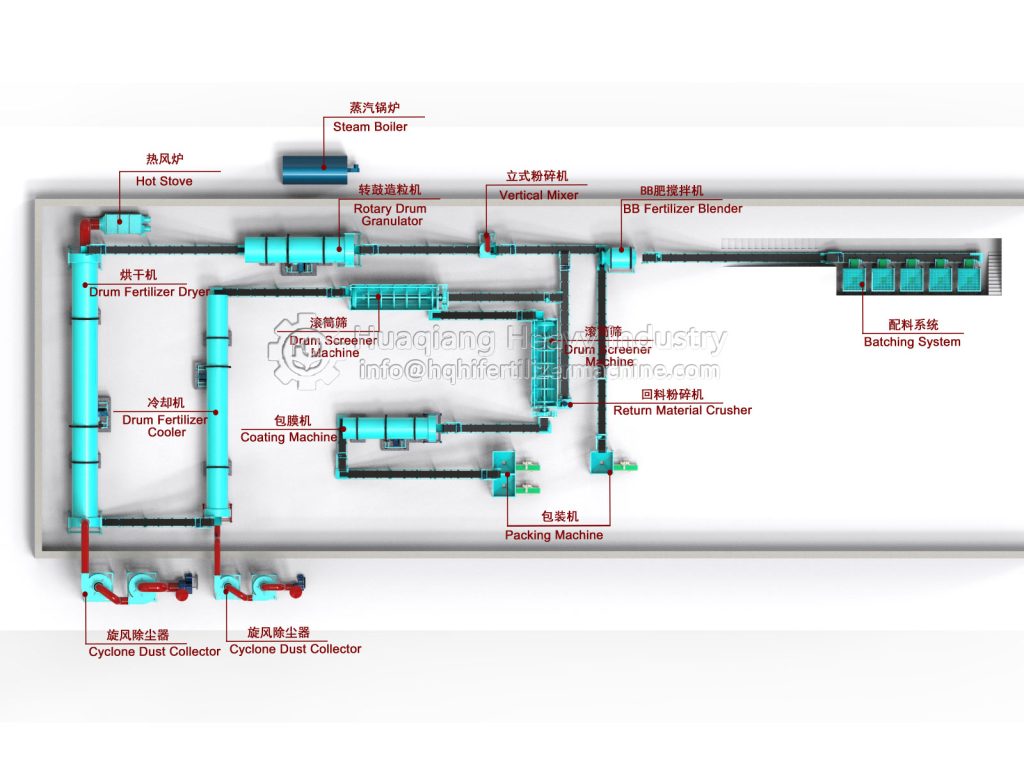

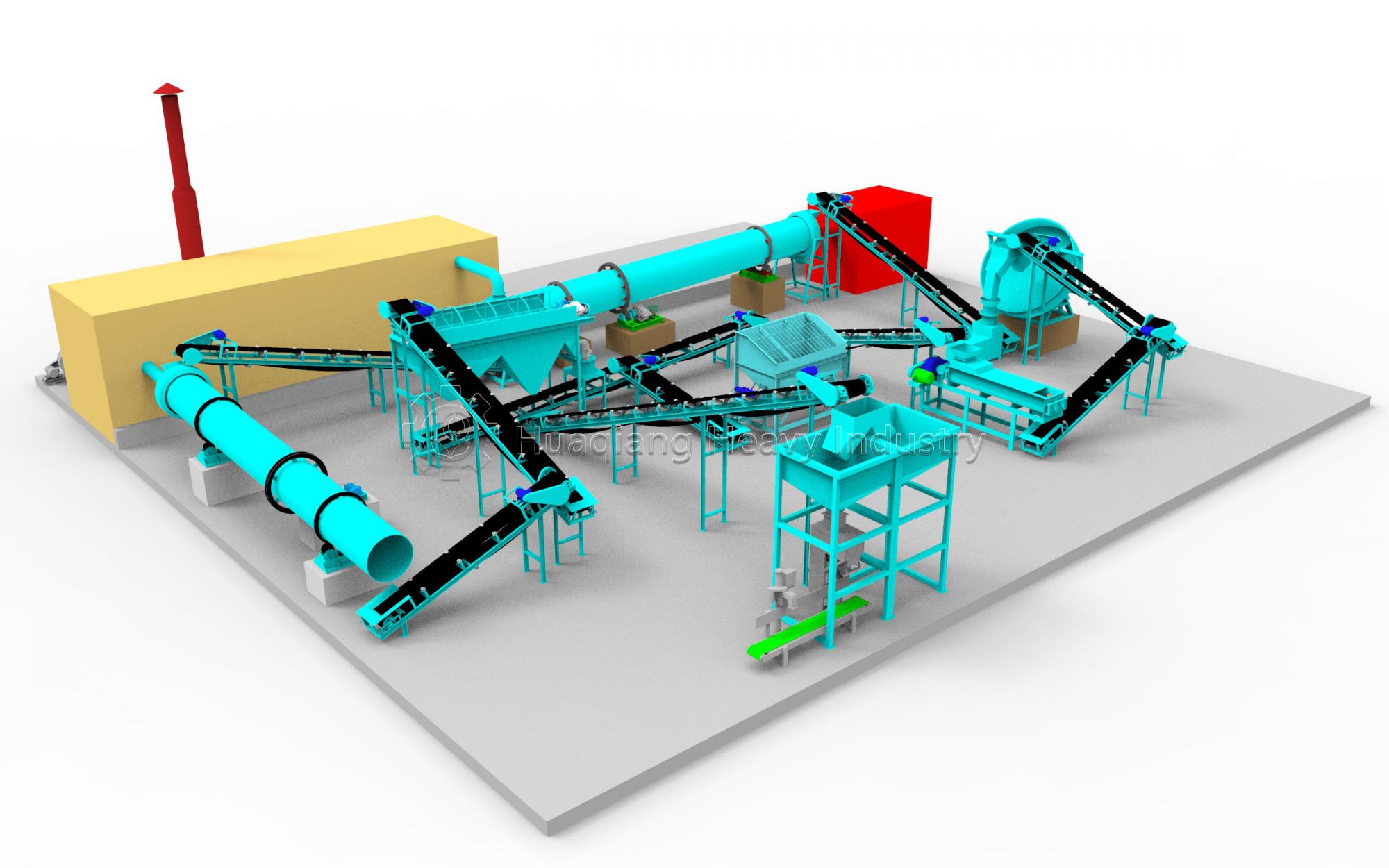

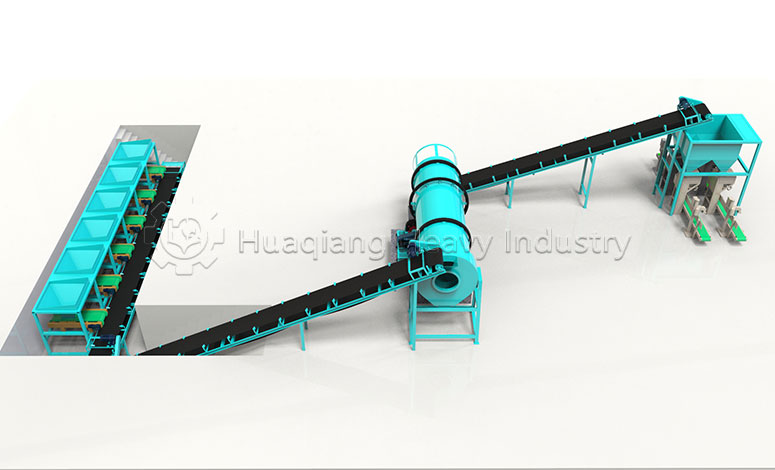

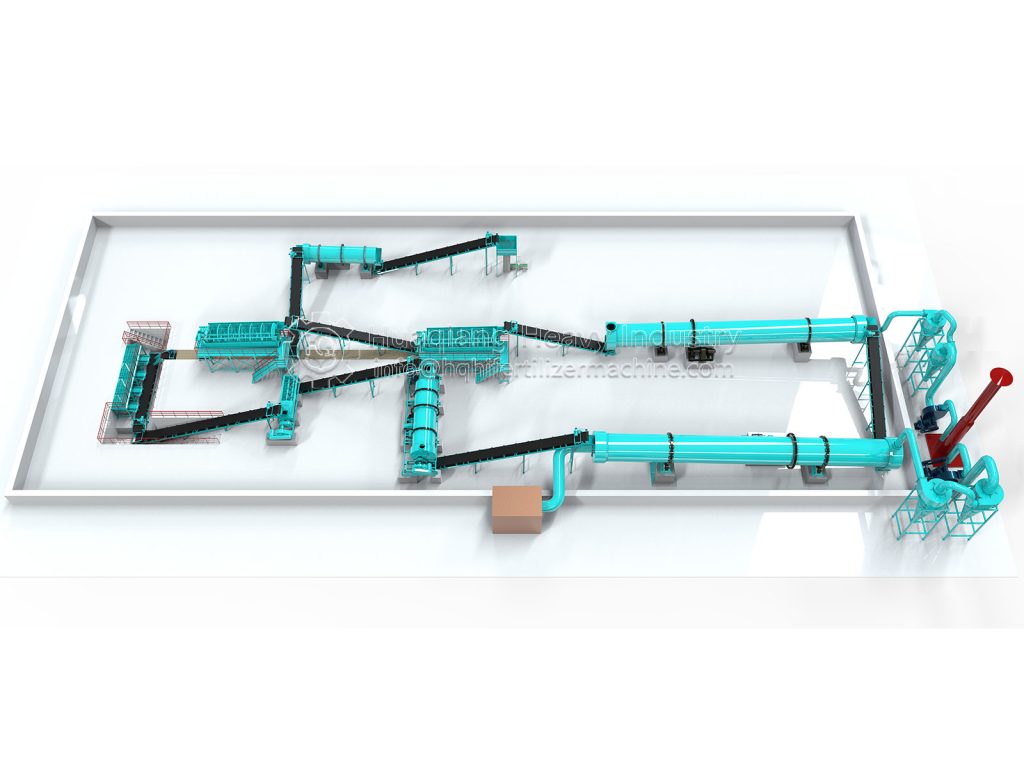

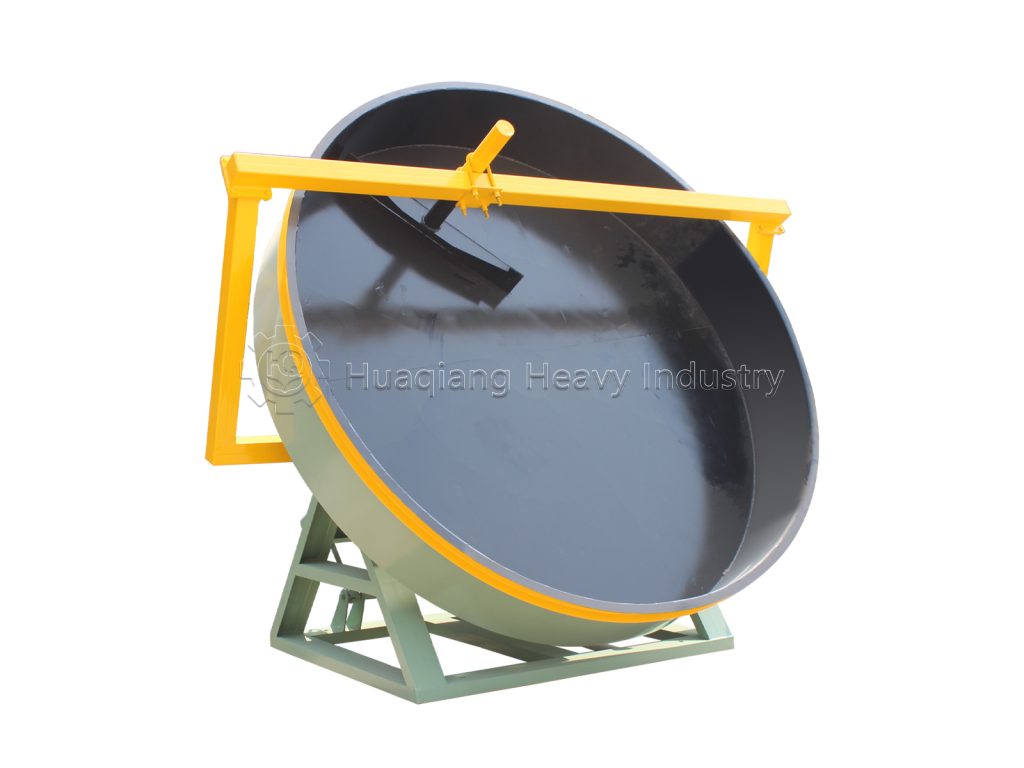

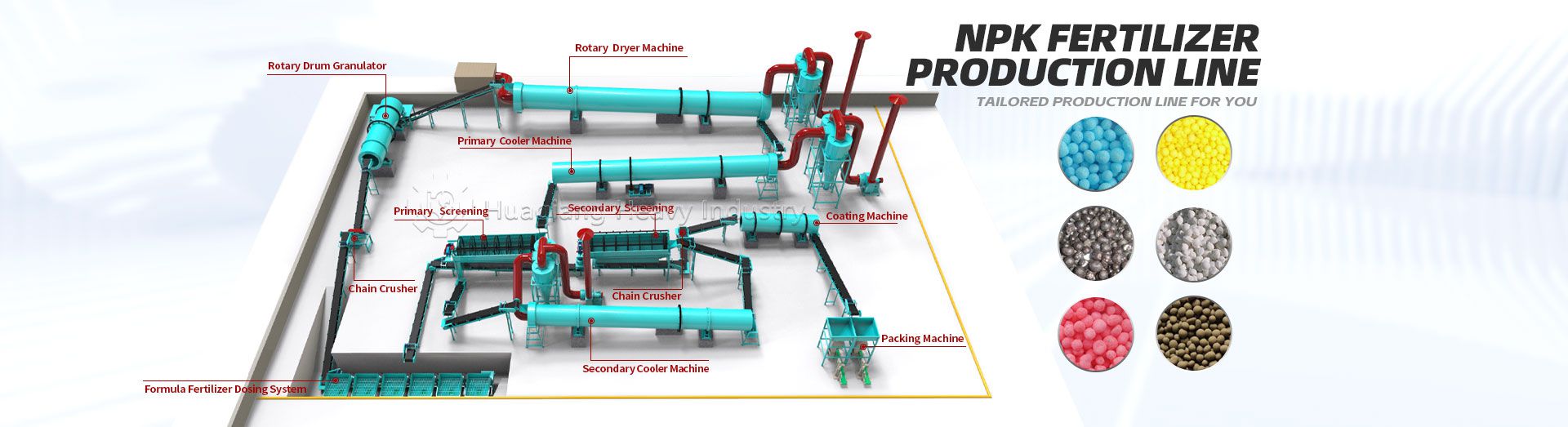

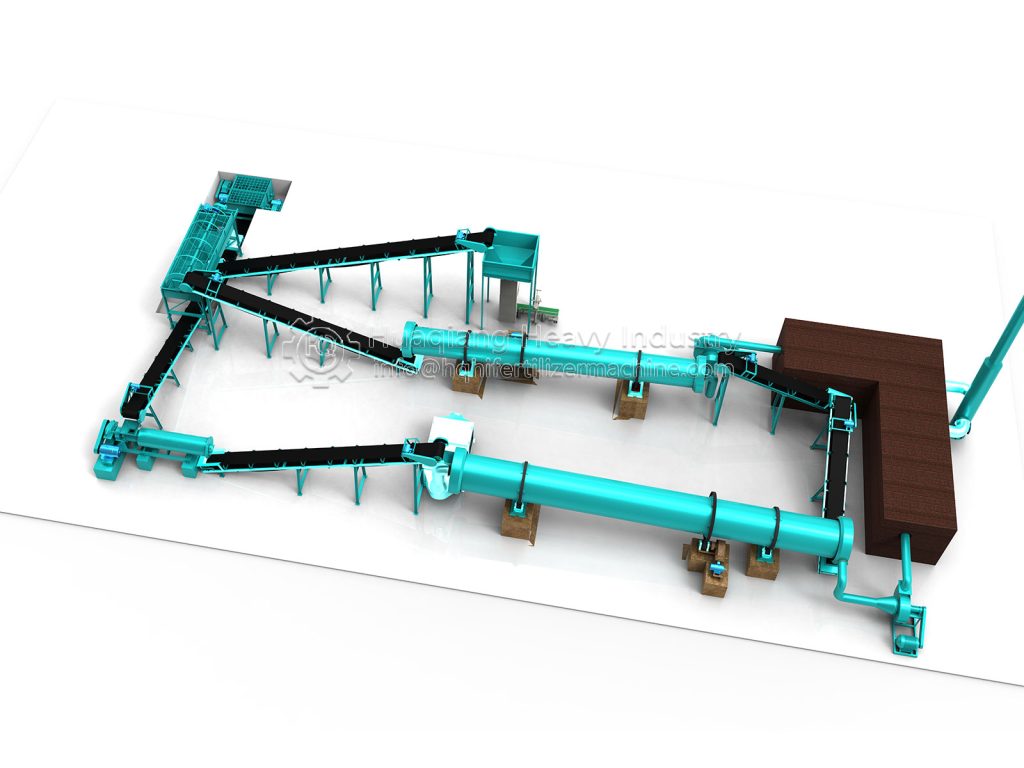

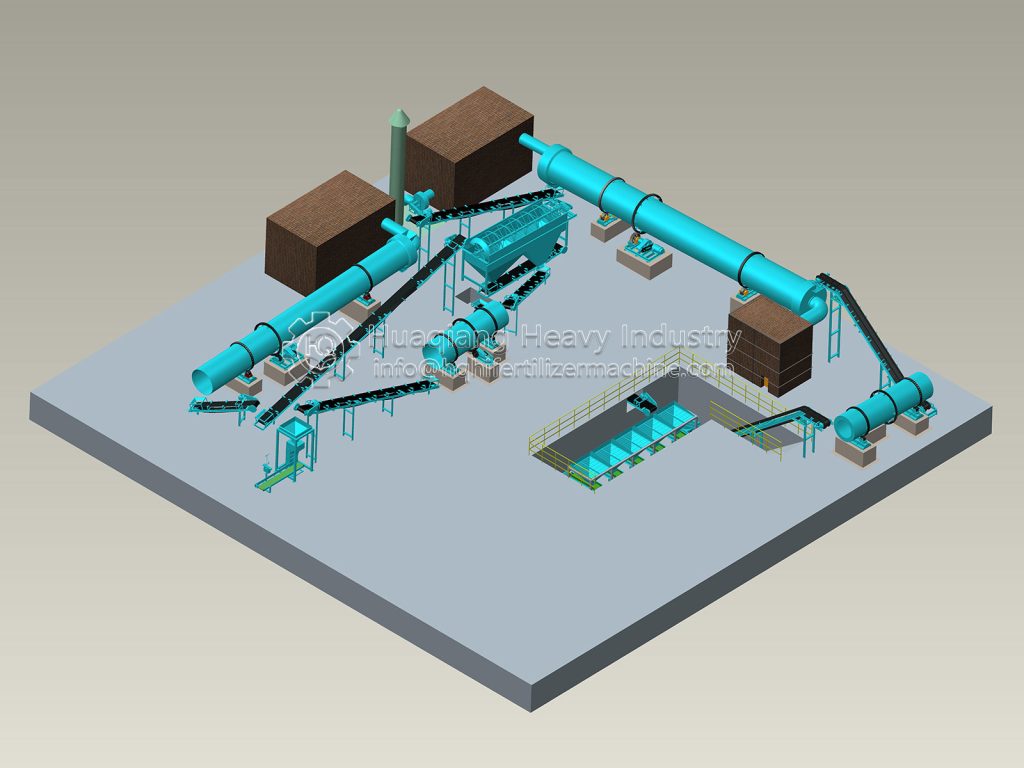

NPK fertilizer production lines are an accelerator for promoting agricultural modernization. Traditional fertilizer production relies on manual labor, resulting in low efficiency and uneven nutrient distribution. NPK production lines, however, fully automate raw material mixing, granulation, drying, and packaging. A modern production line can produce hundreds of tons of fertilizer per day, significantly improving efficiency. Precise temperature and humidity control ensures uniform fertilizer particles and consistent nutrient content, reducing fertilizer waste and helping transform agriculture from extensive to intensive farming.

NPK fertilizer production lines are the “guardians” of sustainable agriculture. Today, NPK production lines can incorporate slow-release technology to produce slow-release compound fertilizers, which slowly release nutrients, prolong fertilizer effectiveness, and reduce soil and water pollution caused by fertilizer runoff. Some lines can also utilize agricultural waste such as straw and livestock manure as auxiliary materials, achieving resource recycling and reducing the environmental impact of chemical fertilizer production, meeting the needs of green agriculture.

In short, by ensuring yield, improving efficiency, and promoting green development, NPK fertilizer production lines have become an indispensable core force in agricultural modernization, injecting lasting momentum into sustainable agricultural development.