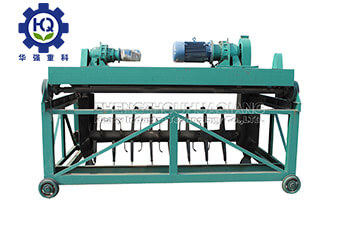

Fertilizer equipment drum screener machine is divided into ordinary screening machine, automatic beating device screening machine. According to the general screening equipment, we specially designed the drum screening machine, which has small screening resistance, small power and standard thickness steel plate. The designed dust cover can remove the powder dust, improve the working environment and protect the environment. This kind of fertilizer equipment after-sale maintenance is simple and convenient, only need to replace the screen.