Discover the fascinating technology behind disc granulation systems

The Marvel of Disc Granulation Technology

In the fascinating world of modern manufacturing, disc granulation stands as a remarkable process that transforms fine powders into uniform, spherical pellets with almost magical precision. This sophisticated NPK fertilizer production technology harnesses the power of centrifugal force and material friction to create perfectly formed granules essential for numerous industries.

At the heart of many NPK production line systems, the disc granulator represents an engineering marvel that efficiently converts raw materials into valuable products. The complete NPK fertilizer production process integrates multiple stages of processing, each playing a vital role in creating consistent, high-quality granules with precise physical and chemical properties.

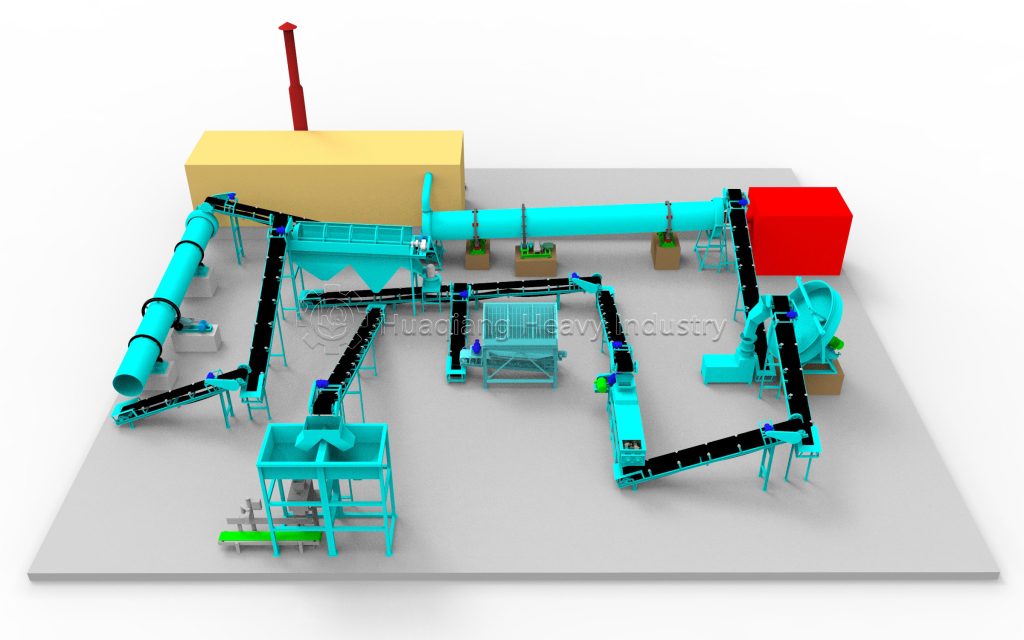

The Complete Granulation System: A Symphony of Specialized Equipment

A comprehensive disc granulation production line represents a harmonious integration of specialized machinery, each component performing a critical function in the transformation process. This sophisticated system exemplifies advanced NPK fertilizer production technology at its finest.

1. Raw Material Preparation

Crushers and screening machines pre-treat materials to ensure uniform size and purity

2. Mixing Equipment

Blends raw materials with binders or water for optimal granulation consistency

3. Disc Granulator

The centerpiece of the operation where centrifugal force forms perfect spherical granules

4. Spray System

Precisely mists water or binders to control moisture levels during formation

5. Drying Equipment

Removes excess moisture to enhance product stability and shelf life

6. Cooling System

Lowers temperature to prevent deformation and prepare granules for handling

7. Screening Equipment

Separates granules by size to ensure consistent product quality

8. Packaging Unit

Automatically weighs and packages the finished product for distribution

9. Control System

PLC-based automation monitors and adjusts parameters for optimal performance

Why Disc Granulation Stands Out in NPK Production

The disc granulation method has become the preferred choice in NPK fertilizer production process systems for several compelling reasons. Its exceptional efficiency in forming uniform granules, remarkable adaptability to various raw materials, and consistent output quality make it indispensable for modern manufacturing.

Within an NPK production line, the disc granulator offers unparalleled flexibility, easily accommodating formula adjustments to meet specific product requirements. This versatile NPK fertilizer production technology enables manufacturers to quickly respond to market demands while maintaining the highest quality standards.

The advantages of this sophisticated approach extend beyond mere efficiency:

- Superior Product Quality: Produces uniform, spherical granules with excellent physical properties

- Operational Efficiency: High throughput with relatively low energy consumption

- Process Flexibility Easily adapts to different formulas and raw material characteristics

- Environmental Benefits: Optimized resource utilization reduces waste generation

- Economic Advantages: Lower operational costs and higher product value

Modern NPK fertilizer production technology continues to evolve, with disc granulation systems at the forefront of innovation. These advanced systems represent the perfect fusion of mechanical engineering and process technology, delivering exceptional results across numerous industries from agriculture to specialty chemicals.