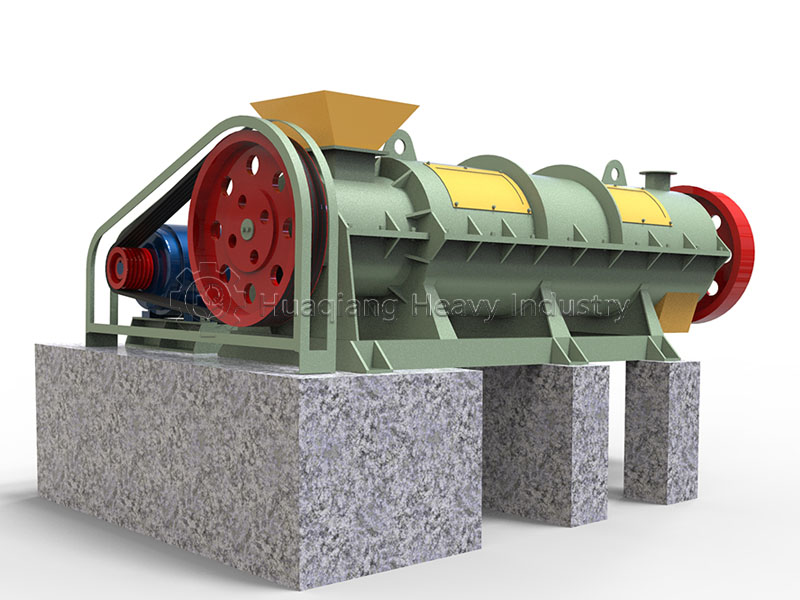

In organic fertilizer production, the challenge of bridging the gap between “mixing” and “granulation” is often amplified by differences in raw material characteristics. The new type two in one organic fertilizer granulator, integrating mixing and granulation, solves these problems with a design more closely suited to the characteristics of the raw materials.

Its most prominent advantage is its ability to handle “dry-wet mixtures.” For example, when mixing fresh chicken manure with a moisture content of 30% with dry straw powder with a moisture content of only 12%, the fertilizer granulator, within the same chamber, first uses the staggered rotation of a spiral stirring paddle to quickly interweave and blend the dry and wet materials. Simultaneously, a built-in micro-humidification device replenishes moisture to the dry material and guides the wet material to dry, resulting in a stable moisture content of 18%-22% after mixing.

It can also precisely control the proportions when dealing with “multi-component mixtures” of raw materials. Many organic fertilizers mix 3-4 raw materials, such as mushroom residue, rice husks, and humus, to enhance fertilizer efficiency. However, the densities of these different raw materials vary greatly. The new type two in one organic fertilizer granulator can automatically adjust the mixing speed according to the density of the raw materials. It slows down the mixing of heavier materials and speeds up the mixing of lighter materials, ensuring precise proportions of each raw material.

Even “difficult-to-bind fibrous raw materials” can be handled effectively. Raw materials like rice husks and peanut shells, with a fiber content exceeding 40%, tend to be loose when mixed alone. During the mixing stage, the two-in-one model uses a built-in shearing blade to cut long fibers into short fibers of 2-3 mm, which are then thoroughly mixed with other raw materials to form a mixture of “fiber skeleton + binding component.” No additional binder is needed during subsequent granulation, and the granules achieve the required hardness.