How to use self-propelled fermentation turner to treat organic fertilizer raw materials

organic fertilizer production line

organic fertilizer granulator

Whether it is organic fertilizer processed by the compost turning machine or NPK fertilizer, dryers are often used in the production and processing of fertilizer plants.

Precautions for installation of NPK production line of dryer

It is natural to use special fertilizer production equipment to produce fertilizer, but due to the particularity of fertilizer equipment, the working environment of fertilizer equipment is relatively poor, and sometimes the equipment frequently used is severely corroded less than a year ago. Normal loss is inevitable, but necessary equipment cleaning and maintenance can prolong the service life of the organic fertilizer crusher.

When crushing raw materials, the raw materials should not have large solid substances, and the organic fertilizer raw materials have stones or even iron blocks, which will seriously damage the high-speed rotating crusher rotor. Only by ensuring that the raw materials are clean and free of impurities, the fertilizer processing equipment in each process will not be affected.

During daily use, the organic fertilizer crusher shall be maintained in a timely manner, and a special person shall be designated to take charge. The organic fertilizer grinder must be thoroughly inspected regularly to prevent problems. Only in this way can problems be found and solved in time. It must be known that the shorter the maintenance cycle of the machine is, the smaller the possibility of error is, and the more reliable the operation of the equipment itself is.

From the perspective of the long-term benefits of the organic fertilizer crusher, although the performance of the organic fertilizer crusher is stable and the mechanical parts are solid, the machinery itself is easy to wear due to the increase of working intensity in daily work. Therefore, in the regular maintenance phase, especially in the work, we should also do a good job in equipment maintenance and try to operate according to the operating instructions of the organic fertilizer granulator. Learn the maintenance method of organic fertilizer crusher, and take reliability and safety as the leading maintenance method to ensure the safety maintenance of maintenance personnel.

For a long time, the safety of organic fertilizer crusher prevention depends on its reliability. Therefore, it is believed that the more prevention work is done, the shorter the maintenance cycle is, the more reliable the mechanical equipment is.

The mechanical equipment relies on the motor and reducer to ensure the power source, and is regularly filled with lubricating oil to better ensure their operation. There are many types of lubricants, so it is necessary to select the appropriate oil according to the different climate and mechanical driving principles. According to the wet and hot environment in the north and south, cycloidal pin gear reducer and ZDZQ series reducer and other needs, selecting the appropriate lubricant can better ensure the operation of the equipment. In addition, adjust the amount of charging oil when filling the fuel to avoid too little effect or waste.

Different equipment has different capacities, so the equipment shall be used reasonably according to the processing capacity. For example, when supplying feed to the warehouse, let the forklift slowly drop the material to avoid breaking the equipment. Raw materials cannot be fully filled during mixing. Materials shall be added after starting the mixer to prevent excessive mixing resistance and equipment damage.

In fact, looking at these operating regulations, many of them are related to details. In a word, the organic fertilizer production equipment must be well managed in order to operate better and bring us more benefits.

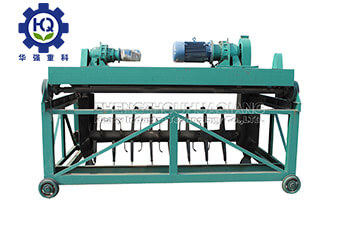

1. Organic fertilizer continuous trough dumper (single machine), models are 4m, 6m, 8m, 10m. The fermentation cycle is 7-8 days, the daily processing capacity is 800-1000 cubic meters, and the annual production capacity is 10000-20000 tons. Multi tank fermentation can increase production by 20000-50000 tons, and organic fertilizer can be fully fermented, which is suitable for granulation by rotary drum granulator.

The organic fertilizer equipment is a good project for many people, because it not only conforms to the national environmental protection regulations, but also is an environmental protection machinery.

Matters needing attention when making granules by organic fertilizer granulator

(1) At least two powder silos to be granulated shall be provided so that the granulator does not need to stop when the formula changes.

(2) Before materials enter the granulator, effective iron removal device must be installed to protect the granulator.

(3) The organic fertilizer granulator shall be directly placed on the cooler, and the crusher shall be placed under the cooler.

(4) To prevent particles from falling from the bottom of the silo, a vertical spiral chute is installed in the silo.

(5) Finished products shall be packaged behind the finished product warehouse.

Fertilizer dryer is suitable for the processing of organic fertilizer and NPK production line, and each structure of it is very important. Organic fertilizer dryer also has certain technical requirements when processing. So, what should be paid attention to when drum dryer is producing organic fertilizer?

Chicken manure compost turning machine can promote the rapid decomposing of livestock and poultry manure and other inorganic wastes. The equipment adopts continuous aerobic fermentation process to rapidly decompose, dewater, sterilize and deodorize the inorganic wastes to achieve harmlessness and resource utilization. And the goal of reduction and disposal, low power consumption and stable product quality.

Producing the organic fertilizer granulator using the fertilizer granulator machine.Different type and model of organic fertilizer granulator machine can be used to produce the organic fertilizer granulator.How to improve the granulation rate of the rotary drum granulator?

In the fertilizer manufacturing process,the new type organic fertilizer drum granulator is a common granulator,which mainly uses high-temperature steam to make raw materials humidified to the granulation state.After the granulation of Huaqiang new type type organic fertilizer drum granulator,the particl temperature is very high.In the next drying process of organic fertilizer particles,the heat energy consumption of drying is saved,which is not efficient and engery-saving,and the granulation rate is up to more than 90%.

In order to improve the granulation rate of the new type organic fertilizer drum granulator in organic fertilizer production line,in addition to selecting a high-quality product,the granulation rate and output of the granulator can also be improve the granulation rate of new organic fertilizer drum granulator:

First,the time and frequency of material rolling in the new type of organic fertilizer drum granulator is the primary factory to determine the pelletilizing rate and particle roundness.The principle of rotating drum granulation is that the material depends on the surface tension,the appropriate liquid phase,the extrusion pressure generated by roller press which the roller press granulator machine is also to be designed and used in npk fertilizer manufacturing process in most of time,and correct movement direction of the material in the granulator is centered on small particles,which absorb and adhere to the ball in the rolling process.The higher the rolling frequency in a certain period of time,the higher the pelletilization rate is,and the rounder the particles will be after forming.In the process of production,we have encountered two situations due to the different friction between the material and the barrel wall of the granulator.

1.The internal surface finish of te granulator is large,which reduces the friction between the material and the cylinder wall,and weakens the upward movement force of the material.If the material does not roll,it will not produce particles.In view of this situation,we can solve it by adjusting the rotating speed of the new type of organic fertilizer drum granulator and installing a small-scale plate inside.

2.The material in the organic fertilizer drum granulator sticks to the walll seriously,the friction between the material in the granulator and the cylinder wall is enhanced,and the material in the granulator is lifted too high,which causes the material to be thrown down from the top,until the particles formed are not round and too many large particles.We think there are two reasons for this situation:on the one hand,there are too many stickly materials ,which we adopt.On other hand,the inside of the granulator is not smooth,which can be solved by changing the inside material and increasing the inside finish of the granulator.

.jpg)

The design of npk fertilizer production line by rotating drum granulation is that there is a steam pipe embeded in the feed bed,and a spray is arranged above the feed bed.Under the condition of stable production supply,the saturated steam provides part of water while providing heat,which increase the moisture content of the material.Through the use of steam,the temperature and viscosity of the material are increased,so that the moisture content of the mateiral can be reduced in the process of balling,thus reducing the drying load, and the liquid phase distribution of adding steam can be more uniform than adding water. Only when the liquid phase of the material is insufficient and the material is unstable, can the water be added as a supplementary means. In the process of production, we have encountered that because of the unreasonable installation of the steam nozzle and the uneven distribution of the liquid phase of the materials, the places where there are many liquid phases of the materials are stuck into a big ball, and the places where the liquid phase is insufficient, the materials are difficult to form a ball, which affects the formation of the particles. In view of this situation, we can increase the steam nozzle to improve the steam receiving area of materials.

In conclusion,in order to improve the granulation rate of the new type organic fertilizer drum granulator,it is necessary to stickly control the water content,carry out the water ratio according to the provisions of the fertilizer equipment manufacturer,and pay attention to the methods in the production process at ordinary times,so as to improve the granulation rate and output of the new type organic fertilizer drum granulator.

Fertilizer promotes the development of ecological agriculture, and the demand is huge. Investment in building fertilizer plants has become a popular project. Some investors want to build small-scale fertilizer manufacturing process to save costs, while some investors in fertilizer plants are going to build large-scale fertilizer plants to save unit production costs.

So what should we pay attention to when purchasing fertilizer manufacturing process plant? Here are some notes.

Powerful organic fertilizer production equipment enterprises can customize their own equipment configurations for different customers according to their needs, and users can choose their own equipment according to their own needs. Zhengzhou Tianci Heavy Industry Machinery Co., Ltd. We provide customers with process design, equipment manufacturing, installation and commissioning, with full one-stop services. We are a leading agricultural equipment manufacturer in China, has strong technical strength in fertilizer machines. We have exported to many countries, India, Korea, Vietnam, Pakistan, Malaysia, Kenya, Sudan, Egypt, Algeria, Russia, Ukraine, Turkey, Spain, etc. Any question, welcome to contact us.