Characteristics and benefits of fertilizers processed on biological organic fertilizer production lines

Organic fertilizer is mainly derived from plants and (or) animals, and is applied to the soil to provide plant nutrition as a carbonaceous material with its main function. Processed from biological materials, animal and plant wastes, and plant residues, the toxic and harmful substances are eliminated, and it is rich in a large number of beneficial substances, including: a variety of organic acids, peptides, and abundance including nitrogen, phosphorus, and potassium Of nutrients. It can not only provide comprehensive nutrition for crops, but also has long fertilizer efficiency, which can increase and renew soil organic matter, stimulate microbial reproduction, and improve soil physical and chemical properties and biological activity. It is the main nutrient for green food production. As long as the fertilizer granulator is selected correctly, the npk fertilizer manufacturing process can also produce organic fertilizer.

Organic fertilizers are rich in organic matter, which can provide nutrients for crop growth, and can also improve soil fertility. There are many kinds of organic fertilizers, the raw materials are very wide, and the fertilizers are also ever-changing. It provides the nutrients needed for crop growth, with comprehensive nutrients. It contains 16 kinds of nutrients necessary for crop growth, as well as other elements beneficial to crop growth. It can fully stimulate crop growth and release nutrients evenly and for a long time. Organic fertilizer contains more nutrients. It exists in the organic form, which can be released slowly and supply crop nutrients for a long time. The application of organic fertilizer can improve soil structure and enhance soil fertility. Organic fertilizer can increase soil water holding capacity, generally by about 10 times. It also has good drainage, so it can alleviate the difference between soil dryness and wetness, so that the root environment of crops will not be excessive. Big or too small.

.jpg)

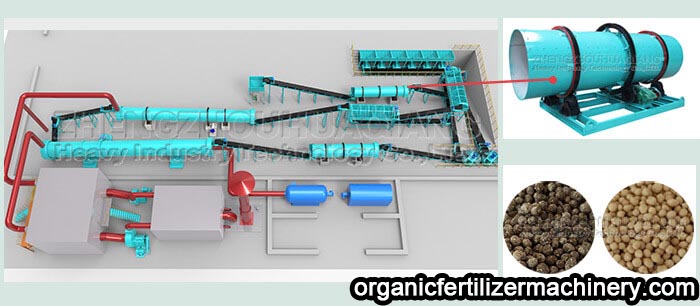

Composition of organic fertilizer production line equipment

The equipment of the organic fertilizer production line is similar to the equipments required for biofertilizer production.

The equipment of the organic fertilizer production line consists of: belt conveyor → bucket elevator → vertical grinder → horizontal grinder → vertical mixer → disc granulator → drum granulator → rotary dryer → rotary cooler →Classification screen→cyclone dust collector→hot blast stove and other fertilizer manufacturing equipment.

.jpg)

.jpg)

.jpg)