The market demand for granular potash fertilizer is large, and the development and utilization prospects are broad. Granular potash fertilizer has good physical properties, no dust during loading and unloading, no agglomeration during long-term storage, easy to spread during fertilization, and can also play a role in grade release, improve the utilization rate of fertilizer, and its production meets market needs.

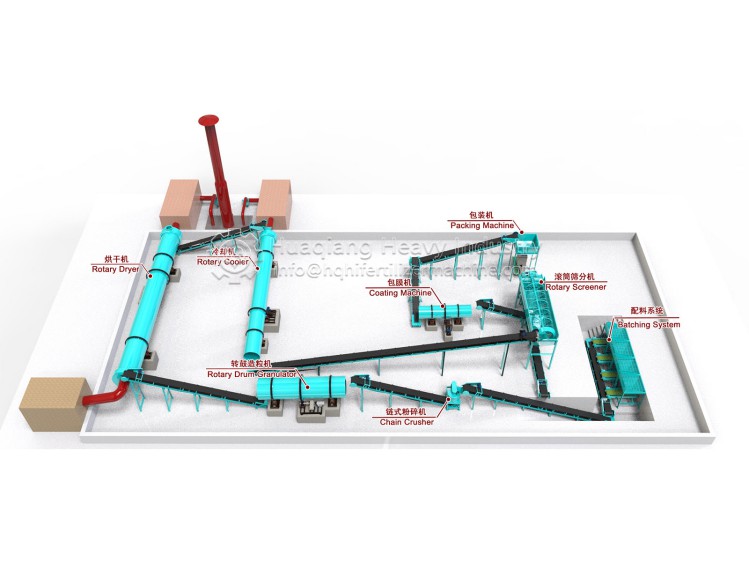

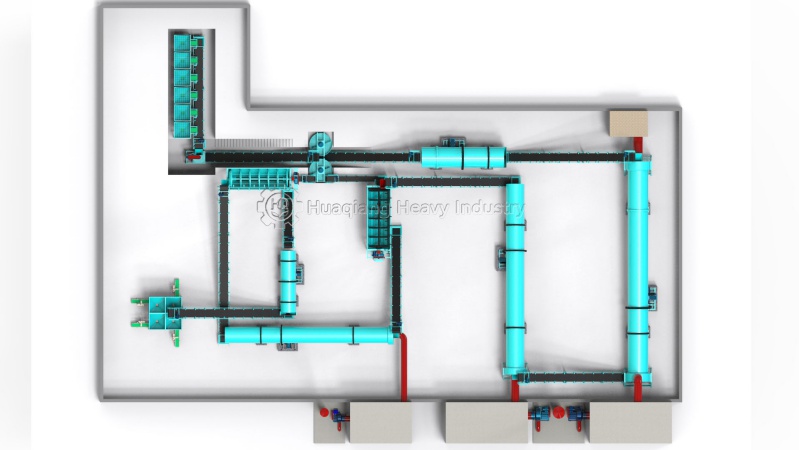

The npk fertilizer production line mainly includes feeder, disc mixer, chain crusher, double roller granulator, drum dryer, drum cooler, drum screener, finished product warehouse, automatic packaging machine, belt conveyor , dust settling chamber, heat exchanger.

The npk manufacturing process is sorting, drying, fermentation, crushing, mixing and packaging. The composition of garbage is complex and varies in thickness, and it needs to be sorted before it can be used as a raw material for fertilizer production. The organic fertilizer production line is mainly the raw materials of organic fertilizers that are crushed, sieved, and then weighed, batched and mixed with the raw materials of the binder and other components to be compatible in an automatic batching and mixing system according to the ratio requirements. The fully mixed materials It is fed into the granulator uniformly and continuously by the belt conveyor for granulation.

The poultry and livestock manure organic fertilizer equipment uses chicken and pig manure as the main raw materials, adds a certain amount of nitrogen fertilizer, phosphate fertilizer, potassium fertilizer, magnesium sulfate, etc., and uses rice bran, yeast, soybean meal and sugar to ferment for a certain period of time as biological bacteria. Under the action of mixed fermentation. The organic fertilizer can eliminate soil compaction, increase the yield of crops, and has the function of accelerating ripening. The fertilizer can be widely used in agricultural production, has low application cost, has no environmental pollution, and is beneficial to soil improvement.

Utilize the npk fertilizer production line to produce fertilizers containing sufficient NPK fertilizers, which help plants grow, increase the yield of seeds and fruits, and improve the quality of leaves and fodder crops. They are an inevitable part of our daily life, so it is important to produce high-quality NPK fertilizers.

.jpg)

.jpg)

.jpg)