In the NPK manufacturing process, the granulator performs like a “magician,” miraculously transforming powdery raw materials into uniform granules. This specialized equipment is central to the NPK production process, particularly for creating high-nitrogen organic-inorganic compound fertilizers. It is this critical stage of the NPK fertilizer manufacturing process that serves as a key asset for the entire industry’s advancement.

Structural Design: Robust and High-Performance

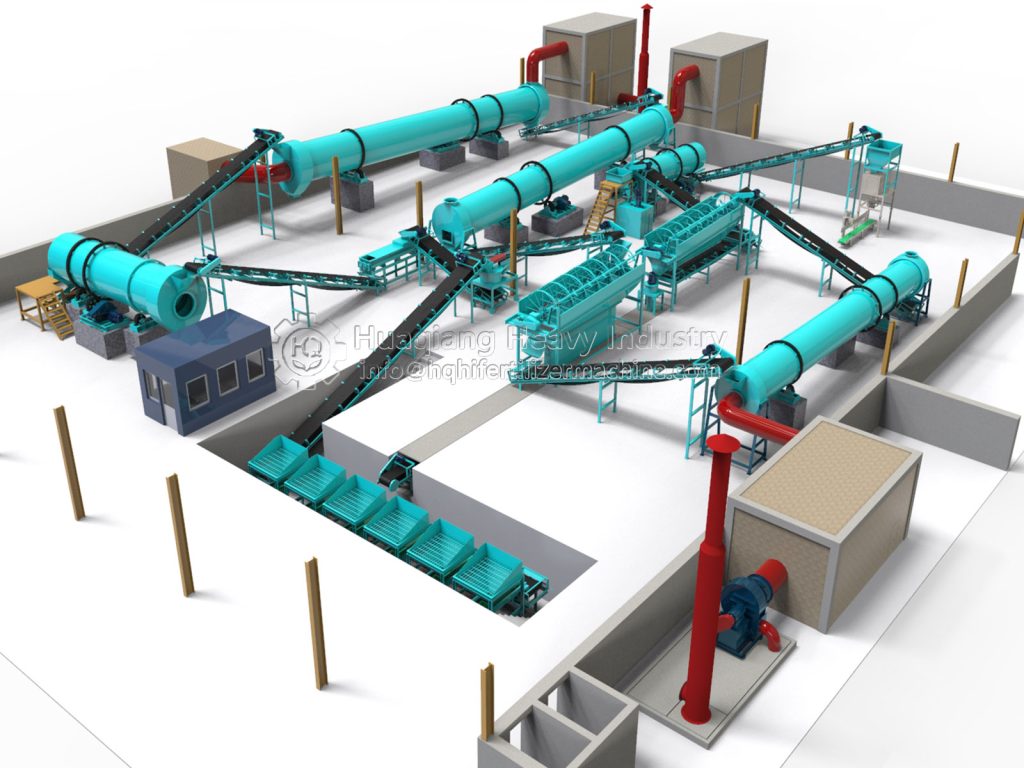

Modern NPK fertilizer granulators feature modular designs comprising several core components:

- Reinforced Frame: Constructed with thickened channel steel welding, providing a solid foundation

- Drum Structure: Heavy-duty steel plate welded drum design ensures long-term operation without deformation

- Innovative Granulation Mechanism: Unique stirring teeth design enables efficient granulation

- Dual Transmission System: Internal coupling soft connection paired with external cast steel gear transmission

Working Principle: Perfect Fusion of Technology and Craftsmanship

As materials enter the rotating drum, the stirring teeth play a pivotal role. This design excels in handling high-nitrogen NPK formulations, effectively preventing material caking while ensuring granule uniformity. The drum’s rotation generates centrifugal force, causing powders to continuously tumble and compact under the stirring teeth’s action, gradually forming ideal granules.

The internal transmission’s soft connection significantly reduces vibration, while the external cast steel gear system ensures stable power transmission. This dual transmission system is the key to the granulator’s ability to operate continuously without failure.

Application Advantages: Tailored for NPK Production

Compared to conventional granulation equipment, this specialized NPK fertilizer granulator offers distinct advantages:

- Minimal wall adhesion when processing high-nitrogen formulas, reducing cleaning downtime

- Superior granule sphericity with over 15% higher yield rate

- 20% lower energy consumption, meeting green production standards

- Modular design simplifies maintenance, lowering operational costs

As the compound fertilizer industry moves toward high-concentration, specialized products, this professional granulation equipment is becoming NPK manufacturers’ secret weapon for competitive advantage. Its exceptional performance and reliability are redefining quality standards in fertilizer production.