Equipment Overview

The rotary drum granulator stands as a cornerstone in modern fertilizer production, particularly within NPK fertilizer production process lines. This essential fertilizer production machine utilizes mechanical motion and precise process control to transform raw materials into uniform granules through efficient drum granulation. While alternative methods like fertilizer granules compaction using a specialized fertilizer compaction machine exist, the drum granulator remains preferred for its high-capacity continuous operation and superior product characteristics.

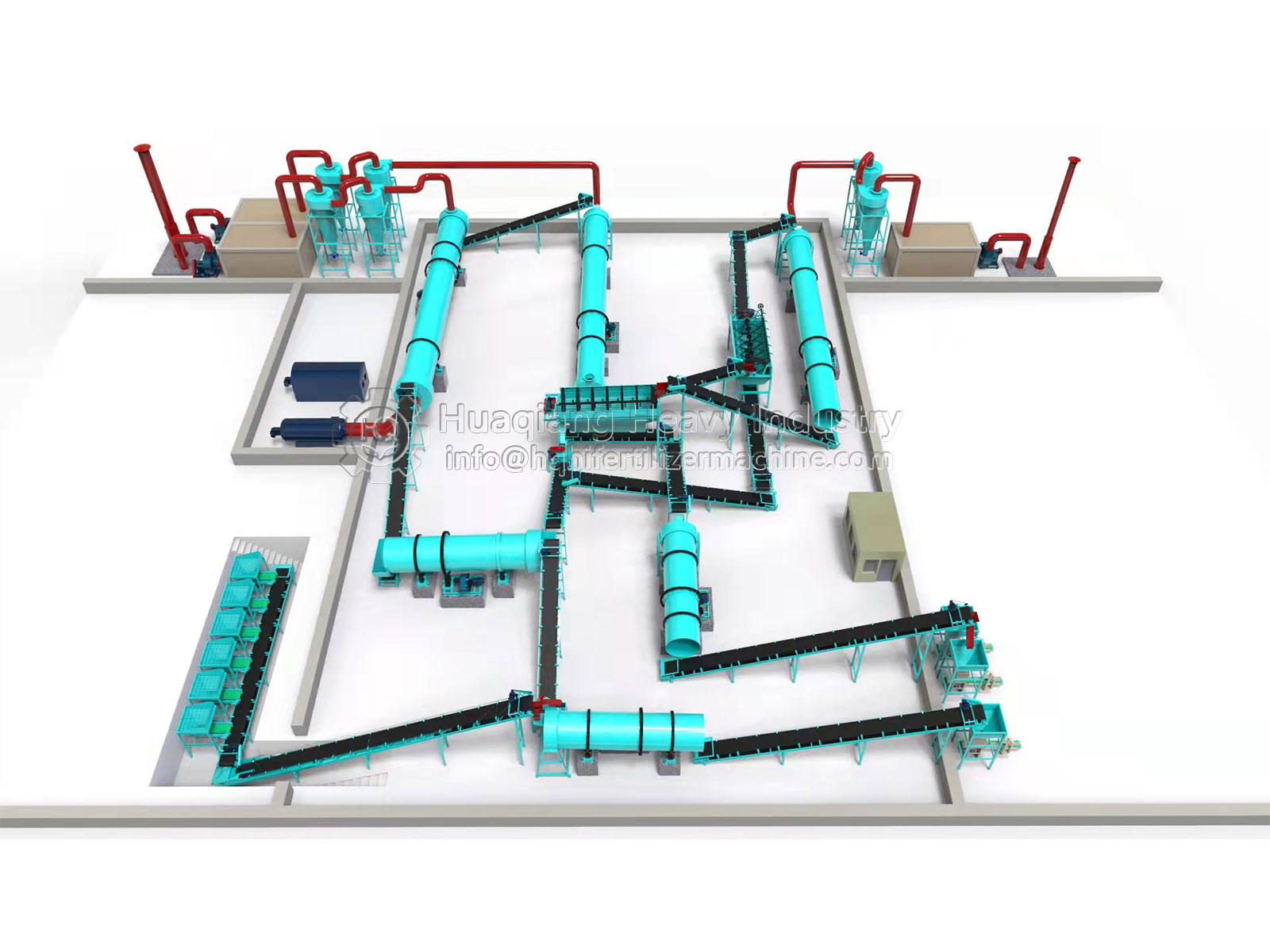

Within the comprehensive NPK manufacturing process, the rotary drum granulator ensures optimal nutrient blending and particle formation. Its versatility extends beyond NPK production line applications to organic fertilizer manufacturing machine configurations, demonstrating remarkable adaptability across different production requirements. The integration of this equipment with complementary machinery like the fertilizer compactor in some processes creates complete manufacturing systems that deliver exceptional granule quality, structural integrity, and production efficiency, making it an indispensable component in modern fertilizer manufacturing operations worldwide.

Working Principle

The operation of a rotary drum granulator can be divided into three main stages: First, basic raw materials such as nitrogen, phosphorus, and potassium are uniformly mixed with appropriate binders. Next, the mixed materials enter the rotating drum where they gradually agglomerate through continuous rolling and friction. Finally, by precisely controlling process parameters like moisture, temperature, and rotation speed, uniformly sized fertilizer particles with optimal strength are formed.

Technical Advantages

Modern rotary drum granulators offer numerous technical advantages: A pelletizing rate exceeding 95% ensures efficient utilization of raw materials; the precisely controlled granulation process produces fertilizer particles with ideal strength; corrosion-resistant designs using stainless steel liners or rubber linings adapt to various corrosive materials; highly automated control systems enable continuous and stable production operation; innovative self-cleaning designs significantly reduce equipment maintenance requirements.

Critical Role in NPK Production Lines

In NPK compound fertilizer production lines, the rotary drum granulator plays a vital role: It enables precise proportioning of raw materials, ensuring uniform nutrient distribution; significantly improves product physical properties including particle strength, uniformity, and flowability; effectively reduces production costs while enhancing product market competitiveness; and simultaneously meets increasingly stringent environmental requirements for green production.

Industry Significance

With the growing global agricultural demand for efficient and environmentally friendly fertilizers, technological innovations and process optimizations in rotary drum granulators will continue to drive progress in the entire fertilizer industry. As the core equipment in NPK fertilizer production lines, its performance directly affects the quality of final products and production costs, thereby providing crucial support for global food security. In the future, with the development of intelligent and energy-saving technologies, rotary drum granulators will play an even more important role in the fertilizer industry.