In modern agricultural production, the quality of fertilizer granules directly affects fertilization efficiency and crop yield. Wet granulation technology, as a crucial process in fertilizer production, is changing the landscape of fertilizer manufacturing with its unique advantages, especially for the production of NPK blended fertilizers, where wet granulation demonstrates irreplaceable technical value.

Continuous Production: The Perfect Combination of Efficiency and Stability

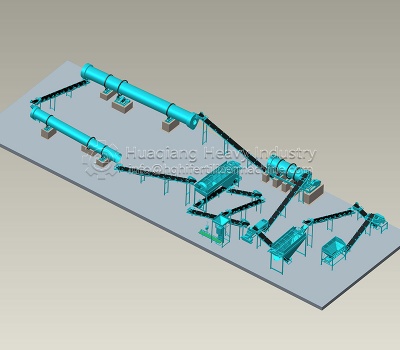

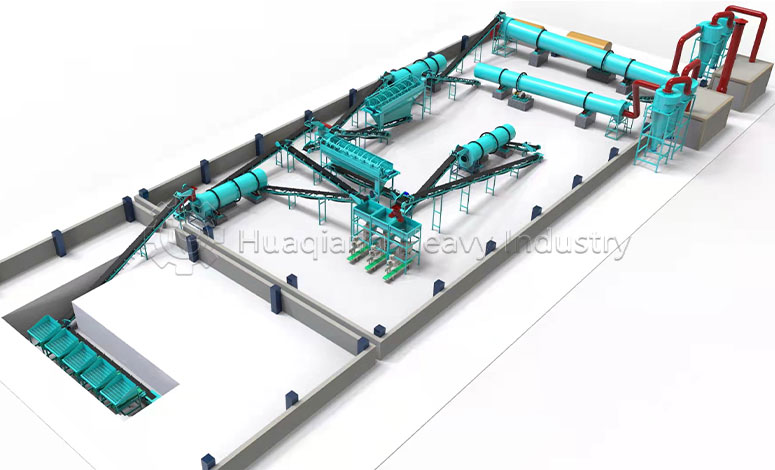

Traditional fertilizer granulation often employs a batch-type operation mode, limiting production efficiency and making it difficult to maintain consistent quality between batches. The new continuous wet granulation technology overcomes this limitation, achieving seamless connection and continuous flow of raw material mixing, conditioning, granulation, and drying. This continuous operation mode not only significantly improves the production efficiency of NPK blended fertilizers but also ensures the consistent quality of each batch of fertilizer granules through stable process parameter control.

In large-scale production scenarios, the continuous production line can operate 24 hours a day, significantly reducing energy consumption and labor costs per unit of product. This is of great significance for meeting the large-scale fertilizer needs of modern agriculture, enabling fertilizer production enterprises to maximize economic benefits while ensuring quality.

Precise Wet Conditioning: A Combination of Science and Art

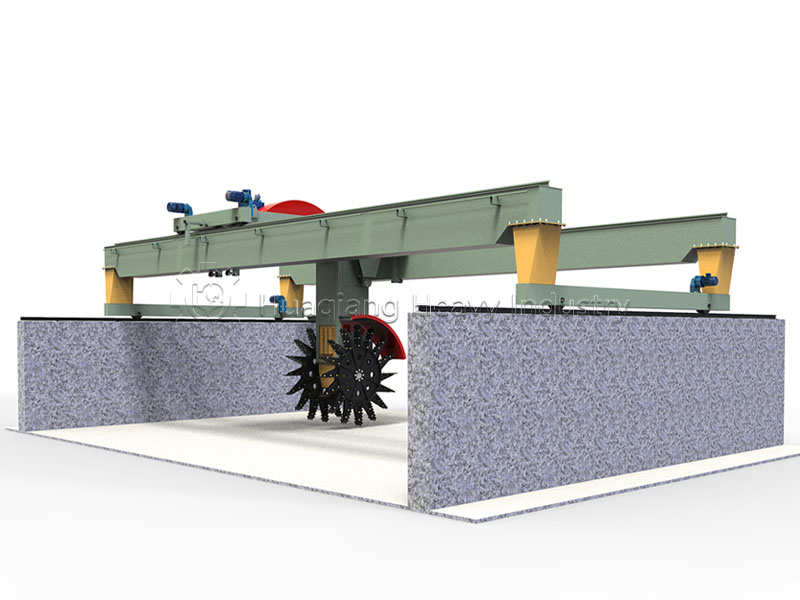

The core of wet granulation lies in the precise control of moisture and binders. In NPK blended fertilizer production, nitrogen, phosphorus, and potassium raw material powders need to reach the optimal binding state to form strong and uniform granules. The new granulator, through advanced sensors and control systems, monitors material humidity in real time and precisely adjusts the amount of water or binder added, ensuring that the raw materials are in the most suitable state for granulation.

The advantages of this precise conditioning are: firstly, it allows for uniform mixing of fertilizer components with different densities, avoiding nutrient stratification and ensuring that each fertilizer granule contains a balanced amount of nitrogen, phosphorus, and potassium; secondly, appropriate humidity conditions are conducive to granule formation and solidification, resulting in high-strength granules that are less prone to breakage during packaging, transportation, and application; finally, the wet process is relatively gentle, reducing nutrient volatilization and loss, and ensuring the stability of fertilizer efficacy.

Patented Structural Design: Flexibility to Adapt to Diverse Formulations

Different crops and soil conditions require NPK fertilizers with different ratios, which places higher demands on granulation equipment. The new granulation equipment utilizes a patented structural design, specifically optimized for material feeding and granule formation. This allows it to adapt to various NPK raw material ratios, ensuring stable and efficient granulation production regardless of whether the formula is high-nitrogen, high-phosphorus, or high-potassium.

This design flexibility is not only reflected in the raw material ratios but also in its adaptability to the physical characteristics of the raw materials. Fertilizer raw materials from different sources may vary in particle size, density, and hygroscopicity. The optimized granulation system can automatically adjust parameters to ensure the production of high-quality fertilizer granules under various conditions.

Product Advantages and Application Value

NPK blended fertilizers produced through wet granulation offer significant product advantages: high granule uniformity and consistent size, facilitating mechanized application and enabling precise fertilization; low dust content, reducing environmental pollution and health risks for operators; and moderate granule hardness, ensuring integrity during storage and transportation while allowing for gradual disintegration in the soil to release nutrients effectively.

As modern agriculture moves towards precision and mechanization, wet granulation technology will continue to play a crucial role. It not only improves the production efficiency and quality stability of fertilizers but also provides technical support for customized fertilizer production, enabling agricultural producers to obtain the most suitable fertilizer products according to their specific needs, ultimately achieving improved quality, increased efficiency, and sustainable development in agricultural production.

Integrated Production Systems: The Science of High-Quality NPK Fertilizers

The advanced wet granulation process is a cornerstone of modern npk fertilizer production technology, seamlessly integrated into a complete npk fertilizer production line. This sophisticated npk fertilizer manufacturing process begins with precise formulation using specialized equipment like the npk blending machine or bulk blending fertilizer machine. The uniformly mixed powder then undergoes controlled wet conditioning, often in a fertilizer mixer machine, before entering the core granulation stage.

This stage utilizes advanced npk granulation machine technology, where equipment such as the npk fertilizer granulator machine transforms the moistened material into uniform, robust pellets through the process of fertilizer granulation. The choice of npk granulation machine is critical, determining the physical quality and efficiency of the final product. The entire system, comprising these specialized npk fertilizer machine units, exemplifies the precision and innovation behind the manufacturing of npk fertilizer. This integrated approach ensures the production of consistent, high-performance fertilizers that meet the exacting standards of modern precision agriculture, supporting both crop yield and sustainable farming practices.

.jpg)