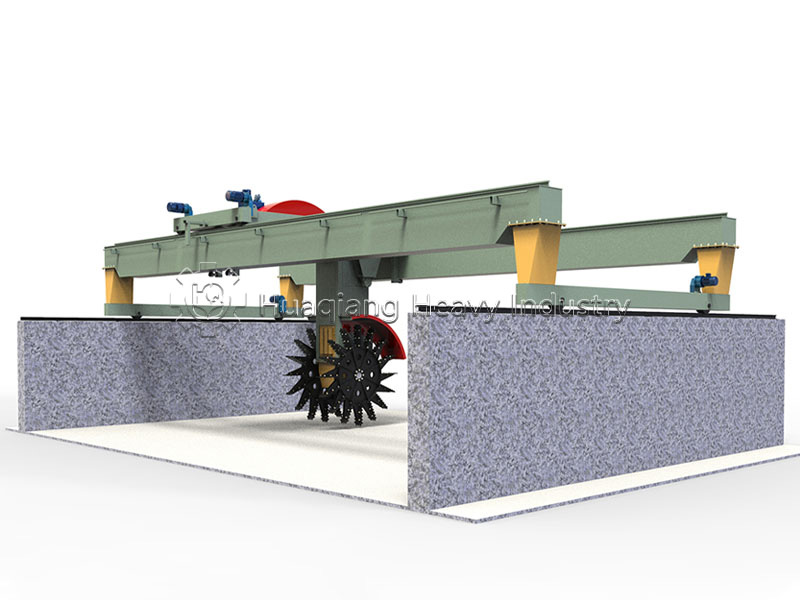

In modern organic fertilizer production lines, the rotary drum granulator, as a key piece of equipment, ensures the continuous and stable production process through its unique operating mode. This continuously operating cylindrical system is not only the core link in material forming but also a crucial hub connecting upstream and downstream processes.

From the perspective of the overall layout of the organic fertilizer production line, the rotary drum granulator occupies a critical position, connecting the preceding and following stages. Within the family of organic fertilizer granulators, the rotary drum type exhibits unique technological advantages. Compared to other types of organic fertilizer granulators, its continuous operation mode is particularly suitable for the needs of large-scale industrial production. The cleverly designed lifting plates and flow guiding devices inside the drum ensure thorough mixing of materials during the granulation process.

The rotary drum granulator demonstrates excellent stability in organic fertilizer production lines. The equipment can adapt to different organic raw material formulations, whether it’s livestock manure or straw waste, achieving ideal granulation results by adjusting operating parameters. This adaptability makes it an indispensable part of modern organic fertilizer production equipment.

From a production efficiency perspective, rotary drum granulators play a crucial role in organic fertilizer production lines. Their low energy consumption and maintenance costs, coupled with stable yield rates, create significant economic benefits for production enterprises.

With the continuous development of the organic fertilizer industry, rotary drum granulation technology is also constantly innovating, providing more reliable equipment support for organic fertilizer production lines.

.jpg)