Introduction

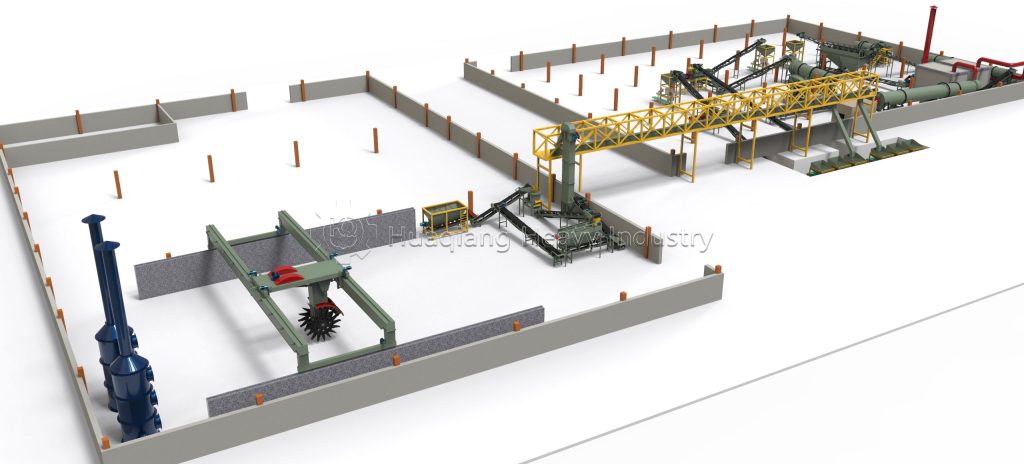

As the global population continues to grow and climate change challenges intensify, sustainable agricultural practices have become increasingly crucial. The integrated organic fertilizer production line represents an innovative approach that combines waste management, resource recycling, and agricultural production. This system utilizes specialized equipment like the large wheel compost turner, chain compost turner, and various wheel compost turner models for efficient composting. The granulation process employs advanced machinery including the double roller press granulator, drum granulator, and specialized organic fertilizer granulator equipment. These fertilizer granulator systems, particularly through drum granulation and double roller granulator technologies, complement the npk production process and npk fertilizer granulator operations, creating comprehensive solutions for global food security challenges while optimizing resource use throughout the production cycle.

System Components and Operation

The integrated organic fertilizer production system is a comprehensive waste conversion platform that transforms agricultural residues, food processing by-products, and urban organic waste into high-quality organic fertilizers. The system typically includes waste collection and sorting, composting treatment, quality control, and product packaging. Through scientific management, these systems not only reduce environmental pollution but also create economic value.

Environmental Benefits

This system significantly reduces greenhouse gas emissions and the burden on landfills. It is estimated that over 30% of the organic waste generated globally each year can be converted into useful resources through such systems. Furthermore, the use of organic fertilizers improves soil health, enhances water retention capacity, and increases carbon sequestration potential, contributing to climate change mitigation.

Economic Benefits

Integrated organic fertilizer production systems create new business opportunities and employment positions. Both small and large farms can benefit from reduced input costs and increased crop yields. These systems are particularly promising in developing countries, where waste management challenges can be transformed into economic opportunities.

Social Impact

By providing affordable organic fertilizers, these systems enable small farmers to adopt sustainable farming methods, thereby increasing food production and income. Community participation in waste collection and sorting also fosters environmental awareness and promotes the dissemination of circular economy principles.

Future Prospects

With technological advancements and growing global interest in sustainable agriculture, integrated organic fertilizer production systems are expected to expand worldwide. Collaboration between governments, private sectors, and international organizations is crucial for scaling up these systems, particularly in regions with limited waste management infrastructure.

Conclusion

The integrated organic fertilizer production system embodies the core principles of the circular economy, combining environmental management with agricultural production. By adopting these innovative systems, the global community can enhance agricultural sustainability while reducing pollution, creating a healthier planet for future generations.

The integrated organic fertilizer production system represents a transformative approach to sustainable agriculture, where advanced equipment like the large wheel compost turner and chain compost turner efficiently manages the crucial organic fertilizer fermentation phase. This sophisticated organic fertilizer production line seamlessly integrates with complementary systems such as the npk fertilizer production line, creating a comprehensive nutrient management solution. The granulation process, whether employing a double roller press granulator for dense pellets or a rotary drum granulator for uniform spheres, demonstrates remarkable versatility. This drum granulation technology within the bio organic fertilizer production line ensures consistent product quality, while the npk production process in parallel lines addresses balanced mineral nutrition needs. The synergy between various wheel compost turner models and specialized fertilizer granulator equipment like the drum granulator and npk fertilizer granulator creates a closed-loop system that transforms waste into valuable agricultural inputs. As these integrated systems evolve, combining traditional organic fertilizer granulator technology with innovative npk fertilizer manufacturing process methods, they pave the way for a more sustainable agricultural future where resource efficiency and food security go hand in hand.